Everything posted by Zed Head

-

Failed CO emissions - all controls removed - where to start?

The numbers aren't really that bad. It only takes a few misfires to blow them up, you're actually within simple tuning range, i think. Are you sure it's not a 79 280ZX? The emissions guys might have used the build date as the model year. The AFM to manifold hose looks more ZXey than Z. Not sure. There should be a sticker on the door jamb or under the hood that says "CATALYST" if it had a converter. Look for that. Did the visual inspection include the EGR parts? How do you know the gas cap failed, do they test that? Lucky for you guys though, new caps are available for the unleaded style filler necks. Find them on the internet. The PCV system has been disconnected also, which tends to dirty up the oil with gasoline vapors and combustion byproducts. You can reconnect it. It has a lot of the "get rid of emissions junk" mods done that cause problems for people.

-

Coolant in the oil.

Check the front cover carefully. It has coolant on one side and oil on the other. A crack or hole could cause your problem. Also, check the thermostat housing and its bolts. One of the bolt holes is a through-hole in to the cover, behind the chain guide. Many timing chain guides have scars on the back side from using a too-long bolt in the T-stat housing.

-

Patton Machine Fuel Injection

Have you tried the crude but effective "fuel pressure gauge hanging out of the hood" method. Real-time pressure readings will tell you if the filter is clogged.

-

Engine Burning Oil

Compensator would be a better word for it.

-

Sticky idle

You're not justifying your statement. Explain why. You're asking questions because you don't know then correcting people like you're an expert. Explain how your finger moving the throttle blade is different from the spring moving the throttle blade. You shut the blade with your finger, a stronger spring could do the same. Sorry, but you shouldn't comment on people's attitudes. Calling someone cranky just leads to more crankiness.

-

Sticky idle

No offense. But there's no target to shoot at... Your posts are full of distracting information, then you say "I already checked that" when people make suggestions. "Please understand"? You came here asking... Seems like you're trying to make sure that only you find the solution. Good luck.

- Sticky idle

- Sticky idle

- Sticky idle

-

Sticky idle

So, actually two of them are sticking. One thing that happens when the throttle blade is partially open is that any ported vacuum holes will open up. They are typically right under the edge of the blade, Blocked when the blade is closed, pulling vacuum when the blade is open. Usually they are meant to actuate some other valve, and not have any actual flow through them. Just supply vacuum, no flow. It might be that you have the ported vacuum ports open to atmosphere and the blade balance gets screwed up because of it when the blade is partially open. Short - check your ported vacuum ports and see if they're open when they should be sealed to a separate device. I don't even know if those carbs have ported vacuum ports but most do, since that is how ignition vacuum advance is often controlled. It might be labeled as "ignition vacuum advance port" on a diagram. Edit - also, if they are connected to the distributor vacuum device the advance diaphragm might be blown, allowing a leak.

-

Sticky idle

I confess, I didn't watch the videos and didn't really absorb everything you wrote. Certain types of videos don't play well at all on my old computer and I didn't want to download it. A youtube link is better, youtube videos play well for whatever reason. Plus the videos are too close focused they should show all three carbs at the same time, and the angled view is not pleasant. No offense, they're just not good movies. 25% Rotten Tomatoes.. But, like jonbill said, it seems like a simple extra or stronger spring, maybe on just the sticking center carb, would do the job. Why make it more complex? I think that CO has pondered how the vacuum effects the backside of the blades, top versus bottom halves, if I remember right. A sticking EFI throttle blade. Same concept. He might have some thoughts. @Captain Obvious

-

Looking for original block

Put the block number and type of block in your title. And post a picture of one, as example, so people know where to look. Many people aren't aware that the engine's have a serial number. Edit - I meant post a picture of the serial number on the block.

-

Sticky idle

No offense intended to the guys with the problem but buying a new manifold to fix a linkage problem makes little sense. There are three throttle blades and linkage to make them work together. If the blades aren't sticking it's the linkage. If a new manifold works it's because it came with new linkage.

-

fuel rail and pressure regulator suggestions-78 280Z

And...if you really want to go an extra step for reliability, get an aluminum fuel rail. These engines typically have heat soak/hot start problems and that is one thing that seems to really help the problem. Very little worse than getting in to your car after 20 minutes in the store, with people watching and wondering about the cool little sports car, just to sit there for 30 seconds that seem like 30 minutes while the engine coughs and pukes until things cool down.

-

fuel rail and pressure regulator suggestions-78 280Z

Most of the adjustable regulators lost pressure rapidly after shutdown. It's very annoying, people spend hours diagnosing hard start problems and end up replacing their regulators to one that doesn't leak down. If you find that you need more fuel to the injectors it's better to add resistance to the coolant temperature sensor circuit. Short - a good OEM style regulator will probably work best. While you're on it though, replace all of the rubber fuel hose, especially the high pressure side. Even back at the fuel pump. They dry up and crack and split longitudinally and will probably leak. Plus they're not designed for ethanol fuel.

-

Sticky idle

That tells you that the binding is at the throttle linage on the manifold, not at the cable or the pedal. You can extend the the thought process and push on the linkage with your finger. Open the hood and poke around and you'll probably realize something. Your picture shows that you have quite a bit of slack in your cable. Seems like a good tune of the overall system might help. Lots of adjustable bits there.

- Sticky idle

-

Desperate Need: 240Z R180 Rear Axle Flange

What is torn up about it? Do you think the cap won't fit correctly? If it's solid in the hole, the clip fits the cap on the inside. The outside of the yoke can be pretty ugly with no ill effect. It's the inside surface that really matters. I think that Terrapin Z might have some but he is in Washington state. Pretty sure that the R200 halfshaft parts will work fine also, doesn't need to be from an R180. @Terrapin Z

-

Engine Burning Oil

I have to commend your initiative in just diving in and taking action. Obviously you know a lot about how things work. I've found myself well down a path I wondered about taking before. If it happens again at least you'll know what it's not. Maybe.

-

Old rear brake conversion repair, NEED HELP!

Get on to Rockauto and browse. They have lots of pictures, you might see a critical clue. https://www.rockauto.com/en/catalog/nissan,1990,240sx,2.4l+l4,1208977,brake+&+wheel+hub,caliper,1704 https://www.rockauto.com/en/catalog/nissan,1985,maxima,3.0l+v6,1211252,brake+&+wheel+hub,caliper,1704

-

Old rear brake conversion repair, NEED HELP!

You're asking people to interpret your memories and compare to their memories.. A picture might be better.

-

75 280Z won't run.

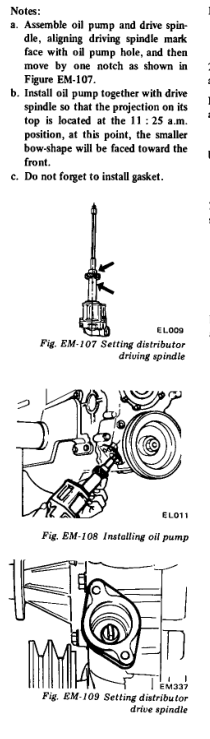

I just noticed that the FSM never really says to have the timing mark at zero when installing the oil pump. It must be assumed that things are done directly after installing the timing chain. No wonder so many people have problems. They left out the most important part, for people doing only the oil pump work.

-

75 280Z won't run.

Your timing mark is the crankshaft position. You installed the oil pump gear in the wrong position. Best to take the oil pump back off and reinstall it and the distributor drive quill correctly.

-

'78 280z Running Lean?, lack of power

What was the measured fuel pressure when the problem happened? Does the engine have EGR? It's hard to solve problems with the EFI system unless you're very methodical, or lucky.

-

Removing 280z tail housing

How about drilling the other end of the pin, threading it, and using a slide hammer?