Everything posted by Zed Head

-

Steering Rack Disassembly and Refurb

Then what happened? Are the holes through-holes or divots? Any parts get loose?

-

Potentiometer

Did you measure resistance across the terminals? Should have been about zero at one end of the rotation. And did you solder two terminals together as one leg of the circuit? I don't think that you need to do that. Just measure resistance across two terminals that show zero and a higher number,with knob rotation, and use those two for the circuit. We're not really using it as a potentiometer, it's really a rheostat. http://www.resistorguide.com/rheostat/

-

Bringing a 1977 Z back life

The injectors are designed to work with no clamps. The barb locks the hose on. There's a full procedure shown near the end of the Engine Fuel chapter. They just press on, it's easy. 5/16" hose. Edit - they actually used too many clamps, marked in red. They are the bad kind though, so better clamps for the rail connection is a good idea. Before you install the injectors it might be worthwhile to flow test them. Connect the hoses and electrical and power the injectors. Compare the volume of fuel from each.

-

L28 280Z Car engine problems!!!

Don't assume that it's off by "180". There's nothing special about 180 degrees. The tang and slot are meant to fit only one way even though they look like they could go 180 off. You'd have to force worn parts together to do that though. If you removed the oil pump, it's more likely that you installed it a gear tooth or two off. It's super easy to check though. Set the timing mark on about 10 degrees on the compression stroke and see where the rotor is pointing.

-

I hate Chinese "Metal"

My point, as it always has been, is that people like you are focusing on the wrong target. You're getting played for suckers by the manufacturers selling you cheap dangerous products. If you don't want Made in China, then don't buy the parts. When you're buying your new Nissan tell the salesperson that they're going to need to replace the jack before you buy the car. Send Nissan a letter describing how their jack fell apart and almost injured somebody. The law requiring country of manufacture to be clearly ID'ed on products was passed for people like you. But you're not using it. Where's the picture showing that the rusty rotor was made in China? You don't even know, you just use China as the foil for all of your frustrations with the world. Then try to bring others in to start a session. Post that picture or some evidence that the rotor was Made in China.

-

L28 280Z Car engine problems!!!

As site says it should start without any of those broken items. Except for the BCDD and the dash pot they are all to make cold starting and running easier but shouldn't stop it from starting. Maybe add some details about what it sounds like when it's turning over. You said that you have spark and fuel. Are you even getting a pop? Spark plus gasoline almost always gets at least a pop.

-

I hate Chinese "Metal"

The manufacturers LOVE customers like this. They can do whatever they like, take your money, and put a little stamp on the product to divert your attention from the the people truly responsible for the poor product - themselves! Nissan spec'ed the product, sent the specs to a Chinese company so it could be made cheaply, then took your money, now you're blaming China! How much better can it get. I'll bet Takata blamed China also, for defective air bags. NASA probably blamed China for a defective O-ring. China meddled with our last election, not Russia. Russia used computers Made in China. It's Nissan! Nissan sold you the defective product. Nissan is responsible.

-

Hesitation during acceleration

No codes, even in 1982. In the FSM troubleshooting charts the last item, if you can't find any other cause, is often "replace ECU". Hard to say. Somebody might have an inexpensive used ECU. Borini63 sells a lot of 280ZX parts. @borini63 Does you new distributor come with a module? You can wire up a GM HEI module if not, for about $25.

-

Hesitation during acceleration

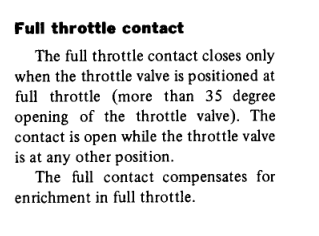

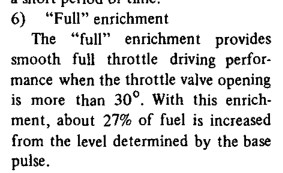

For the 280Z's the TVS is supposed to send the signal to the ECU to add an extra 27% of fuel over the base. Maybe it's not the TVS thats' the problem but the circuit in the ECU that uses it. Maybe you have a bad ECU. I can't find the percentage of fuel for 1982, so copied 1976 to show it. This is from 1982 - This is from 1976 -

-

Hesitation during acceleration

I think that you'd have to make it super rich everywhere else to overcome a stuck vane. It's more of a dead end than a dead spot, I think. Air flow blockage might factor in also. And it was just a thought. Could be something else. Never seen a stuck vane on this forum though, so that would be a new one.

-

Hesitation during acceleration

This is the most descriptive description so far. Stuff to ponder. Nothing comes to mind. An alternative ,or complementary (practicing my words), description might be that it "bogs" in 3rd gear at a certain RPM, if the gas pedal is held to the floor, but picks up again if the pedal is released a bit. It feels familiar, back from my carb'ed car days. When you release the pedal, you're throttling the air flow. Maybe making it match a stuck AFM vane. That just came to mind. The AFM vanes have been known to get stuck. They're delicate, meant to respond only to air. A stuck vane would cut air flow slightly, but reduce fuel enrichment, a lot. The air would slide by, but the ECU would only see vane position. You might check that.

-

Car worth? How much would you pay?

What year is it? VIN? No offense to the late model 240Z owners, but as we've seen here, the early 240Z's have more inherent worth to certain potential buyers. Make sure that you see and get all of the interior parts. They're hard to find. If they're not there, use it as a haggling tool.

-

I hate Chinese "Metal"

Might be chasing your tail 246... Edit - actually, these guys might make the rotors - http://www.advics-na.com/AdvicsPages/global network.aspx The globe is global now. These guys, the pads - http://akebonobrakes.com/OEM https://en.wikipedia.org/wiki/Akebono_Brake_Industry

-

Hesitation during acceleration

Trial and error is the way. With mine, I can kill the engine easily by adding too much fuel, by adding too much resistance. The way I've set mine is just by throttle response. At full throttle the ECU adds a lot of extra fuel via the signal from the TVS. It's mid-range RPM and throttle that the potentiometer will have an effect. The typical lean problem is mid-range, idle and full throttle will be fine, but mid-range will stumble and hesitate, maybe even pop back through the intake manifold. I'm not familiar with the zcardepot device. Do you know what the resistance range is? Is that the one you got?

-

I hate Chinese "Metal"

Post a picture! We love pictures. Make sure you include the "Made in China" stamp.

-

Need used throwout bearing

Check out the Economy bearings at Rockauto. $11 to my house. http://www.rockauto.com/en/catalog/nissan,1976,280z,2.8l+l6,1209226,transmission-manual,clutch+release+bearing,1968

-

1971 HLS30-14938 "Lily" build

I've been surprised at what those little ultrasonic cleaners will do. Sometimes they do a lot, sometimes they don't do anything. Vinegar as a derusting agent also. Is that rust, or just old brake fluid goop? If it's goop, maybe soak it in some carb cleaner. Might destroy the rubber though, if there's rubber in there. Or maybe use the same trick that's used for pilot bushings. Pack grease in to the other end, put a cylinder that fills the hole in to it, and hit it with a hammer. Create a burst of hydraulic pressure.

-

Temp Gauge Warning Idiot Lamp

I've often thought that idiot sounds would be better. We have idiot sounds for the lights and the key in the ignition. A couple more sounds for temperature and charging, plus the lights to indicate which problem, and the odds of surviving it increase. How about a cylinder killer, like they use on the newer cars? Kills injection for half the cylinders to drop the heat load.

- VINTAGE Z auction in JAPAN

- Transistor Module swap *PLS HELP*

-

Upgrade electric system, alternator, Fusible Links, remove External Voltage regulator

That is a lot of nice modernization. What's going on with the red light and the RPM?

-

Transistor Module swap *PLS HELP*

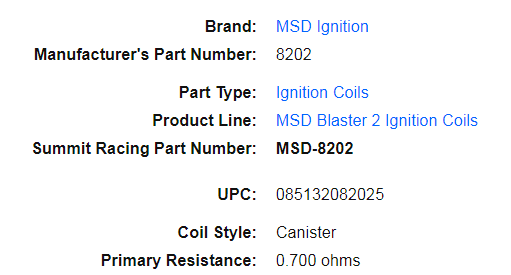

You can get them at any auto parts store for about $25. BWD seems like they make decent parts. Or you can get AC Delco for about $55. Rockauto has a wide selection also. Don't forget the coil. If you want to use the whole GM setup, get the module and external coil for a 1977 Nova with the 6 cylinder engine. Or just get a good coil with about 0.6 to 1.0 ohm primary circuit resistance. The 1978 280Z coils are in that range and will fit the bracket better. You'd have to make a bracket for the GM coil. https://www.oreillyauto.com/shop/ignition---tune-up-16776/ignition-module-control-unit-ignitor-12521/1977/chevrolet/nova?q=igntion module https://www.oreillyauto.com/shop/ignition---tune-up-16776/ignition-coils-19690?q=coil

-

New Find.70 240Z

I've always thought of you as a 280ZX guy. That has to change now. #6920 is pretty low. Better leave the dust/patina on it in case you decide to sell.

-

HLS30-07848

Never mind. 2012 isn't that long ago.

-

HLS30-07848

Spray the carb with soapy water, blow in the port, and see where the bubbles happen. Or put a hose on the port so that you can get your ear in the right place to hear a hiss when you blow in it.