Thanks! I will work on the dog leg areas first and then see where I land with door gaps. I don't think it would be much work to stitch some metal on the few inches of the bottom, front edge of the door, but it will likely cause at least a little distortion. May leave it alone.

I didn't want to take off the lower corner of the driver quarter panel - I just kept looking at it and trying to convince myself it wasn't worth the extra effort. I examined it closely and contemplated... Car is upside down in these pics.

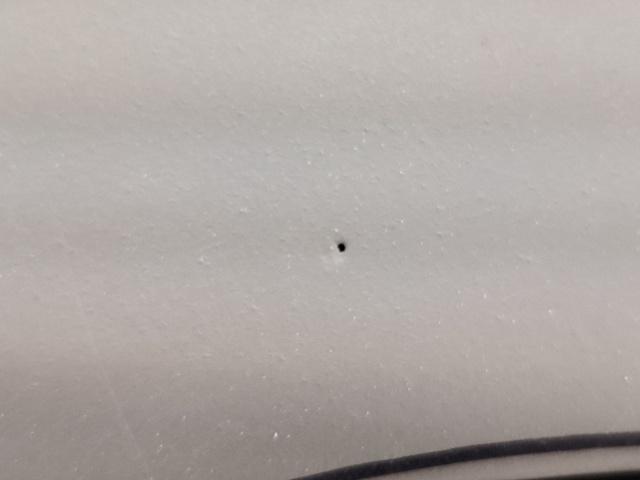

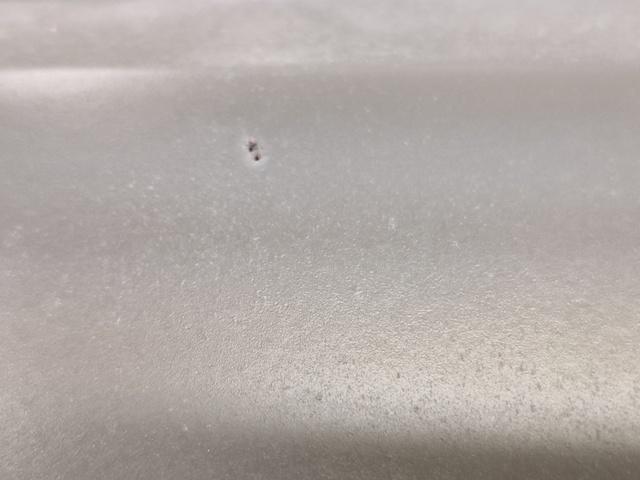

In the first pic, I am looking at distortion in the area where the quarter panel spot welds to the rocker. These outward points or "dents" are areas where the metal is super thin and being pushed outward by the expansion caused by corrosion.

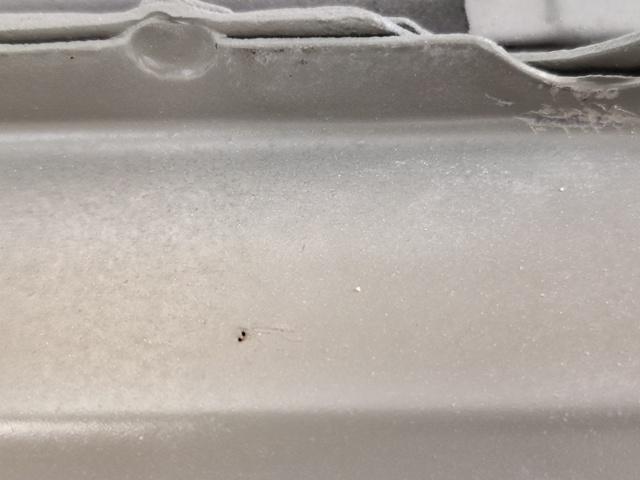

Seeing these little pin holes all the way through the metal, I know that the corrosion on the other side is substantial enough to be breaking through. Especially, on the bottom flat area, any surface repair here would be short lived if water gets in again.

Because I want to cut and modify the dog leg curve to improve the fit with the bottom corner of the door, I went ahead marked out where to cut and started cutting and drilling out spot welds. Opening up the panel revealed quite the mess:

Unlike the passenger side, the corrosion on this side damaged some of the other, inner panels.

Once again, I employed the sandblaster to remove the rust.

For this side, the panels are more damaged, lots of holes in the back of the rocker panel and a few holes in the inner wheel well panel:

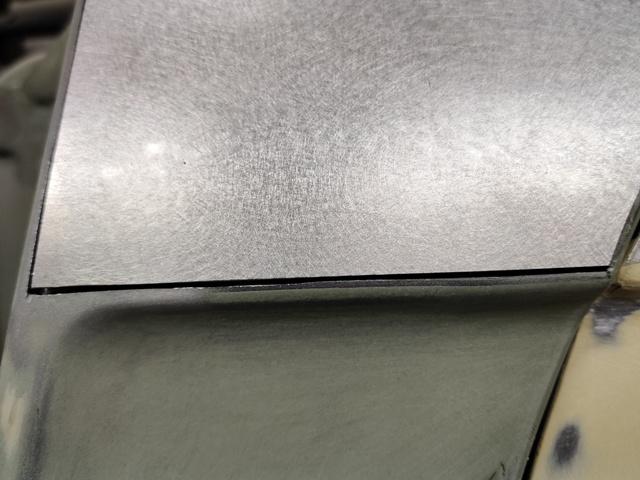

Using the old panel as a guide, I cut a new panel from a flat sheet, and used some 1" X 1" square tubes and my vise to make the 90 degree bend for the weld flange. Then I marked off a line locating the ~ 45 degree bend and used a piece of aluminum channel (it has a really sharp corner) to replicate the factory bend radius. Some hand bending of the rest of the panel (clamping the panel in between a 2 X 4 and my bench surface) to make several slight bends... to replicate the shallow curve...) Getting the distance correct between the 90 degree and 45 degree bends is the hard part. I am happy with this:

Once in the correct shape, I used the old one again as a template to locate holes to match the spot weld cut outs. Then I used a 4 1/2" grinder with a flap wheel to sand the edges of the panel to fit the opening on the car.

Even with just one vise grip holding it on, the fit is very close.

I am very happy with how this turned out. However, I can't close it up yet, as I have more sheet metal work to do to fix the inner panels.

Subscriber

Subscriber 4Points1,282Posts

4Points1,282Posts