All Activity

- Past hour

- Series I is more hesitant to Start

- Today

-

darom started following rear clunking noise '76 280z

-

rear clunking noise '76 280z

Hi guys, I am chasing a rear clunk noise which happens when going over the road cracks and potholes. Pushing the rear of the car with hands in an up/down motion doesn't reproduce it. I replaced all the bushings in the rear 10 years ago. I probably put about 1000 miles on the car. First, I thought the noise was due to my read speaker deck, I removed it. Another thought was the deck lid, there is small play in the deck struts due to the loose bushing/pin attaching the struts to the mounting location. I jacked up the car, removed the strut assemblies and checked the rear strut insulators. They are solidly attached, no play. However, I saw a hairline crack on the LH side. I checked all the rear sway bar bolts, nuts, plus the R200 hardware, rear half-shafts bolts/nuts, fuel tank/pump, mustache bar hardware. 10 years ago I installed an aftermarket RT mount, there is a 1/8 in gap between the R200 and the RT poly bushing when the car is rested on the jack stands. What are your thoughts? I went through a lot of posts about the rear end clunking (hundreds of hits lol), and I think I checked all of them on my car with the exception of that hairline crack in the insulator. I am planning to order a pair of strut insulators to begin with (240z ones with an adapter, unless someone has a pair of later 280z ones in a good condition?). Thanks!

- Series I is more hesitant to Start

-

dutchzcarguy started following Engine rough running - at wits end

-

Engine rough running - at wits end

Zed, i've seen it in my 280ZX serv.man. ! It says something like if you get the tank completely empty you have to fill it for at least 2/3 !! The pump will otherwise not prime! (I often get the impression that you people don't read your service manuals.. except Zed ofcourse..) It seems to have to do with communicating vessels.. so to be sure it works i have 50 ltr of fuel standing with my car as the fueltank is empty at the moment (280zx).

-

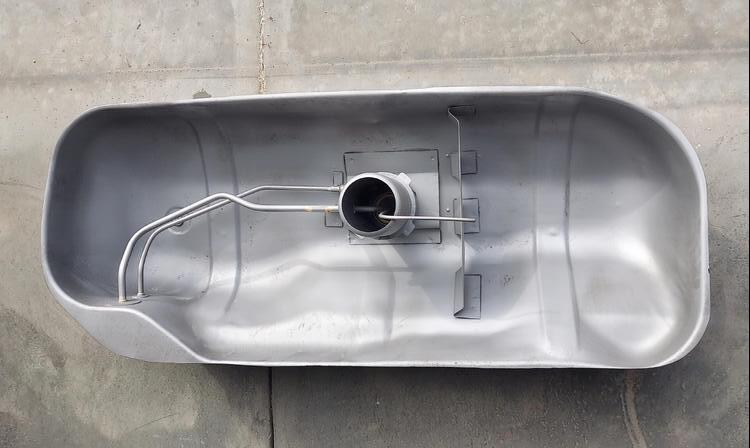

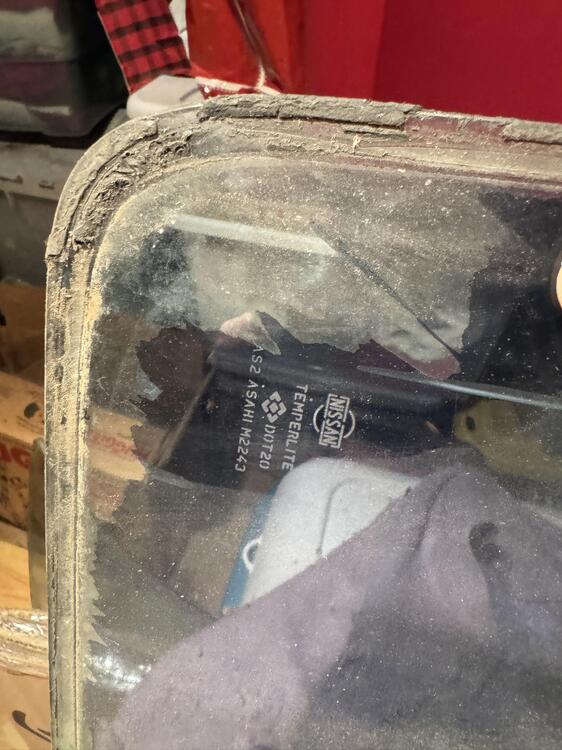

EFI Fuel Tank Restoration

I didn't trust my ability to hermetically weld the tank. So I assisted a friend while he tacked it together. He then took it to a mutual friend with a TIG welder and finished it up. At this point, I poured more Red Kote into the tank and allowed it to flow over all of the seam. I let this sit for about a month to cure. Then, I sealed off all of the openings and blasted off the remainder of the external paint. Interestingly, there were dozens of small hidden rust spots beneath the paint. You couldn't see them through the paint. But when the media hit it, the paint would flake off, revealing a brown rusted spot. After blasting, ready for paint. I primed and painted it with Rust-oleum automotive paint in rattle cans. It turned out decent. No one will be looking at it. Note I didn't remove the original rubber blocks. They were stuck on really well, and not damaged. I did remove the original foam rubber piece near the sender hole because it was falling apart. I replaced it with a similarly-sized piece of 1/8" (3mm) thick EPDM rubber, just to make sure nothing would rattle. You can also see where I masked off the factory marking, just in case anyone might ever care if the tank was original. Lastly, I leak tested it by putting a few gallons of gasoline in it and allowing it to sit on each edge for 30 minutes. The sun was out, so the tank heated up and pressurized, which was a good sign. I'm happy to report that I've reinstalled the tank in the car, and it works fine. No leaks. And no more plastic gas can bugeed to the rear shelf.

-

EFI Fuel Tank Restoration

Now for the rust-preventative coating. I knew that if I hand-coated the parts, I'd have to leave an uncoated area near the seam for welding, and then slosh more coating in the tank afterward to cover the seam. I reached out to the manufacturers of several tank coatings. Knowing I would end up with two layers of coating in parts of the tank, I asked for their recommendations. Most advised against it. One supplier, Red Kote, specifically says in its literature that it can be recoated. A phone call confirmed that it would be fine. So that's what I used. I used a brush to coat the halves, leaving bare metal where they would be welded together. The stuff is thick, like molasses, and thickens in minutes. So I had to work quickly to get an even coating. Then we could reinstall the pickup tube (also coated), minus the screen. I made a sleeve from a scrap of stainless tubing and got a friend to braise it together. Then I tackled welded the top half of the canister back on. I touched up each joint after allowing it to cool and giving it a good cleaning. Red Kote smells and acts like PVC pipe cement. It puts off some serious fumes. Acetone is the recommended solvent for thinning it. So I used that to clean each surface immediately before coating.

-

EFI Fuel Tank Restoration

With the majority of it cleaned up, I tackled the screen. I drilled out the spot welds to separate the canister and cut the suction pipe to remove the screen. The screen was almost completely clogged with fine particles of rust. No wonder fuel wasn't getting out. I carefully cut the screen out. You can see the small pile of debris that was stuck inside the screen. The screen itself was so fine it felt like linen.

-

EFI Fuel Tank Restoration

Ultimately I gave up on chemical rust removal. For one thing, it didn't fully remove the rust. And as you can see, unless i built a tank and fully submerged the parts, there were sections of baffle that couldn't be treated. I tried soaking rags and other things. But I wasn't happy with the result. Lastly, I read that the coating I chose would adhere better if there was some surface roughness. So I bead blasted the tank halves.

-

EFI Fuel Tank Restoration

I ended up using a product called Rust911 to attempt to chemically remove the rust. It comes as a concentrated liquid that you add to distilled water to make a chelating solution like Evap-O-Rust. At $95 for enough to make 16 gallons, it was a little more cost effective. During: After Not perfect. But it removed most of it. FWIW, it appears to be just as effective as Evap-O-Rust at about 1/4 the cost when you factor in buying the distilled water.

- Yesterday

-

Engine rough running - at wits end

Huge thanks to Charles for coming over and helping me get the tank back in. It feels indescribably good for her to run under her own power with a complete fuel system. I'll circle back to my fuel tank restoration thread with an update. But in brief: cut tank open, bead blast clean, drill spot welds for screen canister, cut suction pipe to access screen, remove screen, Red Kote everything, reassemble, slosh more Red Kote around seam, bead blast outside, paint. Easy, lol. Tank restoration thread: https://www.classiczcars.com/forums/topic/68742-efi-fuel-tank-restoration/?&_rid=30865

-

Engine rough running - at wits end

So we worked on the 280z some more yesterday. Put the restored tank back in it and added some fuel. Fuel pressure came up after cranking but wouldn't come up in the "On" position. Cranked up first time. Bolted some wheels on and went for a quick spin!! 20250613_194943.mp4Don't know how to add a video...??

-

w3wilkes started following 1973 240z Custom Wiring From Scratch

-

1973 240z Custom Wiring From Scratch

I'm all LED except for the dash. I used a couple of these from Amazon for blinkers and emergency flashers and they've worked just fine since I installed them back in 2017. Amazon.com: VOFONO 2-Pin Electric Flasher Relay, 12V Heavy Duty 2 Pin Compatible Automobile Motorcycle Bike Scooter Fix Turn Signal Bulbs Fast Hyper Flash,Two Prong Round : Automotive

-

Loss of acceleration when hitting gas hard

Haven’t solved it yet. Having work done on the house and can’t get my car out of the garage. Hoping in a few weeks I can look at it again

-

Do you like the hybrid view or the traditional forum view?

YES!! Glad to have you back :)

-

-

Took some pics of my 240z side-by-side with my 2025 400z

Wow! 😝

-

Loss of acceleration when hitting gas hard

I’m not sure, maybe you’ve worked this out while I’ve been in exile. I have to assume stock L-Jetronic EFI? If so, open the air flow meter and tighten the spring a bit.

-

Do you like the hybrid view or the traditional forum view?

Miss me Steve?

- Series I is more hesitant to Start

- Series I is more hesitant to Start

- Last week

- Z Parts For Sale.

-

Z Parts For Sale.

- Z Parts For Sale.

brenan318 joined the communityTerrapin Z started following Z Parts For Sale.- Z Parts For Sale.

- Black panel on floor?

Got it, I'll give it a look. Thanks!- Black panel on floor?

I mean both, but better to remove wipers and pull cover. I had this exactly problem. We welded a patch in the floorboard at that spot to repair it. Also repaired the holes in the cowl around the air intake. So the water was leaking down the inside under the carpet so you couldn't really see it.

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.