Everything posted by Zed Head

-

77 280z rust free original unmolested parting out in Las Vegas

Didn't this horse get turned in to sausage just a short while ago? Selling parts from a car you don't have title to is what chop shops do. You can call it taking a risk, or everybody does it, or what else could I do, but it's all the same. Big picture, since it was a divorce, you're probably doing somebody's dirty work. Tainted parts.

-

Crank position sensor

The CAS doesn't have a resistance that you can check, like the pickup coil does in an EFI 280ZX. It's transistorized. Power supply to the CAS is important. Many ways to have problems with Megasquirt. Some people can't get a known-good CAS to work well with Megasquirt. It takes some tricks. If you insist/persist though, like JSM says, that piece just gets stuck and can be rocked or pried off. No need for a puller. But, better to describe your "big problems". I would stop disassembling your CAS now, especially if you barely know what an ohm is. Really seems like you might be on the wrong path.

-

1973 Rebuild

But, on the other hand, there's really nothing wrong with staking the old nuts. They're not really "wrong". And it's simple to do. What are the odds that you'll be removing that nut over the remaining life of the car? Tiny.

-

1973 Rebuild

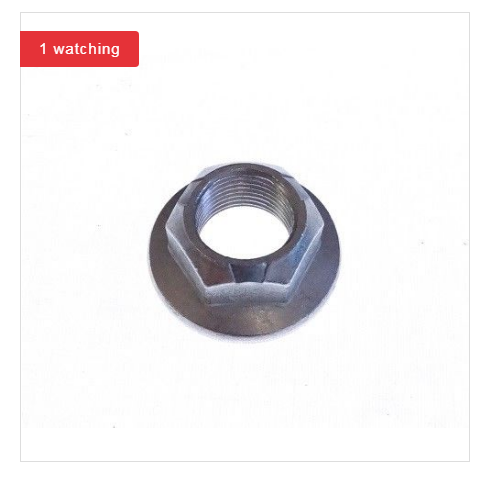

Looks like you might be right. Self-locking nuts are distorted at one end to pinch the axle shaft and threads. You can see the press marks on this eBay image of the proper ZX lock nut. Your nut has the raised ridge, for staking. Here's what appears to be the right part number - 43262-W1200 Google it and you'll find some stories about these guys selling the old nuts in place of the new. MSA's page suggests that the 79-93 NA coupes used staked nuts but that doesn't seem right. Anyway, good luck. Your local Nissan dealer might have them on the shelf. https://www.ebay.com/i/322923795491?chn=ps http://www.thezstore.com/page/TZS/PROD/23-4572

-

Engine Cradle???

Tippy. Watch for tiny rocks. Nice on space though.

-

Engine Cradle???

The wood HF dolly works great but the wood will slowly bend and sag if the weight is applied toward the center. Then the casters will rotate outward and it won't roll well. Easy to reinforce, or just make sure that the actual load points are by the casters.

-

WTB cheap 280z injecters

What do you mean by "working"? Do they need to be flow-balanced? Or are you just testing fit and electrical? Would some old junky injectors work? Most larger injectors that people like to use are 11 or 14mm o-ring style installations, not hose based. The stock injectors use an EV1 connector also, not the most common. You can get newer style injectors for cheap at most wrecking yards.

- The pesky odometer

-

New key by code in glovebox

I really did spend a lot of time on that lock problem. It was a pain. Then there was the window roller problem... I think that you could reach the critical parts through the gap between window and door also. Probably better and you might be able to see what you're squirting. Drop the window just a bit and your nozzle will be below the glass. Sounds like you already removed the panel, but if you decide to take another shot.

-

L28 Stroker Build - I need your advice :-)

Those are wide spec ranges. Builders tend to open the gap if they expect a hot running engine. Even if you had stock pistons you'd probably still not have a clear answer. Those KA pistons aren't that much different from stock, and you don't have a turbo or anything special. Just avoid the small number and you'll probably be fine. Another interesting topic that we can spend lots of time on though. Thanks. http://www.acl.co.nz/wp-content/uploads/4-Compression-Ring-Gaps-For-High-Performance-Engines.pdf

-

New key by code in glovebox

I had a similar problem on my sat-for-a-long-time 76. I used to turn the key and hold pressure until it moved. Sometimes I gave up. One of my keys is still twisted. Doesn't sound like a key problem since the once the cylinder moves the tumblers are already fit to the key. One clue to me that it was a sliding surface problem inside the door poarts, helped by lube, was that it was worse when it was cold. I think that I adjusted the length of one of the rods also, the threaded plastic piece. Don't know how it got out of adjustment but moving it helped. Can't get to anything without removing the panel, unless you take out the striker plate, I think. Even the door handle and lock cylinder are attached from the inside. Then you can just hose lube in and hope you hit something. You could probably just take one screw out and bend a WD-40 tube. And hope. I spent a lot of time inside my doors but eventually got them working right.

-

Rear Brake Line Rubbing Against Drive Shaft

When bending hard lines you won't know if you have an issue until you have an issue. If you want to buy some time until you get a chance to swap the wheel cylinders you can buy pre-fitted specific lengths of hard line at the auto parts stores and bend them to the application. Fresh tubing bends much easier than aged, already bent tubing. "Work hardening". Sounds like you don't want to get in to the shoes and hardware right now.

-

Rear Brake Line Rubbing Against Drive Shaft

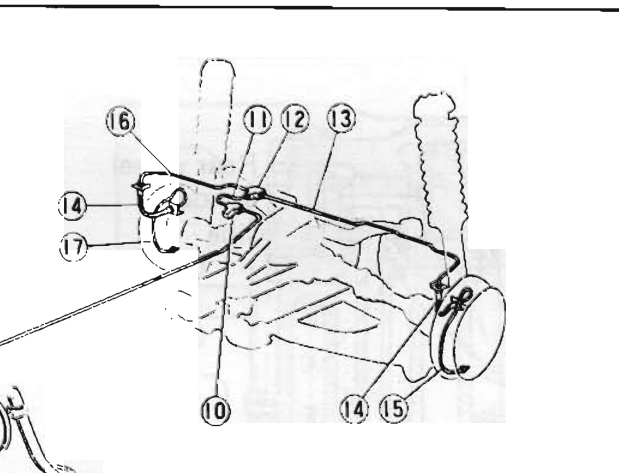

Looks to me like somebody put parts on the wrong sides. Probably wheel cylinders, and/or hard lines. The hydraulic hose should have only a smooth 90 degree curve, not a 90 then the 180 that your picture shows. The hose is entering its second connection from the wrong direction. Just guessing, based on the FSM diagram and your problem. 11" is the long hose. I remember your problem from the last time.

-

Fuel damper leaking. Can’t find replacement. Is it required?

Found the one I was thinking of -

-

Fuel damper leaking. Can’t find replacement. Is it required?

There is at least one thread on the site somewhere about a later model damper that was used as a replacement. I think it was available on Rockauto. Maybe search the words using the site's search engine, or use Google and "site:classiczcars.com" as a term. I think that it might also make the pump last longer. It damps the pressure pulses from the injectors opening and closing too.

-

82 NA EGR Valve

Pretty fast. I had one that made a farting noise sometimes as the actuator vacuum pulses changed. That's a fairly fast frequency.

- L28 Stroker Build - I need your advice :-)

-

240 260 engine

The FSM's are here - http://www.classiczcars.com/files/ A little difficult to figure out at first. The links are on the right and sometimes you'll get a "no file here" message. Plus if you click on "Resources" it takes you to the "Community" page for some reason. You can only get there by hovering over Resources. At least on my system. Windows 7 with Chrome. You'll want to download some of these even if you get a ZX engine. Assuming you meant 280ZX and not 300ZX. That would be the VG30 engine, a whole different game.

-

L28 Stroker Build - I need your advice :-)

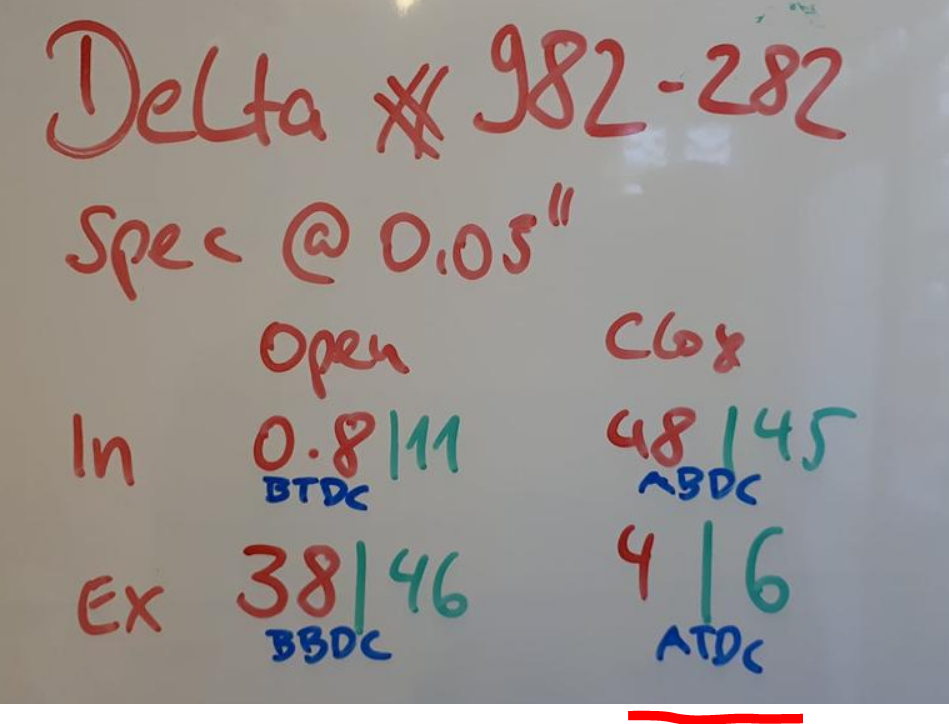

Actually it is "too" soon if you're comparing to the cam card. I just look at the B or the A in BTDC (before top dead center) and ABDC (after bottom dead center), and the like. If the B number is bigger than the cam card, then it's sooner, more advanced, more early, more "before". But if the A number is bigger then it's later, more after. The numbers are in relation to the "dead center" point chosen. You can recalculate them in other terms if you want. The ATDC number is the one that's not early. It's a bigger "after" number. I missed it. Two bigger B's, one smaller A, and the bigger A (the later than the card timing event). Edited (again) - don't know my A's from a hole in the ground. Original version in madkaw's quote. Delta cam must have large tolerances in their specs, or sloppy equipment. Most people wouldn't check the quality of the job like german240 did. Disappointing that they couldn't give a good answer to the question.

-

'75 280z can't get spark

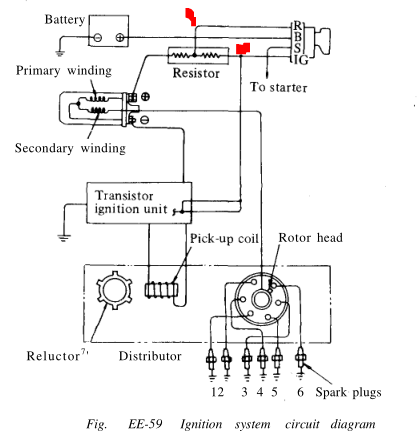

Since you had the problem before you replaced the distributor, a problem with the ignition switch seems possible, as mentioned. Since you removed the ballast resistor. The R terminal at the switch. People who have had that problem have worked around it by turning the key very slowly to the Start position. But you should check for power to the coil during Start also, it's easier. Don't forget to check the distributor body's ground to the engine also. That's where the ignition module ground is. Check for power at the coil at Start, and the ground from the distributor body.

-

240 260 engine

The L26 has a longer stroke. The L24 crank and pistons, etc. in the L26 block will make an L24. Specs are in the Engine Mechanical chapter is you want to be sure.

-

Im at wits end please help

It ran great for while but now it doesn't and it spits and pops. Spitting and popping is often a sign of a lean mixture. Could be a vacuum leak or it could be the carbs need tuning to add more fuel. You could do some tuning, but make sure you know where you started so you can go back. You can get pretty close with ignition timing by eye. Put the damper pulley mark on 10 degrees and rotate the distributor until the points are just about to open. Make sure that you're aware of the rotation direction. Maybe the distributor vacuum advance got stuck in an advanced position.

-

L28 Stroker Build - I need your advice :-)

Looks like all of your numbers are early, which could be due to your new chain and sprocket. I can't really wrap my head around the duration calculation but that would be determined by the cam profile. Maybe you could calculate that to see what it comes out to. Total lift would be a specific number that should match also. You'd have to know what the shop's tolerances were to know if it's "fine" by their standards. +/- how many degrees is "okay". Maybe they have wide specs.

-

Intake / exhaust manifold spacers: necessary?

Funny that even MSA can't really figure out what to call them, and both attempts are kind of wrong. Nissan called it a "yoke", probably because it spans a distance to clamp two separate parts together. But it's really a clamp. It's a specifically designed piece of metal. It's cone shaped to clamp the two manifolds to the head, via just the edges of one side, and to allow the nut to ride on a curved surface on the other side. Probably to allow for differences in thickness between the two manifolds. A flat piece of metal, like a thick washer, would be caulked, and put a side load on the stud or bolt if the two manifolds were not exactly the same thickness. Anyway, that's the way I see it. For as crude as it looks, the yoke is actually a subtle piece of engineering. Post a picture of the flat washer/spacers if you can. Let's see if they have any shape to them. http://www.carpartsmanual.com/datsun/Z-1969-1978/engine-280z/manifold-egr/from-aug-76/28

-

Rolling Shell with no VIN

One good thing that came out this thread is that I went out and located my stamped VIN in the firewall. It matches the documents and the tags! Yay. So, someday, when 1976 280Z's are collectible, I'll be ready. I've realized that much of tzag's energy might come from the fact that he has done many many body, chassis, parts, etc. swaps over the years, as he states in previous posts. He's basically defending his past. Really, he could have just said "gee whiz, I've done a ton of these types of swaps over the years, maybe I should see what these guys think about that". No need to wizz a bunch of people off just because they're arguing the other side. As Namerow implies, this stuff goes on around the world. There's legal and there's opinion. You buy based on opinion. The legal part is a formality.