Everything posted by Zed Head

-

Rocker Geometry Woes

When you say "new rockers" what do you mean? Brand-wise. I think that might be part of the problem, The options are getting more limited. There seem to be cheap ITM brand or more expensive Paraut. http://www.stockwiseauto.com/product_info.php/cPath/1109_1277/products_id/1977610/Make/Nissan/Model/280Z http://www.ebay.com/itm/Rocker-Arm-NISSAN-280Z-280ZX-200SX-260Z-240Z-510-610-710-720-810-MAXIMA/310974615448?_trksid=p2047675.c100011.m1850&_trkparms=aid%3D222007%26algo%3DSIC.MBE%26ao%3D1%26asc%3D28808%26meid%3Dead19cd0317c4ffc8973541fc719bf9b%26pid%3D100011%26rk%3D1%26rkt%3D1%26sd%3D130906675945

-

Rocker Geometry Woes

Glad you're staying cool about the whole thing. Back to the big picture - I wonder if DPLLC isn't just buying rebuilt heads from the stores and reselling them. The two week lead time is really two weeks to get them from OReilly's. Might explain all of the packing material and surface rust on your last "freshly" rebuilt head. Let me know when you're sick of the whole thing and I'll stop. I can't resist exposing these kinds of people.

-

Rocker Geometry Woes

Yes, it seems like slightly worn Nissan parts might be better than new aftermarket parts. Probably the only thing better is brand new Nissan original parts. They also seem to be implying that the refinishing operation on the rocker arms can take off too much metal. Looks like still no guaranteed path to success on a cam swap.

-

Rocker Geometry Woes

Only adding this link to fill out the story. I feel like we should start a crowd-funding campaign to support rossiz's illumination of DPLLC's competency. Anyway, looks like there is another option for cylinder heads. Wonder where they come from. Actually a little cheaper then DP. http://www.oreillyauto.com/site/c/search/Cylinder+Head/02257/C0332.oap?make=Nissan&vi=1209237&model=280Z&year=1976 Who wants to be the lab rat? Post #163 of this thread from another forum is interesting also, re rocker arms and cams - http://forums.hybridz.org/topic/112117-new-cam-and-rockers-odd-looking-at-500-miles/page-9#entry1133995

-

240Z E31 Head Gasket Options

Seems like this would be the match.

-

240Z E31 Head Gasket Options

It could probably be drilled. Sandwich it between two blocks of wood. The early blocks and heads apparently had dead zones in the coolant passages that didn't flow much coolant. This lead to hot spots. The later design is probably just meant to keep cooling flowing at the rate that the pump could pump it and well-distributed. If your pump does 10 gallons per minute and you have passages for 50, you won't get good flow distribution. So, you could even consider improving the flow distribution in the head. But you'll have to make educated guesses. Too much knowledge to be comfortable now.

-

240Z E31 Head Gasket Options

-

240Z E31 Head Gasket Options

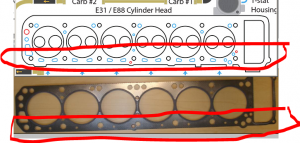

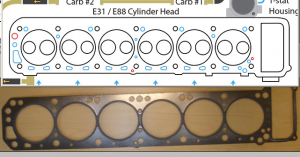

Comparing the Stone HG to the E31 diagram it looks like there are no issues. The gasket makers are just putting extra holes in everything. If there are two passages you get flow if not, you get a little round spot on the head. Edit - actually, what's interesting is that even the HG designed for the head has blocked passages in to the head. The bottom row has tiny holes in the gasket and some are blocked. The HG is the flow controller, not the passages. So you really need to compare an old E31 HG to a new HG to see what's what. I don't think the passages in to the head matter much.

-

240Z E31 Head Gasket Options

-

240Z E31 Head Gasket Options

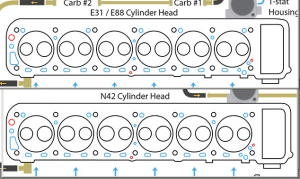

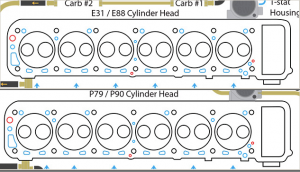

Here's a good thread from the past that I was able to refind. Were it mine I might just punch a new hole where the E31 needs it, if the gasket material in the area is sufficient. Looks like you'll just be missing two center holes. Size might be different though. Also made a composite picture so you can see the differences. I'm assuming that the guy who put the drawings together used the proper heads and knew what he was doing. http://forums.hybridz.org/topic/115160-l6-cooling-system-diagrams/

-

Sitting Uneven

Not really clear when the suspension was assembled. Maybe you didn't get the spring properly seated in it's perch. There's a spot for the ends of the spring coils to sit in.

-

240Z E31 Head Gasket Options

Any chance you could put the gasket on the head and see what holes match?

-

Superbowl 2015 Nissan Commercial

I remember laughing inside when a friend showed me his new Toyota T(u)RD truck. This new L(i)MP one is on the same level. Maybe it's a subliminal marketing gimmick, designed to catch the eye.

-

A Project Is Brewing...

You picked up a new L6 engine in Seattle?

-

Rocker Geometry Woes

Stepping back and looking at your whole saga, it seems apparent that the DPLLC guy doesn't know what he's doing. Or the mechanic he's using doesn't. Or both. Or he has a collection of heads in a warehouse somewhere and he just went and pulled another with the same problem as the first one. Maybe all rebuilt to the wrong specs. Regardless, it would probably help somebody out in the future to let DPLLC know that the second head's lash pads were off also. He either doesn't know or doesn't care. Maybe he's getting screwed by another guy who's rebuilding his heads. Still, he might be able to fix the problem for some future buyer.

-

240Z E31 Head Gasket Options

Here's an option not mentioned often. Oliver seems to know his stuff. The page might be dated though. 2012. http://www.datsunstore.com/advanced_search_result.php?keywords=head+gasket&x=0&y=0

-

Spark Plug Issue

How long/how many miles on the plugs? How red is red? I get a reddish tint on mine, I've read that various pump gas additives can leave a residue. (Just saw the MMT page. Same.) I've found that Permatex anti-seize, the stuff in the gray tube, gums up when used on the spark plugs. Mine were harder to get out than put in. I don't think it handles the heat well although Permatex says nothing about it on the label. I quit using it there and just use clean threads and a drop of oil now. I'll bet a clean plug run in and out of the hole will clear the threads, along with a little solvent. Gasoline is a good one.

-

240Z E31 Head Gasket Options

I've tried to logic out the issue of what the HG should fit and I came up with it should fit the head. Because the coolant flows from the block up in to the head, and the head cooling is more important than block cooling, I believe. Plus the fact that if there's no matching hole in the head, the hole in the HG doesn't matter anyway. The head gasket is actually designed to control coolant flow, that's why the holes are not as large as the holes they match in the block and head. As for bore size, you're really only looking at how deep the 1.25 mm gap will be at the head/block interface. It's essentially dead space that probably fills up with carbon pretty quickly and has little effect on the combustion process. Anyway, that's what my brain told me, based on information available.

-

Rocker Geometry Woes

Maybe Seahwaks offensive coordinator Darrell Bevell is advising DPLLC on how to choose lash pads.

- 1976 L28 Rebuild With P90 Solid Lifter Head

-

1976 L28 Rebuild With P90 Solid Lifter Head

Pretty clear that you've already decided... You haven't said if you've even driven the stock N42/N42 engine with dished pistons and 8.3 CR using the 1976 EFI system. So if it doesn't run right you won't know if the EFI system is out of whack or if it's the modifications you're making. You're going to end up with many unknowns on a primitive EFI system. Could be fun if you like solving problems, not so much if you like bolt on and go projects. I'd be interested in how the stock EFI system handles those changes but it will be hard to tell what's causing what. Good luck.

-

Rocker Geometry Woes

"green-eyed Lillith" brings up some interesting search results... So, it's looking like the loose pivot lock nut is the cause? Still curious. Not really clear how you received the head or what you did to it before driving. You have the most interesting thread going. My biggest problem right now is working up a way to modify my heater coolant control valve so I can fine tune the heat output (I have one of those Honda valves but small movement lets lots of coolant through), and waiting for a small oil leak to drop the oil level low enough so that I can add some seal conditioner (my leak-free engine started leaking). I might watch most of the game then leave for the last 5 minutes, like I did for the NFC Championship game, when they were sucking.

-

Rocker Geometry Woes

Bummer. Is that really a colonoscopy camera? I want one. Did you check any other cylinders? Still curious about cam timing and valve clearance. Although getting the rocker arm lodged on top of the retainer as it wiggled its way out seems reasonable also. There was probably a short period of time where the valve was still held up by the seal when piston damage could have been avoided. Sorry, I'm sure that doesn't make you feel better. Don't forget though - the Seahawks are playing in their second Super Bowl. A little bit of feel good. Unless you're from Wisconsin.

-

Wiring Upgrade Btw Alternator, Starter, And Battery

Since you're redesigning you might consider the battery as just another load and run a fused line directly to the maxi-fuse block. I think that connecting the alternator charge wire to the starter lug is just an inexpensive and convenient way to connect it to the electrical loads, for the automakers. That is actually two unnecessary junctions between the alternator and the loads. Each one drawing a few milliamps. I moved all of my connections to a central post, and run a separate 12 gauge wire to the battery for charging. The big cable is used to run the starter, and the wire from the alternator is connected to the central point. So after the engine starts and the alternator is charging, the current flows directly from the charge wire to the various loads, even the EFI harness power. My battery terminals have no extra wires attached, except for the ground wire on the negative terminal, and the starter only has the big positive cable. Just one way to do it. The connections all stay clean and uncorroded because they're not exposed to the acid fumes from the battery. Even the maintenance-free batteries vent a little bit.

-

1976 L28 Rebuild With P90 Solid Lifter Head

BRAAP's writeup says a lot more than just a statement about cylinder heads. That's a gross over-simplification. I think that where people tend to get misdirected on "performance" is in focusing on peak numbers. There are many ways to increase the maximum power that an engine will produce but, with the stock EFI system, it will probably run poorly everywhere else. Most of the tuning that is done with aftermarket EFI systems is "everywhere else", to make the car drivable. Lean spots at certain RPM will make the engine balky and weak at certain times, rich spots will make it stink and might foul plugs. I have an essentially stock setup, and I rarely get the engine above 5000 RPM, where max power would be. What makes mine a pleasure to drive, for me, is the way it pulls cleanly from idle at a stop light up to the next shift point, and the way it responds to throttle from cruising at 2,000 - 2,500 RPM. Or the way it cruises at 3,500 RPM if I want a little more jump when I hit the gas. Almost all of the performance stuff you read is race-focused,which is mostly wide open or closed throttle. Many people say that adding a tunable EFI system to the stock engine parts will add more "performance" than adding parts to the stock EFI system. Even higher peak numbers.