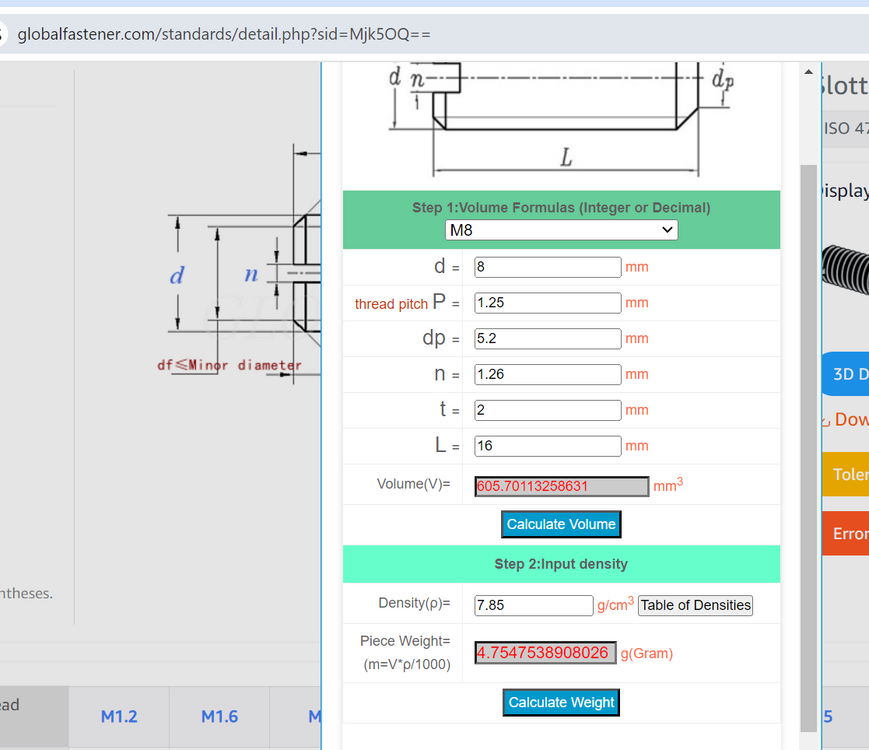

My last incarnation was a 4 gram brass piece threaded into the side of the float. This seemed to work well:

And as for position, I put it into the side of the float over by the hinge pin. That way, it it ever started to unthread, it would tend to hold the float up, not hold the float down. My thinking is it's safer for the float to be held up (thereby cutting off the flow of fuel), than it is for the float to be held down (allowing fuel to flow even when it shouldn't). "Fail-safe".

You could probably find something generic to use instead of making a custom piece. Maybe a brass wood screw of similar mass?

And as for your hinge integrity, I think maybe yours looks fine. Maybe bent down a couple thousandths, but not enough to worry about.

Subscriber

Subscriber 3Points1,282Posts

3Points1,282Posts