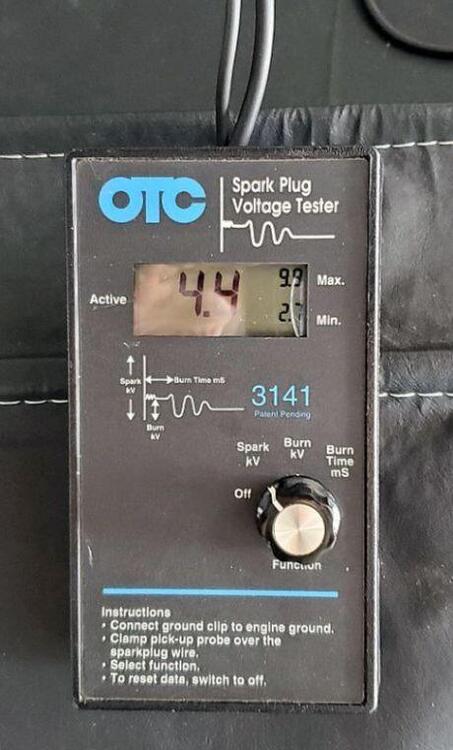

It is critical to get the setting of torque on the front pinion nut right. When you put the flange and nut back on, do not just torque it to the factory setting and be done with it. Look for information in factory documentation regarding what torque setting to use when reusing all of the bearings on the pinion gear. it is a different (lower) specification than when replacing the bearings.

I recommend pulling the carrier out of the case before installing the flange and the pinion nut. Then use the low end of the torque specification. After setting to the low end of the torque specification, check the amount of turning torque required to turn the pinion shaft - you are checking pinion shaft turning resistance at this point.

There is a factory manual uploaded to the resources section of the forum. You need to get the turning resistance to be close to correct specification.

If you don't do as outlined above, you are taking too big a chance at setting too high a pre load on the bearing stack on the pinion shaft. The weak link is the pinion bearing - the front most bearing. However, with a damaged pinion bearing, it only takes a low number of miles to damage the ring and crown gears also.

Garrett

Subscriber

Subscriber 4Points1,282Posts

4Points1,282Posts

.thumb.jpg.5b607f787f0162374b5c384bbe045e3d.jpg)