No, it's not about driving up a steep hill at 20mph in 4th gear ...

It's about replacement lug nuts for the authentic Libre wheels on Zup's immaculate silver 73 240z.

In looking at his car, my eye was always drawn to the deteriorating condition lug nuts on the wheels. I became determined to find a quality set for him that would do justice to such a nice car. I quickly found that it is not so easy to source the correct lug nuts for those lug centric wheels. The standard M12 x 1.25 spec is no problem but in the correct shank & washer style with the all important shank length is difficult.

I found a quality set of Mcgard tuff nuts that met all the specs except for the shank length being too long, they would bottom out against the hub before the wheel was seated and tightened. The solution it seemed, was to machine the shank length of the nuts down to the optimum length for the wheels. It then became obvious to me that the answer was to recruit the assistance of a highly skilled forum member ..... Captain Obvious.

After discussing the details of the secret project with him, he very generously agreed to assist with machining the new Mcgard nuts to Libre specs. I ordered & shipped the new nuts to him and in the meantime, made careful measurements of Zup's Libre wheels to determine optimum length. The end result we agreed upon was .460 effective shank length after the washer is installed. The Captain completed one set & shipped it to me for test & verification of fitment. They were perfect and so was the quality of his lathe work!

The final 4 completed sets were delivered Saturday, I drove up to his house & presented them to him, we did the final installation, and he was extremely happy with the results.

A very big thanks thanks to you Bruce for making this Obvious / Driver joint project possible. He was very busy working on a complete top end job with his son's new Subaru but still took the time to work on the nuts.

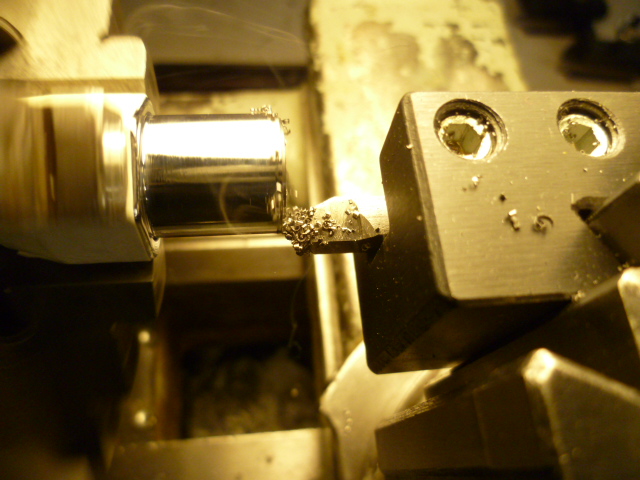

Nut in the chuck

Original vs Machined End view

Captain's lathe at work Zup's Ok Job done Inspector # K9 gives final approval ...