-

280z Inner Door Latch Rod Coupling -- Rubber

Might be easier to just use a neoprene washer then. Similar to this: https://www.homedepot.com/p/3-16-in-x-1-2-in-Black-Neoprene-Washer-4-Piece-815728/204276433?MERCH=REC-_-pipsem-_-204276387-_-204276433-_-N

-

Zup started following 280z "Rally Sport Mirror" Glass , 280z Inner Door Latch Rod Coupling -- Rubber , [2022] What Did You Do To/with Your Z Today? and 1 other

-

280z Inner Door Latch Rod Coupling -- Rubber

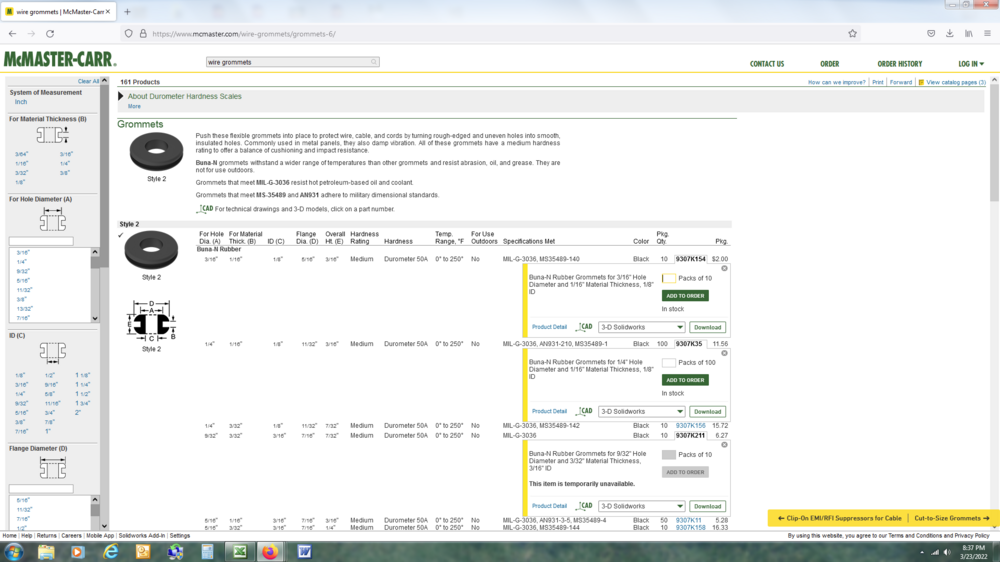

Generic rubber grommet of the proper size should do. You'll need to determine the size of the hole in the latch housing the latch rod runs through and the size of the latch rod itself and choose a size that is close to the same. The flanges of the grommet will sound deaden the metal to metal contact of the latch rod ring end and the metal washer on the spring side. I think that was the intended reason for the rubber cushion. You will probably have to razorblade split the grommet to install it-- using superglue to join the split after it is in place. The grommet may be elastic enough to slip over the ring end of the rod linkage----I don't know---worth a try. Scroll down to Style 2 in this page link: https://www.mcmaster.com/wire-grommets/grommets-6/

-

Putting in a replacement L-28

Totally agree with that John! Glad your issue came to a successful resolution. Your research into a source for reconditioning the heater valve for the 280's is a huge help to anyone faced with the problem. Very significant!!

-

[2022] What Did You Do To/with Your Z Today?

Love the iron cross rims on your Z!

-

Putting in a replacement L-28

What is the overall curved length from the end of the valve to the core tubing and what does the ID of the hose need to be? I've got an impressive bunch of original braided rubber hoses here at home with all sorts of molded curved sections to them. Might be we can match up a length and ID from a section of one of them.

-

Alternate OEM door mirrors?

There IS a RH factory replica available. https://www.ebay.com/itm/154785975290?hash=item2409f68bfa:g:rPYAAOSweEFbCevK

-

280z "Rally Sport Mirror" Glass

Alternatively---if the outside glass surface is in good condition (no scratches) the original glass can be re-silvered on the backside and will be good as new. I've done this several times on interior rear view mirrors. contact: http://mirrorresilvering.ca/?page_id=113

-

Zup started following Brake Booster 6” kit , Alternate OEM door mirrors? , Windshield Wiper Assembly and 2 others

-

1971 HLS30-14938 "Lily" build

So sorry for the issues and frustrations you are going through Charles! I know you were making every effort to get Lily finished in time for Birmingham. It may still happen! My Christmas wish for you is that everything goes smoothly from here onward. You've paid enough "dues" to the Z gods for the things that went south. It will take a while for the sting of this to diminish, but you know Lily WILL BE beautifully finished. You won't accept anything less.

-

Alternate OEM door mirrors?

Just realized you have a 77 Z. Did you use the OEM 77 mirror or one for a 240Z?? Don't know if you have seen these Jeff: Here's a link: https://www.ebay.com/itm/154739819489?hash=item24073643e1:g:rPYAAOSweEFbCevK Funny that the price of a reverse engineered passenger side copy of the 240Z OEM mirror is about half the cost of a new Nissan driver's side one!

-

Windshield Wiper Assembly

I've used Super Start Battery Terminal Protectors from O'Reilly's Auto Parts. Part #:01396 They come in a package of 2 that have a couple of different size felt washers pre-cut in each. Just separate them to find the right size for your linkage posts. Grease them with some white lithium grease. Or--this from Walmart:

-

Z Proto: The next z reveal

@reefedjib Read through your posts with interest regarding the calculations for your "future build". You got @Captain Obvious attention. Nice work. You mention Dave Rebello and calcs that feature a 3.2 liter with triples several times. As a possible alternative, I would suggest you contact the Honorable Eiji Hosami at Datsun Spirit in Manassas, Virginia and discuss your plans. With you being in N. C. he would be a much closer build partner. If anyone can achieve the results expected from these figures, he would be it. Here's a teaser : http://datsunspirit.net/spl-series/ Peruse his website-----you'll like it!

- SU fasteners suppliers/throttle shaft?

-

The Pinnacle of Ignition Technology!

Assembled several Heathkit and Dynaco amps, preamps and tuners for myself and friends as a teen. I still have some of the Dynaco stuff. Did not know Heathkit was into automotive ignition though!

-

Brake Booster 6” kit

I agree with Charles.

-

Parts Wanted: 280z stock right front lower valance

Looks like the passenger side to me. He has several photos. Seems like I saw the driver's side in another one of his listings. Whatever---the short scalloped edge profile matches what John posted he was looking for originally. Ask him thru e-bay.