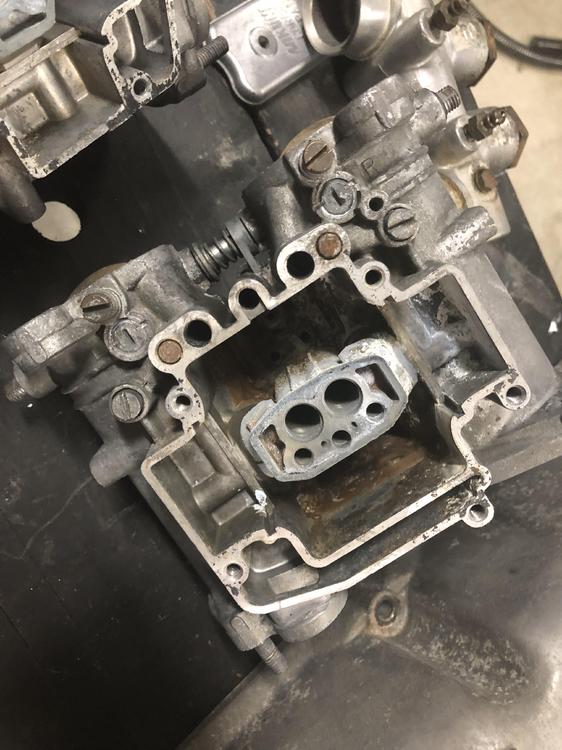

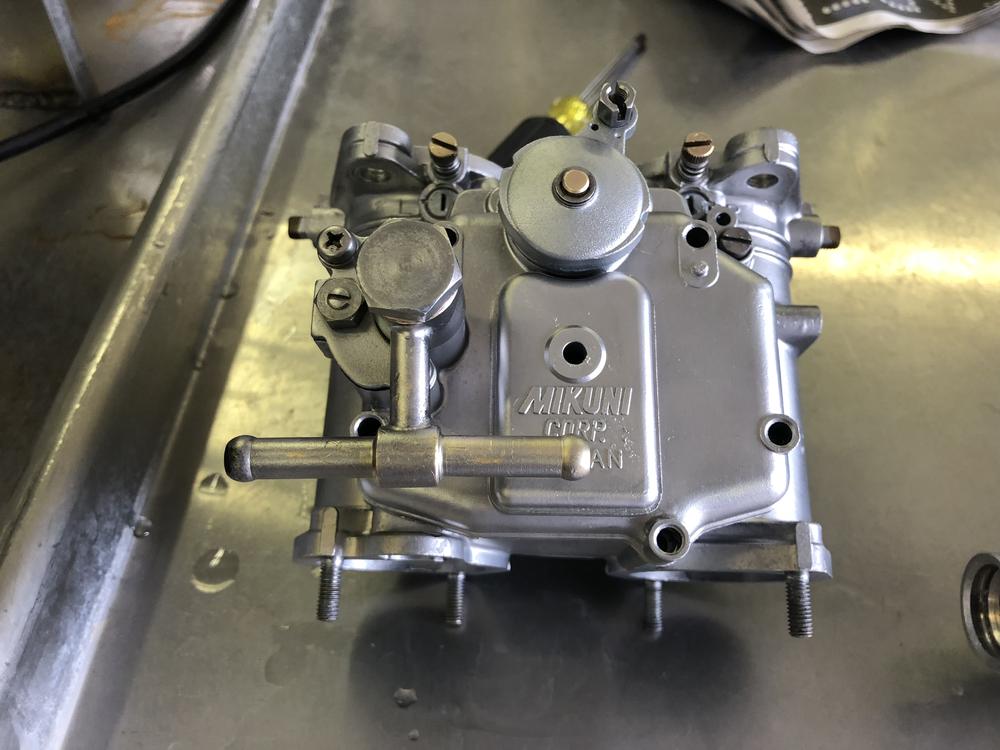

So what about this ten turns down thing? What's that all about? The ten turns down method is an alternate method of checking the fuel level instead of using a clear tube. Brian claims to have taken some measurements with a straight edge and believes he has determined (unconfirmed by me) that when the fuel level in the bowl is 23 mm down from the inside of the lid, then it should also be 1 cm down from the top of the nozzle when the nozzle is adjusted all the way up (zero turns down).

He also contends that this might be not only more convenient a measurement technique, but more accurate. That's what he was alluding to when he says this: "HOWEVER: Even though adjusting the floatbowl levels to 23mm down is a factory setting, it doesn't guarantee that the fuel levels in the carbs are the same."

What he's saying is that even if you have set the fuel level in the bowl to be 23 mm down from the inside of the lid, it doesn't guarantee that the level will be in the correct level at the nozzle. The REAL important level is where the fuel is inside the carb, not inside the bowl chamber. So if there is something wrong with the bowl mounting or the bolt holding the bowl to the carb is bent or something, you could have the level in the bowl "to spec", and still have the level wrong inside the carb body.

So to combat that, he's suggesting that it may actually be even better to directly measure the level inside the CARB instead because that's what's really important in the end.

And to do that, he believes the correct level INSIDE THE CARB is 1 cm down from the top of the fully raised nozzle. Doing the math using the pitch of the nozzle adjustment nut and all that yields the following:

A FUEL LEVEL IN THE CARB THAT IS TEN TURNS DOWN OF THE NOZZLE, SHOULD BE THE CORRECT FUEL LEVEL AND SHOULD ALSO CORRESPOND TO APPROXIMATELY 23 MM DOWN FROM INSIDE THE BOWL LID.

Finally, after you have used the ten turns down method the check the fuel level, you should put the nozzle level back to it's ballpark setting of 2 1/2 turns down. His not mentioning that is clearly a simple oversight. Check the level ten turns down, and then put the nozzles back where they belong when you're done.

Subscriber

Subscriber 1Points3Posts

1Points3Posts