Everything posted by grannyknot

-

Project Boondoggle (or, so I went and bought a Z!)

I don't think it looks bad at all, looks good, very unique. Is the flocking black felt? That's what it looks like, kind of like a speaker cabinet.

-

L24 Battles Six S20's. Guess who wins?

I have never said the 432 is sh*t and I never would, that is just you overstating things again. But the 432 is not special either, maybe a notch above average. I was convinced of that before I read the the first post of this thread and just as convinced of it now, although the knowledge of that win for the for the L24 is a tasty little cherry. I know you want believe the 432 was/is extraordinary and you desperately want everyone else to believe that too, but the fact that you seem to be so afraid of is out and all anyone has to do is READ THE NUMBERS. Those numbers tell the real story, just a notch above average. Blue, great detective work again, apologies for cluttering up your thread.

-

L24 Battles Six S20's. Guess who wins?

Value is meaningless, it is subjective. Ability is measurable which is why the numbers are so important, if a sports car can't stand up to scrutiny of its numbers then I guess you are being "delivered a message telling you what you should have already known" but will never admit to it. The 432R was a very good attempt but the engine was it's weak point, it was heavy, overly complicated and too small which is why they dumped it. A+ for effort, B- for execution. The 432R with a better engine would have been formidable and as we see here in this thread, it was. Your ability for for self delusion is remarkable Allan, you just don't seem to understand what racing is all about. The winner of the race should not be taken into account? Are you serious?! Give your head a shake man. You are looking through the wrong end of the telescope again, racing and racing history is about objectivity, that is why the numbers are recorded in the first place. Please, at least try to keep yourself out of the equation.

-

L24 Battles Six S20's. Guess who wins?

So much for diamond rings and oil paintings

-

Nissan Factory restoration cars

I'll bet there are hundreds guys here who would enjoy reading that, I know I would.

-

HELP PLEASE

Sounds like you stirred up all the crud at the bottom of the tank, time to drop the gas tank and have a look at what's in there.

-

240z dashboard vin tag

I have a couple of old dashes, I could send you a vin tag so at least you would know the size, thickness, typeset and such.

-

My new garage tool

Here's how, I already bugged him about it, Replied: yesterday at 11:07 AM · Report Here's a couple more pics of how I made my shop light. I used two of the GE "Light Stick" LED bulbs. I tried to stuff the 100W versions in, but just couldn't make it work. I settled for the 60W versions. Just in case you haven't seen them, the "Light Sticks" look like this: I pried off the threaded bases and marked the plastic globes with a marker to cut them off shorter (without hitting any of the LED emitters inside): Hacksaw (or lathe if you just happen to have one) the plastic globes shorter and put two of them nose to nose: A little clear plastic tape holding the two of them together in the middle. You can't see it, because it's clear. Soldered some pigtail wires to the original connections that live inside the threaded bases, and some electrical tape just to keep those connections covered. The wires from the end bulb run down along the outside to join in with the bottom bulb. Those wires live around the back of the shop light when the reflector is installed: Slip the bulbs into the original fluorescent lamp base and pull the wires through: Put the original cord, outlet, and switch back into place and make the electrical connections: Close up of the highly complicated electrical work. With the fluorescent ballast removed, there's plenty of room: Put on your welding goggles, and remember not to look at shop light with remaining good eye!! Let me know if you need more help. -Bruce Quote Reply to this conversation... Unread Content Mark site read Home Messages Theme Contact Us

-

HLS30-00006 at the Crusher?

Read the first line of thread, it's a joke.

-

1973 240Z on BaT

http://bringatrailer.com/listing/1973-datsun-240z-21/ It's all ready at $9000 and it just listed, doesn't look like it has been messed with much. Whoa! Make two Z`s on BaT, this one is not so nice, http://bringatrailer.com/listing/1971-datsun-240z-15/

-

1972 240Z Steering Rack Bump Stops

I know I didn't replace the bearing, can't remember about the seal. As long as the bearing was surrounded by grease it will probably be fine. If any water got in there it will be at the bottom of the bushing that the pinion sits in, my rack was an early one with about 130,000 miles on it and the only wear I found was a bit in the center of the rack where the pinion spends most of it's time while driving.

-

WTB 71 Center Console

That's what happens when someone installs a later 5spd transmission and doesn't cut out a small notch in the console or bend the shifter, you can put it into 1st or 3rd a couple times but eventually

-

1972 240Z Steering Rack Bump Stops

You have to get that pinion out in order for the rack to be able to slide out, you could try soaking the bearing/pinion in penetrant and heating the the casing. If you can find a way to hook it up a slide hammer to the pinion that would probably do the trick.

-

Chasis reinforcement

This is a link to some pics that gnosez posted about 4 yrs ago, I have been looking for these for weeks so I thought I would put them up. Lots of great visual information, thank you gnosez. http://s160.photobucket.com/user/psanders240/library/BSR-260Z-IMSA?sort=3&page=1

-

Greetings

I hope you did her appliance installation for free, that's a great price. Welcome.

-

sweatys rebuild

This sounds like job for the concourse squad

-

1973 Rebuild

Looks great, was the laser to make sure the car was level or were you using it to mark off the cut line?

-

Thinking about installing an BMW M6 engine in my Z

^ what that hell is that? Are those truck tires?

-

Thinking about installing an BMW M6 engine in my Z

Well there is not too much to it, you can do springs in between the bars if you like. The plastic wheels are off those clothesline thingys, I looked for the old kind with the aluminum wheels but my local hardware store didn't carry them. The welded piece on the bottom is some scrap that I put on so it could be held in a vice.

-

Thinking about installing an BMW M6 engine in my Z

I know I have been busy working away and the shop is a disaster but I don't seem to have many pics to show for it, here are a few. Built a M/C - firewall brace to hopefully stop some the firewall flex and give a firmer brake pedal, put together a fuel/brake line straightener for the up coming brake line job, The passenger side rear deck was rusted out so ordered a new one from Tabco, I was only going to use part of it then decided to pull the whole deck plate. This is the good side, looked perfect before I cut it out. This the fix that Careless suggested for the clutch line, works perfectly, thanks Raff and I started in on adapting the 350Z seats today, just got the D/S done. Still have about 3" between the top of my head and the roof, the flash is making them look grey but they are actually black.

- 1976 280Z Restoration Project

-

240Z Fuel reservoir / vapour tank

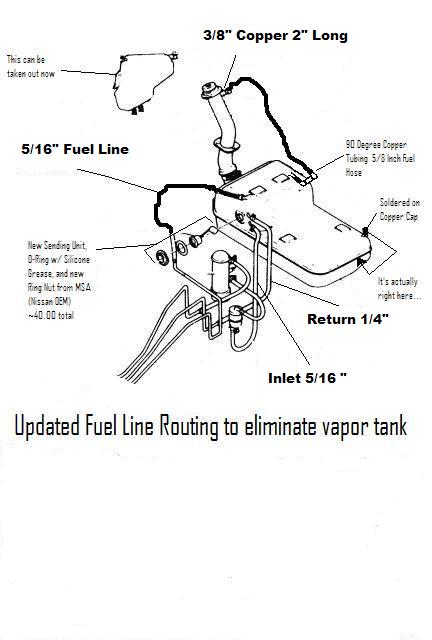

That is an electric fuel pump, the diagram is of a later car than yours. You'll notice the 5/16" fuel line at the top of the tank goes to a third fuel line that runs to the D/S of the engine bay, not sure if your /71 came with the vapour line set up, if it does then connect it up. If it doesn't then just seal up that line close to the top of the tank, your gas cap should be the vented version. If your cap isn't the vented version you can buy one from this young fella who lives just south of you,

-

240Z Fuel reservoir / vapour tank

The vapour recovery tank never actually holds liquid gasoline or at least no more then a few drops that condensate, all you really want to do is keep the smell of gas out of the cab. You could give the whole tank a sealing coat of fiber glass. I've never seen any reproduction plastic tanks and good original tanks go for silly money, the 73 metal tank can be made to fit but you'll need the plastic interior panel from a later year Z to fit over it. Many of those tanks have simply been deleted over the years, like this,

-

K & N AIR FILTER

Buy the cleaning kit

-

Paint cracking and stress fractures what should I do?

Brian, It's always a good practice to address rust asap but then a lot of us are dealing with rust that started 40 yrs ago. The hood you could wire brush the loose stuff off and spray it with some rust oil stuff until you can get to it, but those ridges above the quarter windows are something to be concerned about. That is where the roof was joined to the rest of the body, when I stripped the paint off my early 240Z I found a lead soldering in that seam, now if water has some how gotten under the lead then it is possible that it has oxidized and is bubbling up but it looks to me like there is some movement there, that the body and roof are flexing but not as one, that is not good. If there is movement in those seams then there will eventually be movement in other seams. If it is just the lead it is fairly easy to dig it out add some filler and repaint, if there is enough movement to break the paint then to properly fix it you have to go down to bare metal inside and out and re weld the seam. It's not like the car is going to fall apart or be unsafe but if it turns out that those seams are flexing too much then it's good to fix before other welds are stressed too.