Everything posted by zKars

-

low oil pressure

Just to put it out there plainly, the block threads are 1/8 BSPT. The adapter needed is the one SteveJ linked to, BSPT male into the block, 1/8 NPT female to thread in common gauge fittings.

-

Thermostatic Valve needed...any idea where to get one?

Seven years. OMG. Yes I still have some.

-

Vintage Connections Prices Increasing

I’ll do the same. Thanks for the reminder.

-

Brakes rubbing after remounting wheels

You lowered the car too much. Does it rub when you turn? Or turn and going over bumps? Stop, turn the wheels full left and get out and look what’s close to what.

-

'69 through '73 Steering Wheels - Wood, or Plastic?

So: If I may be so bold as to offer a final summation: Made of wood? No. Made with wood? Yes Looks like wood? Yes to most, no for some, but it is one of the basic design design objectives of this damn thing, so Yes is reasonably correct. Which wood? Who cares. As long as it makes most drivers think “wood”. Feels like wood? Doesn’t matter. Original question is “wood yes or no”. See above. Made of plastic? No Made with plastic? Yes Feels like plastic? See above.

-

Rebuilding R160 and/R180. Tip for bearing replacement.

On to that really nasty race that on the inside of the pinion shaft. Getting it out is easy, but getting it lined up and beaten back into place from the nose is a real test of wills. It’s down there about 10 inches…..

-

Rebuilding R160 and/R180. Tip for bearing replacement.

Clamped it in the vice upright, got the MAP gas torch out (propane would be just fine) and warmed up the outer circumference for about 90 seconds. The race just popped out with minimal prying with a flat blade behind it. 5 minutes, both sides done. Bamn!

-

Rebuilding R160 and/R180. Tip for bearing replacement.

The other day I was tearing into a Subie R160 CLSD that had sustained some rust damage and thought I’d better replace the bearings. When I got to the races in the outer side covers I began my usual anxiety cycle where I think of 11 ways to get them out, but all are risky and start doubting if I can figure it out. The dang covers are aluminum and the races are stell, so there is no bangin’ or rippin’ allowed. There is no place to just punch them out, the thick edge you have to apply force to is well shrouded. An internal bearing puller might work but you have to rig up a plate to bolt the hole thing to. Bah After about an hour of going back and forth with ideas, each one more extreme and time consuming than the last, BANG the right way leaped into my heat. Heat. Aluminum expands like crazy compared to steel.

-

air filter source

Glad you found one. Getting a bit tricky to source. There is a K&N Filter for the 240 as well. E2910 I believe. I’m no great fan of the K&N filter, but this particular filter body is rubber and a tad thicker than stock, so if your housing is lacking the thin stock rubber strips that seal against usual OEM steel filter, these would be ideal.

-

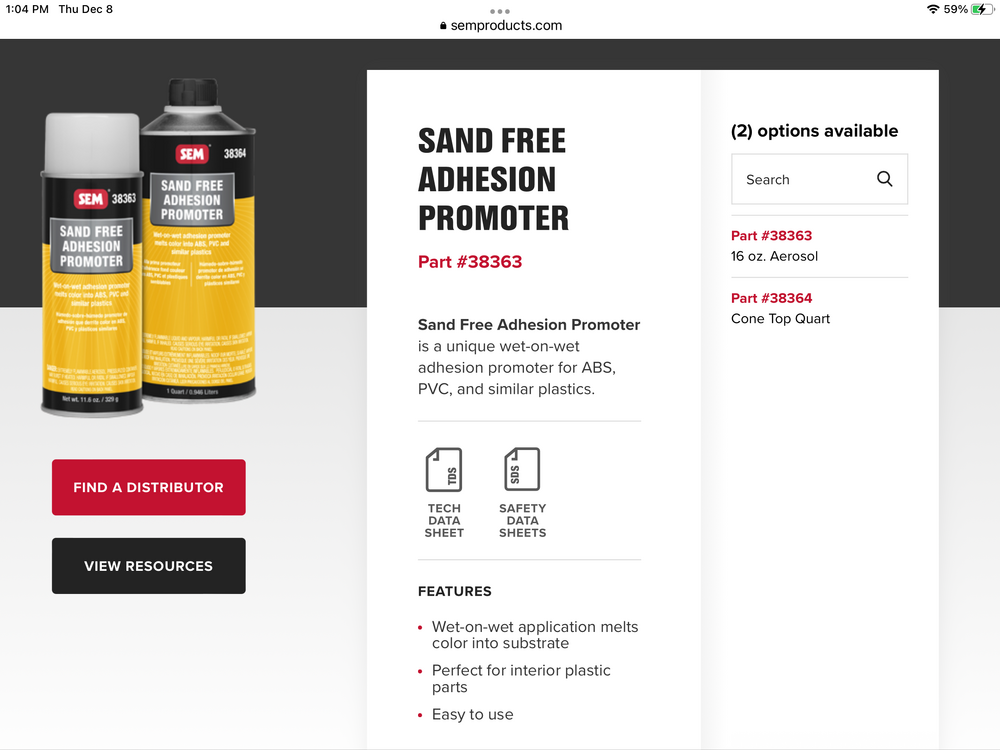

280z Interior Plastic Repair and SEM coat

Don’t interchange the vinyl and plastic preps. They are different. You’re welcome

-

280z Interior Plastic Repair and SEM coat

Done plenty of all of this. SEM Plastic Prep (not vinyl prep) works wonderfully, It’s primary job is to clean and degrease to remove traces of everything un-desirable. Then use an adhesion promoter like SEM 39863 JUST before spraying the top coat. This softens the plastic and let the top coat stick. Franky anything that will thoroughly degrease the plastic and clean it without leaving any residue will work. I’ve recently been using generic body shop degreaser to clean, even Spray 9, anything powerful and degreaser-y. Then Adhesion promoter, THEN top coat. The Sand Free product sounds like a newer development for coloring plastics. I haven’t used it, but the description sounds interesting. PLASTICS only. Vinyl and leather dying is different. The Vinyl preps typically clean and degrease and do the adhesion promotion all at once. Filthy vinyl, use spray 9 and a scrub brush and water rinse, THEN vinyl prep just before top coat. Cannot stress enough the need to clean the plastic or vinyl extremely well. None of the top coats stick to 30 years of sweat, body oil and Armor-All worth a damn. Big surprise. I’ve even used Scotch brite pads to scrub to get whatever off da plastic first. Hope that helps

-

what happens when safety comes last...

My entire head, face and upper body were subjected to a huge flood of ATF that came out of at least two plug holes on an engine that had been literally FILLED with ATF as I attempted to crank it over. It was as if the engine had been filled to overflowing with ATF with 2-3 gallons worth to preserve it I suppose. The engine did eventually start, and I discovered that of course the exhaust was also filled with ATF and the initial start up caused a huge soggy mess of mouse nest and ATF to be ejected out the exhaust and directly onto the side of my Ford F150 that was parked across the open garage door. That Z smokes for weeks afterwards as the ATF eventually burned off. I have a picture somewhere

-

Taking Apart 240Z Spring Loaded Seat Hinge

Well I’ll be horn swaggled….. All the invented drama for nothin’ Been watching too much reality TV apparently. When seat back is all the way forward, no tension. Nothing happens until you start pushing it backward. Duh…. I’m going to go take some apart just to laugh at them….

-

Taking Apart 240Z Spring Loaded Seat Hinge

Right! The cotter pin! With that it will be easy. Bolt it to the bench, put an extension on the arm of some kind, pull the cotter and pin, and un-wind it. Easy peasy. Make sure your life insurance in paid up first…..

-

Taking Apart 240Z Spring Loaded Seat Hinge

Clearly these hinges were never intended to be disassembled, all fittings are permanent rivets and spot welds. If I had to disassemble it, I would bolt the seat bottom section to a solid surface (work bench) and bolt a long strong extension to the seat back bracket (like two feet) to give me leverage on that spring when I did grind off the welds or pin heads so I’d have a prayer of holding it back. Then I could hold that long lever and slowly unwind it. Do the reverse to assemble. I would also try to convince someone I don’t like to do it for me…. Or just sand blast what is visible and paint it grease it and be happy……

-

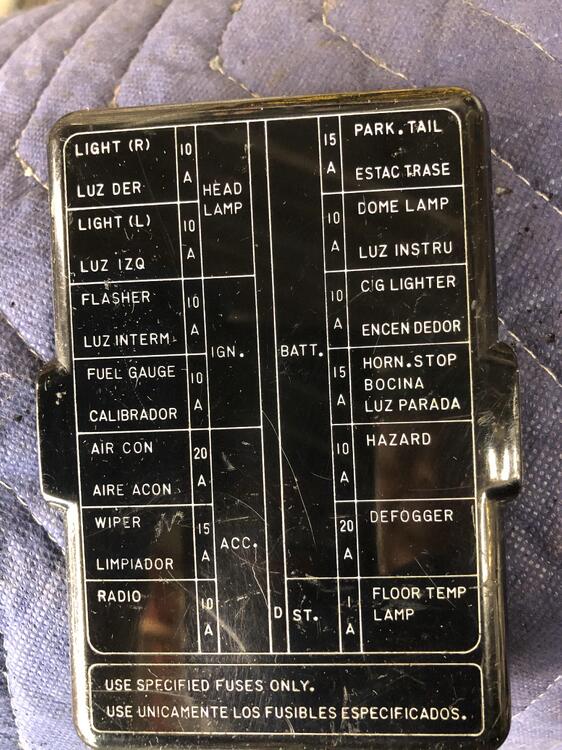

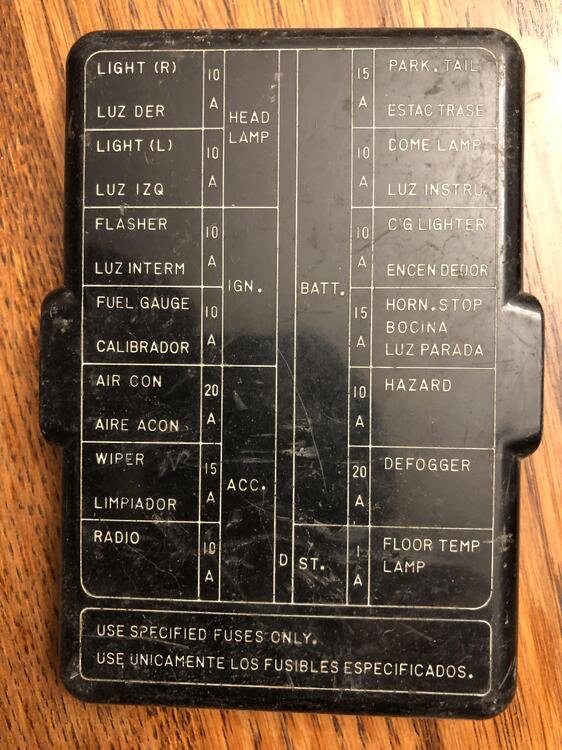

Parts Wanted: 1977 280z Fuse Block Cover

$10+postage. Send me a PM and we’ll conclude the deal offline.

-

Coolant leak near carbs

That is the block drain. The plug or whatever in the picture is not the stock one, who knows what someone used in the past. Remove whatever is there (it will drain 99% of the coolant so be prepared, drain the rad first) and see what you have. That hole is 1/2” BSPT threads. In this case, since NPT is the same thread per inch as BSPT (14), you may get a 1/2 NPT plug to fit and seal if you have trouble sourcing a 1/2” BSPT plug. 1/2” NPT on the left, correct block plug with 1/2” BSPT on the right.

-

Parts Wanted: 1977 280z Fuse Block Cover

-

Parts Wanted: 1977 280z Fuse Block Cover

Being a thing that exists down in the passenger foot well, it is subject to abrasion. I will take the plastic polish to it and see what comes out/off and repost a picture.

-

Parts Wanted: 1977 280z Fuse Block Cover

-

1981 280zx 5 speed

And for the sake of completeness, today I’m rebuilding a later 5 speed that DOES have the reverse lockout switch access, so I took a few pictures to show how to get that shift rod pin out. No trick necessary, just take the reverse lockout (don’t break a bolt like I did, grr….), position the lock pin so you can see it and get a straight shot at it through that hole, get your air chisel out, put the nut back on the bolt (about 2/3rds of the nut thickness) so the tip of the air chisel has a place to set, then pull the trigger for maybe 1/2 a second. Boom it’s out. Remember you can’t put the reverse lockout thingy in the wrong way, the holes are offset. Another detail, the o-ring on the reverse lockout thingy, and on the end of the shift rod, and the one on the outside of the speedo cable drive cog are all the same.

-

71 series 2 console

I can offer this perspective about what is the right console for your car. Since the various welded on brackets that mount the early and late consoles are different, both at the front and rear of the console, whichever ones you have on this Z determine which console is correct. You mentioned the early one you have “fits” assuming the screws that secure it under the ashtray cover in the front, and the three in the rear all fit, then your car is correct with the early console. Changing to the later console is not trivial, but possible. I have seen plenty of Z’s that are a mix of various so called S1 and S2 parts in this VIN range. You have the S2 steering wheel, S1 console. Your air vents are likely on the sail panels, but you may still have vertical defroster lines. Rejoice in the quirkiness of the mixed up car. It’s a real thing.

-

Z's on BAT and other places collection

I’ve had me dirty little fingers in this lovely pile of 73 chocolaty goodness. The paint is the best over all quality I’ve seen to date. The car is an amazing low mileage time capsule. It certainly is raising some mighty good numbers isn’t it? Couple of heavy hitters doing a bit of sparring, will have to wait until the weekend to see where it finishs.

-

1981 280zx 5 speed

- 1981 280zx 5 speed

You can move the rod in and out several inches so the front to back position is not very critical. I made a simple plate jig to hold the end of the rod in place to support it while bashing the pin out. 17/32 bit for the rod I think. Hose clamp to hold the rod fully forward. This puts the pin head exactly 3-1/8 back from the case face. I have used an air chisel tool with a round bit in the past to get this pin out, it works extremely well and is nearly instantaneous. Beating it with a punch requires more effort and unpleasant words. - 1981 280zx 5 speed

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.

Subscriber

Subscriber