From Fred Puhn's book, 'How to Make Your Car Handle':

"Many elusive twitches and wiggles can be blamed on bump steer, and often it is the cause of high-speed stability problems [Hello, 240-Z!]... Try really hard for zero bump steer at the front. A car with bump steer in the front suspension will be unpredictable in a turn and unstable during braking. The car is very sensitive to toe-in changes. With bump steer, toe changes can happen with every dip in the road or when you hit the brakes. Both toe-in and toe-out errors give terrible handling and should be avoided in the front suspension".

The basic goal: On each side of the car, keep the tie rod parallel with the lower suspension arm throughout the arm's full travel (or, if not, at least for all but the last inch of droop and/or compression).

Bump steer's evil twin is something called Roll Steer. It's the same thing, but experienced during cornering. From a design point of view, you still want zero roll steer and bump steer at the front. Roll steer seems to be of greatest interest at the rear. For cars with IRS, the goal is to use roll steer to encourage understeer when the roll angle becomes extreme.

To relieve bump steer at the front of the car, one solution is to raise or lower the steering rack (which changes the angle of the tie rods). In your case, though, this has become a problem rather than a solution, so you need to work with the other fixes to try to un-do the result.

One of the alternative fixes consists of bump-steer spacers. You've tried these and experienced a positive (but incomplete) result. Maybe you could fab additional spacers using your new/old lathe?

Another fix is precisely the type of spherical rod-end tie rod set-up that Chas has illustrated. Puhn says, "This allows shims to be used between the steering arm and the tie rod end for small bump-steer adjustments. Large changes cannot be made this way, but it is a good way of getting an extremely precise small adjustment." Hmmm. Maybe not enough to solve your situation?

Interestingly, Puhn's book talks about yet another technique for alleviating bump steer and uses a Datsun 510 to illustrate the point. It consists of bending the steering arms. Puhn cautions that this is a job best left to specialists because: 1) you may crack the arm casting if you heat/bend incorrectly, and; 2) the arms will need to be crack-checked and then heat treated afterwards.

I wonder if a less painful way for reaching your final goal would be to use a suspension geometry algorithm (I guess they're called 'apps' now) to investigate different combinations and settings before you actually do any more tweaking/cutting/welding/bending (and purchasing). There's got to be an on-line, free-for-use app on a racers' site somewhere. Maybe one of the other CZCC members can help out with this so that you don't have to go searching (and if you find one, please let the rest of us know so that we can play with it too ).

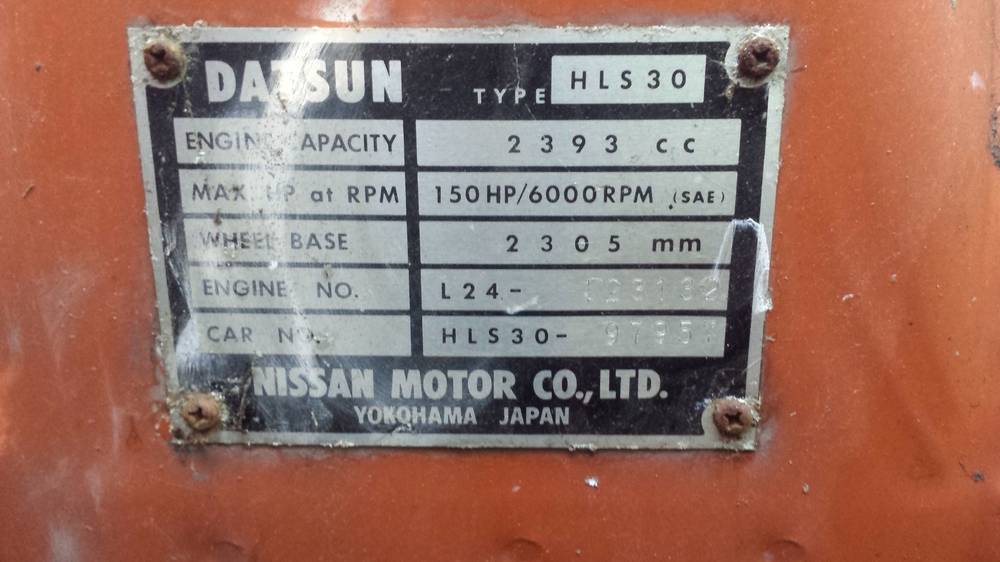

Among other things, it would be interesting to see whether the stock Nissan set-up really does achieve zero bump steer over the full suspension travel (unless somebody else has already investigated this?)