Everything posted by Captain Obvious

-

Low voltage to speakers?

Yeah, I'm not yet convinced some light on the test light is a problem. As for what you're hunting..... Blown speakers? First question would be "What's your typical listening volume?"

-

Restoration of BringaTrailer 240z - HLS30-35883

Well it was a couple years ago when I was messing with those bushings, but I don't remember it being that hard of a fight for me. Are you maxxing out your 12T press? You can usually tell by feel of the jack handle when you hit the bypass limit. Are you hitting the limit? And that press you pictured is what I have. An old HF "A-Frame" 20T. I don't think they offer it anymore. Last I looked, they still offer an "H-Frame" in 20T and an "A-frame" in 6T, but for some reason it seems they dropped the 20T "A-Frame" a number of years ago. Probably unsafe or something.

-

Low voltage to speakers?

I'm thinking seeing a light up on the test light might not be a problem. Kinda depends on how the amplifier is designed and where you have the test light connected. And a test light is different than using a digital meter... The test light doesn't care about DC or AC. All it cares about is average power. So the test light might light up some even if you read zero on your meter on the DC scale. So how did you have the test light connected? One side clipped to body ground and the other side probing the speaker wires? And if yes, did you probe both speaker wires? What happened?

-

Low voltage to speakers?

Couple things... First, it's not DC, so if you're using a meter set on DC, you won't see anything. Then next, if it's music, it's a whole bunch of frequencies all mixed together up to about 20KHz. So even if you have a meter set on AC, it might not recognize frequencies that high. And finally, the voltage peaks will be proportional to how loud the music would be. So trying to make some sort of "portable scale" to measure things... If you've got a 20W system turned all the way up, it would/could/should? light a 20W bulb to a reasonable brightness. But if you've got the volume turned down to a reasonable listening level, the brightness will be way lower. Not sure I'm doing a good job of explaining this... Does any of that make sense?

-

Restoration of BringaTrailer 240z - HLS30-35883

Unless you are planning to go with poly, then burning them out won't do you any good. You'll still have to get the outer shell out before you press the new bushings in. You could burn the rubber out and then use a hacksaw to cut through the outer shell to relieve the retaining force. You don't have to cut 100% of the way through... It'll start to cave in before you get all the way through. Even with a couple thousandths remaining and it will be a lot easier to press out. I did mine (whole without burning) on a hydraulic press, and like most operations on a press, it all comes down to having properly sized drifts and anvils. A square (normal) force applied in the correct location with the proper sized backup anvil should do it. How many tons is your press? I've got a 20T and had no problems.

-

"Air Supplier Tube" Question

Couple ways... First (as foosman mentioned) as fuel is removed from the tank, the volume of that fuel must be replaced. Another way is if you park the car with a hot tank of fuel, that fuel will contract as it cools and could cause a vacuum. In any event, the solution to this is NOT the flow guide valve, but is in fact the gas cap. There is a one way check valve built into the gas cap that will allow air to pass through the cap into the tank to alleviate tank vacuum. The direction of air through the flow guide valve is uni-directional. They are check valves. No guarantees if they still seal after all this time and gunk, but they are supposed to be check valves.

-

"Air Supplier Tube" Question

The cleaner is not vacuum. The cleaner is atmospheric. OK... Physics dictates it must be a tiny, tiny bit of vacuum or the air wouldn't flow in that direction, but for the purpose of this discussion, the air cleaner interior can be assumed to be atmospheric, not a vacuum. The connection to the air cleaner box is simply a supply source of clean filtered air for the crankcase ventilation system. If the engine is not running, nothing flows in that tube. If the engine IS running, that tube supplies clean air to one side of the crankcase to replace the air that the PCV sucks out. The PCV side of the loop (connected to manifold vacuum at the balance tube) is at a much higher vacuum than the tiny tiny amount of vacuum inside the air cleaner box. And that's why for the sake of this argument the inside of the air cleaner box can be assumed to be atmospheric.

-

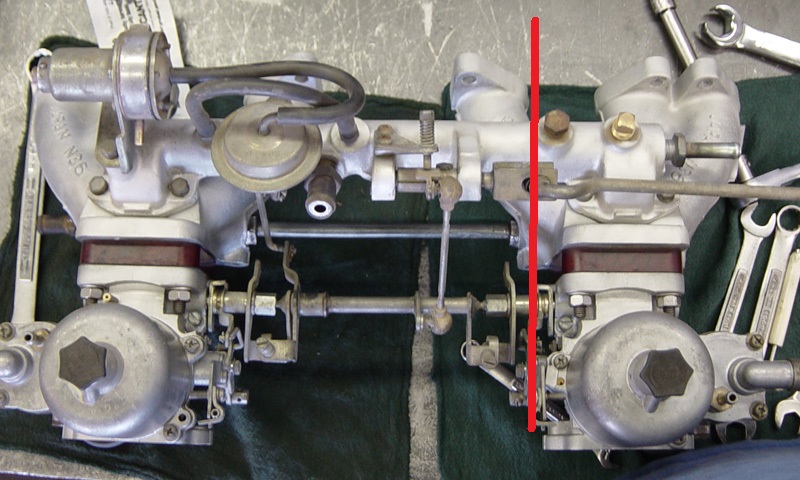

Carb Linkage arms. Are they Different?

You can get a rough idea of the difference between the two by looking at where on the intake manifolds the joint between the parts lands. Use the intake manifold and/or carb mounting bolts as reference markers. Using hoovered pics: Here's the flat tops. Note that the linkage joint is about the center of the rear carb: And here's the round tops. Note that the joint is further forward requiring the longer linkage piece:

-

280z Throttle Linkage

Looking at the video, it appears that the plastic ball socket up at your throttle body is cracked and a chunk is missing. That may account for some amount of play beyond what is considered "normal", but honestly I think it's just the nature of the beast. There are something like seven mechanical joints in the system and each one of them is a contributor to the total play. Add to that years of use and wear, and you have the pedal uncertainty principle. If you want to get rid of all of the play, the only real option is completely bailing on the original linkage and changing over to a custom cable system. That's what I did.

-

280z Throttle Linkage

I've seen much worse. Doesn't make your heel/toe learning any easier, but that looks pretty much normal.

-

Carb Linkage arms. Are they Different?

- 280z Throttle Linkage

There is a plastic bushing in the linkage piece mounted to the firewall that started sloppy from the factory and has only gotten worse over the years. It is not replacable as there is a metal joint swaged into place that prevents disassembly. Many moons ago, I rebuilt one, spending a completely unprofitable amount of time milling the swaged metal off so I could take it apart, making a new bushing, and threading the previously swaged joint for reassembly. Turned out great, but I would loathe doing it again. As for the spring and washer joint at the end of the hook... It looks stock to me. Maybe a missing washer between the spring and the linkage? But no... That system was not dreamed up by your PO. Nissan did that.- Carb Linkage arms. Are they Different?

The linkage piece that mounts in the balance tube is very different between the round tops and the flat tops including the location of the slot where the shepherds hook connects. The round tops require a longer shepherds hook. I'm not an expert at reading the parts fiche, but it seems to me they did use different parts. Goes like this: 12 ASSY-TORSION SHAFT A 18300-E4600 L241 18300-E4601 L24 7206 18300-N3300 L24 7207-7307 18300-N3600 L26 7308-7408 18300-N4310 L26 7409 I'm thinking you're looking for 18300-E4600 or E4601 which were used until 6/72. Your car came with 18300-N3300 which started in 7/72.- Float-Sync

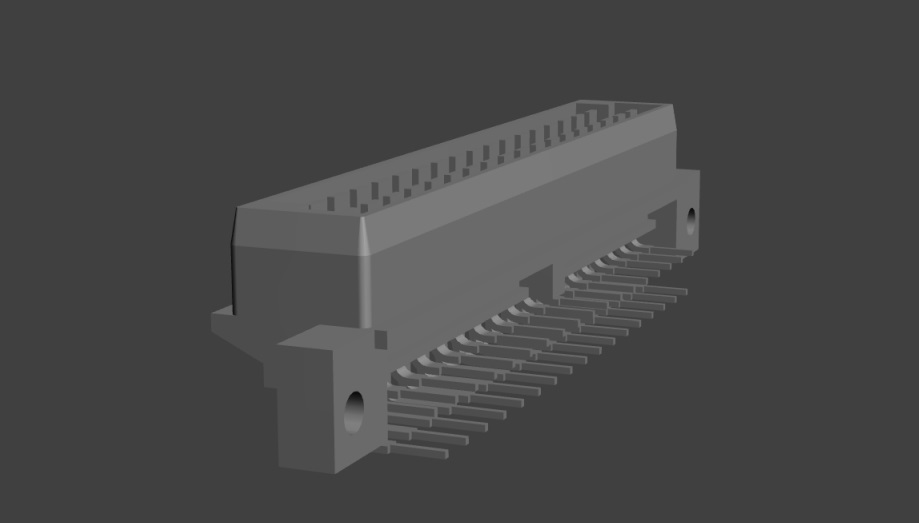

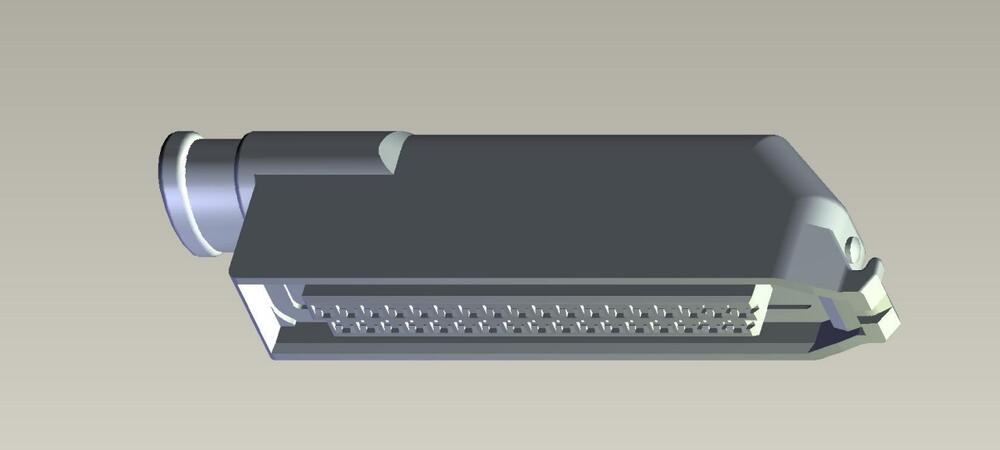

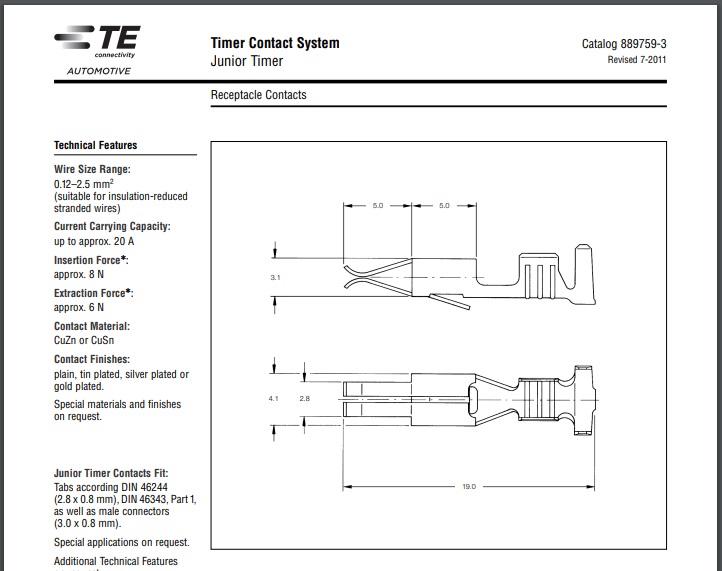

- 280Z ECU connector contacts

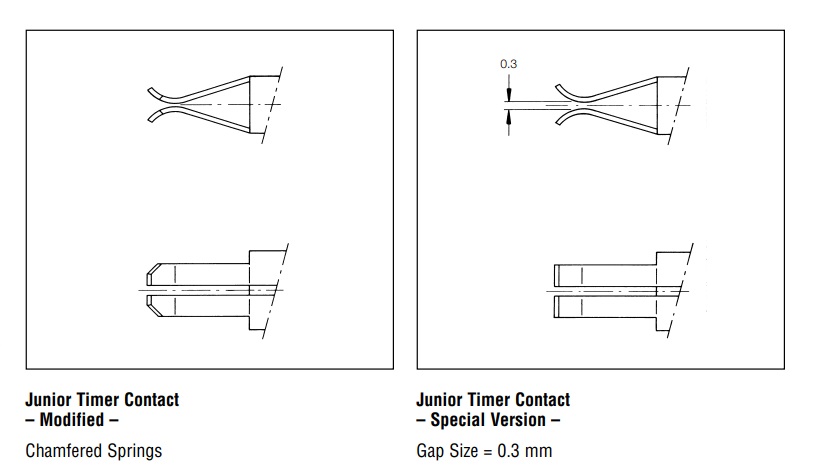

I took a quick look into this and I think the female contacts are Junior Timer (not JPT, just JT). Here's some pics and part numbers for you to dig around with. 825213-1 - This should be something close to the ECU mounted male tab connector: 827663-5 - This should be something close to the harness mounted female contact connector: And here's an example of the female junior timer contacts: I took a look at the harness I have here and it appears the contacts have a gap between the fingers, and this modification shows up in one of the catalogs as a "special version". Looks like this: If you need part numbers for junior timer contacts, let me know, but I suspect armed with the above, you should be able to easily turn up something that will work.- 280Z ECU connector contacts

I could easily attribute a 0.2mm difference to manufacturing tolerances or measurement variability. Maybe there's a burr kicked up on the piece you measured as a result of the shearing or forming operation?- 280Z ECU connector contacts

Hmmm... I thought they were junior power timer as well. I've got some connectors here. I'll take a closer look when I get the chance. I'm headed out of town today, so it won't be for a couple days, but when I get back, I'll look into it.- Chat GPT - AI Bot

Another fail: "Using a feeler gauge, measure the gap between the rocker arm and the valve stem." Not happening...- Z's on BAT and other places collection

He hates these cans!!!- Bypassing ballast resistor?

I started putting some of it here: https://www.classiczcars.com/forums/topic/67864-ignition-systems-analysls/ But it kinda fell by the wayside?- Bypassing ballast resistor?

Absolutely. Don't misinterpret my skepticism about location of the resistance (AKA "ballast"). The points you're bringing up are good stuff and completely valid: Yes, having the ballast resistance outside the coil will also keep the heat generated in that resistance outside the coil. And yes having an external ballast resistor allows for the ability to short across that resistance during engine cranking which could help providing a healthy spark even when the starter current is dragging the system voltage down due to it's large load. If the current limiting resistor is inside the coil, you lose that feature. I'm just thinking that if you've got a good enough ignition system such that you can still easily start the car even while the starter load is pulling the battery voltage down .and. you have dwell length in control in such a manner that you are dissipating a small amount of power in the coil, then it should not really matter where the resistance is. Either inside or outside the coil would be fine. But getting back to the OP's application, I guess the question is "Does the 75 ignition module meet those two above criteria?" I've never opened up a 75 ignition module. I've reverse engineered the 77 and 78 and done a bunch of poking around with the matchbox modules, but I've never opened up a 75. I would expect it to be similar to the 77, but I really don't know for sure. Maybe the 75 module design is weak enough that you DO need to defeat the ballast during starting, and maybe the dwell control is looser than the later versions of the module? Clearly by 78 they thought the module was good enough that they could use an internal resistance and eliminate the external ballast.- Bypassing ballast resistor?

I'm unconvinced. That article (which I must say was very poorly written*) talks about the concept of a "fixed ballast resistor" which is what the ignition system uses. They also referenced a simple LED circuit with a fixed resistor being used as a "ballast resistor" in the circuit. So it seems that a normal fixed resistor can be a "ballast". Same with the fan example. Granted, ballasts that are designed to purposefully change their resistance as the temperature goes up is a thing. And active ballasts like they use in fluorescent lights are clearly a thing too. But those are specifically designed to change their resistance as the current through them changes. I will dig around a little and see if I have a Z ballast laying loose around here. If I do, I will try to see if I can measure resistance changes with respect to temperature. I mean... Pretty much all things change resistance as their temperature changes, but I ought to be able to tell if the ignition ballast changes are "on purpose" or not. * that article seems to be a modified version of this page. Not sure which came first, but this one is (slightly) better written? https://www.electrical4u.com/ballast-resistor/- Bypassing ballast resistor?

I'm not sure which "he" you're talking about at this point... If you talking about your buddy with the 75 using a 1.6 Ohm coil with the stock 75 ignition module, then I think he is only 0.3 Ohms off from stock, not 0.8. The stock 75 coil was 0.5 Ohms paired with a 1.3 Ohm ballast. The result is 1.8 Ohms total. Is your buddy using a non-stock 1.5 Ohm coil instead of the stock 0.5 Ohm coil?- 74 260 Hesitates/runs poorly above 3500rpm in 1st and 2nd after car has heat soaked - runs great for first 30-40 minutes

So now that we've got all this distraction in this thread... I hope the OP has solved his issues!- Bypassing ballast resistor?

Didn't do what from the start? The current limiting? I'm thinking that as technology progressed and emissions and performance requirements got harder to achieve, they made the modules better. It takes a couple more components to do the current limit and those components cost a couple pennies. Looking at the insides of the modules, you can see the transition of the development technology from early seventies to late seventies. The early ones are metal can transistors on a PCB that was clearly laid out and taped by hand. And then by 77 they were using plastic case transistors on a CAD digitized board. The technology of both the parts used and the tools used to design that kind of stuff was moving VERY fast. Kind of a transition period in time. - 280z Throttle Linkage

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.