Everything posted by ETI4K

-

Paint Day!

They look great. Tell us about the paint (1K, 2K, cans, clear, satin, gloss).

-

Rust Advice 78 280z

It's also interesting that there's so much smoke. Is it coming from an active oil leak or is it part of the exhaust gases leaking out? If it's leaking from the exhaust system, you've a lot of blow-by. Sorry, I don't recall if you did a compression check. It's just all the sounds coming from your engine suggest a problem beyond valve lash, which is usually a "lighter" sound, like a tick (which it sounds like you've reduced). Your othrr engine sounds suggest larger masses with excessive clearnces as @Zed Head has mentioned. No one wants to pull a motor unnecessarily just to check bearing clearances, etc. but after listening to your vid, I for one would not be letting that car out of the garage just yet.

-

Rust Advice 78 280z

Sounds to me to still have some excessive valve lash, and maybe some others. Getting the valve lash right will quiet it down somewhat so the rest can be sorted. Adjusting them is difficult because once you have it perfect, you have to tighten down everything and the clearances change. Once you think you have it set, you need to rotate the crank and check them again. Also, the firmness of the slip of the feeler gauge is pretty important. How do you describe tight or loose or just right? When you get it just right, you'll know bc your motor will purr.

-

Rescuing the Ignition Relay

If you ever try it again, wire wheel/brush the steel until brilliantly clean, then use either solid solder with acid flux or acid core solder. The absolute key is to be clean.

-

Rescuing the Ignition Relay

What methods/materials did you use in your attempts to resolder the connection? I'm assuming the strap is copper and the steel cover had been tinned?

-

Rust Advice 78 280z

As best I can tell using a phone screen, everything looks wet. Always an encouraging sign.

-

Rust Advice 78 280z

Sounds absolutely mechanical, not exhaust. I'd check oil pressure first. Don't rely on the gauge. Either plumb in a mechanical gauge or pull the valve cover and be sure there's plenty of oil being delivered topside. Then, do a valve adjustment. If everything's okay thus far and you still have that knocking, I'd start thing rod bearings.

-

battery chargers

I got one last year - DSR. Best thing I ever did. Never had any love for Schumacher's cheap line products. I've been inside them several times. A friend did a LOT of research and bought the very best wheel-around battery charger he could find. It wasn't Schumacher. It cost him several hundred dollars. It immediately presented with a problem, so inside we go. What an absolute pizza chip. Seriously. Reminded me of some common and familiar low end chargers. Back it went. I know a jump box isn't a charger, but I have to say it's much better for getting a machine going. I think I have 9-10 battery-started machines. Between flat tires and dead batteries, it's hard to keep 'em ready to go.

-

Finally Got My Garage Mahal!!!

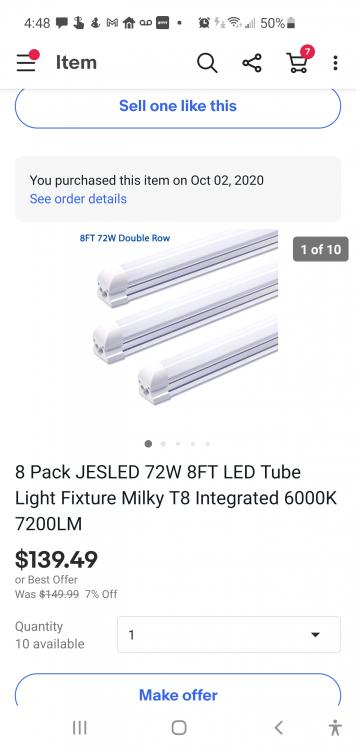

I used the pack of 8 led fixtures from EBay (and others). They are very lightweight, very easy to install, and very bright. My space is about 24 x 26. I need at least 4 more to lighten up two sides. Easily worth the money IMO. I've had so many different workspaces and none ever had light, so I've done this many times. My only recommendation is to buy their pigtails to get the spacing you need.

-

Another Z to see the roads again...

Forgot to add this...Frame Support Concept.pdf Frame Support Concept.pdf

-

Another Z to see the roads again...

It's amazing how long it takes to get something done. I've essentially finished the floor pans and the fit up of the floor supports. I still have a lot of weld blending before I can say they're finished-finished-done. Before I burn the support rails into place, I have to rebuild the frame connectors and then tie it all together. I keep trying to give myself a path backwards in case I find a major, uh-oh! so my weld progress is somewhat strategic. I cut out a bit of solid metal that was part of previous repairs just to reduce the number of joints needing welding, and grinding, and flattening, and blending, and... So now, I have some funky looking patches that had to be made, but will disappear eventually. Yesterday, I cleaned the inside surfaces of the floor supports with muriatic acid. Wow, that stuff is fast and thorough. Removed oil, dirt, and all the weld oxidation/burn that would be impossible to get to with a wire wheel or even media blasting (no pics). Then I coated the interior surfaces with ZRC. At some point down the road I will access every hidden cavity I can and shoot ZRC everywhere, then cavity wax. What I am trying to do now is reinforce the interior space of the frame connector and floor support area. I always try to work with material I have on hand first - and that happens to be 1/4 plate. The idea behind it is the flat bottom will take any direct hit to the frame rail (and be adequate to prevent denting of the bottom surface of the frame rail). The load from the hit will pass through the vertical sides upwards to the flat top portion which will spread out the load reducing the stress on the floor sheet metal and avoiding and deformation. Up. To. A. Limit. When I install the internal supports I will not weld them as I don't want a large surface area that can't be coated to prevent rusting, so I will probably set them with epoxy. The epoxy will provide 100% contact between the support and the sheet metal below. This should make it very difficult to deform the floor support/connectors. It's a plan anyway.

-

Finally Got My Garage Mahal!!!

Long ago, a friend was using an HP calculator. I picked it up and started playing with it. He said, "Careful, if keep that up, you'll never go back to algebraic." He was right. After 15 minutes I went back to my TI and could not operate it! Seriously. Everything was suddenly foreign, like having to push " = ". Still using a 48SX bought in the 90's

-

In-cabin fuel smell

Carbs or EFI? If carbs, it could one or more is venting an overflow of fuel in the carb bowl. Debris can hold the needle valve open, or may have lost a float to old age. If EFI, it'd be obvious if a fuel hose was leaking since it's at the same relatively high pressure all the time. If a hard line is cracked, perhaps it only weeps when the motor moves on accel/decel.

-

Rare and super rare Z - parts pricing! JUST ASK your question here!

That looks to be very useful indeed!

-

TechnoVersions Differential Mount

Not sure how yours is configured. I get you are using the stock mount below, but are you using the same PU part as @wheee! at the top - so the diff is constrained from moving up or down, or is there an air gap above the diff and a different snubber? I know using the same part as Mark would be redundant, but as I am planning to use the same hardware, I just want to be crystal clear.

-

Another Z to see the roads again...

I'm considering fabricating new seat supports. Mine are not damaged by rust, but between work done a long time ago (they were removed and welded back in), getting them out this time, and now having removed the driver side hump, getting them to look decent would be a bit tricky. What's nice about them is they are lightweight and strong. I can't form sheet metal to achieve that, so my design would have to be based on available shapes - tubes, angles, etc. The real loads to worry about would be shearing forces on the welds and bending moments on the pedestals during rapid acceleration events. I suppose during rapid deceleration the seat belts are doing the bulk of the work. Other than that, they just have to keep me off the floor. A rough idea of what I am thinking, attached. If anyone has designs or pics of something they've done, it'd be great to see them. Seat Mount Bracket.bmp

-

Another Z to see the roads again...

Don't forget, it's been off the road and bone dry for about 24 years. Can't even imagine if it had been a driver for all that time!

-

Another Z to see the roads again...

-

Another Z to see the roads again...

I also decided to pull the guards for the seat belt pockets. They weren't rusted, just beat up a bit.I haven't quite finished them yet. Still polishing off weld-fills for the drilled out spot welds. I will locate new holes for plug welding that are not at the edge of the parts as many of these spots were.

-

Another Z to see the roads again...

The motor is on hold for the time being until I get the rest of the parts from the machine shop. Decided to go with a replacement head since a good one became available. Thanks @madkaw Got some work done on the replacement floor pans. Decided to remove the driver's side hump in the tunnel. I still have to make and weld in new sections for the reinforced rear corners, but it's mostly down to blending the welds, a little flattening, and then get the floor supports in.

-

COVID-19

You may be overly optimistic. Either that, or the gene pool has some strong survival instincts.

-

[2021] What Did You Do To/with Your Z Today?

Yep. That makes some noise. I'm surprised I can actually hear the turbine over the exhaust. The exhaust drone will really tire you out. I remember the first time I took a trip of many hours in a car with air conditioning. It was quiet, smooth, and QUIET. Those hours seemed to have passed in minutes. That said, that exhaust does sound real)y nice.

-

The blue 510

Is that how the shop was when you shot it? That's really amazing given all the opportunities for hidden dirt, dust, and spiders to want to get into that paint. Gives me hope for when I do mine.

-

Another Z to see the roads again...

Is that your combustion chamber volume? If so, what do your compression numbers look like? I think the reason the head didn't explode when I drove it is because they also cut the new pistons to have .000 protrusion from the deck surface, that's about 25 mils, so it kept the same compression ratio (close anyway). This whole thing is beginning to look a lot like a CF.

-

The blue 510

That looks really, really nice. Great color and shine. Way to go.