Everything posted by Zed Head

-

Brake fluid leak at master

Bright light and a magnifying glass will tell you a lot. Inside of the cone at the end of the metal line and outside of the cone down the hole. You might see a crack or deformation. You could even polish the surfaces if they look rough. Also polish the surface that the fitting rides on. It needs to be smooth so that the fitting can apply even pressure across the bell shape at the end of the metal tube. Focus on the surfaces that make contact. The threads are only there to apply the force.

-

saturday night music thread

From the 70's.

-

Z's on BAT and other places collection

The guys with the money, so funny. If they had their way people would have to pay to comment on the cars. The high end BaT car auctions are more like a big money poker game. Who's bluffing who. They don't want to know until the sale is over. https://bringatrailer.com/listing/1971-datsun-240z-345/

-

Z's on BAT and other places collection

Considering the cost of parts today ($20 half shaft bolts, see previous thread), this 2+2 might be worth collecting just for that purpose. It runs, but has a 4 speed. Looks like an R200 also. https://bringatrailer.com/listing/1978-datsun-280z-22-27/

-

What size bolts will fit?

Which hole? You could probably buy a small selection at your local hardware store for a few dollars. Try them out and you'll know.

-

Still struggling with car at idle after 8 years

- Z's on BAT and other places collection

- 1975 280z Build

It wasn't meant to be a link, just an abbreviation. Something in the browser or forum software does that automatically, I think. ithink.com link.com thislinkwontwork.com- 1975 280z Build

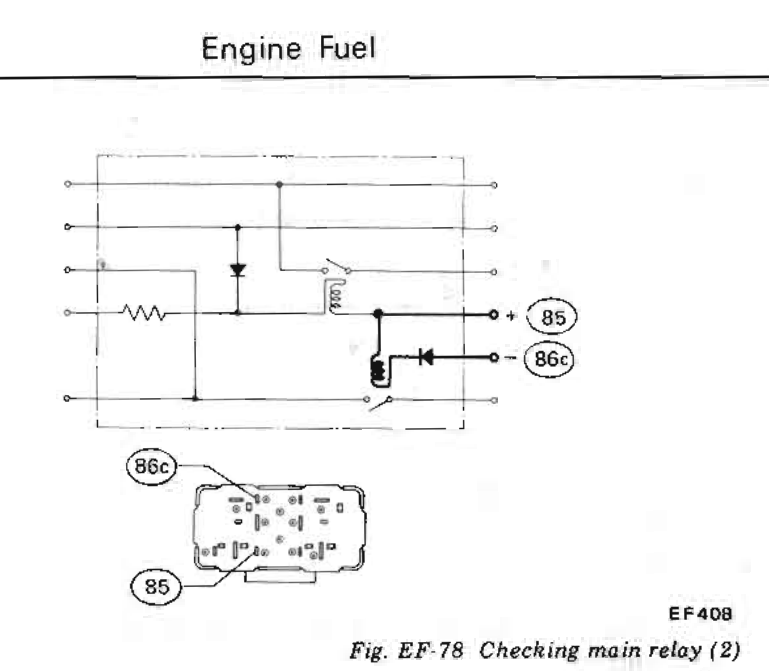

EFI/pump relay. Which one did you order? You didn't say. Don't overlook that the pump relay is controlled by the switch in the AFM. And that there is no "prime" like on today's vehicles. The pump relay is energized by the AFM switch or when the key is at Start.- Z's on BAT and other places collection

There's a driving video now. Speeding up and down an airstrip. Lots of woohoo comments. It's an interesting endeavor. Pretty dangerous for an unskilled driver. I wonder what the weight distribution is. Sitting at $30,000. https://bringatrailer.com/listing/1971-datsun-240z-345/#comments-anchor- Strange early z car electrical issue after being driven.........

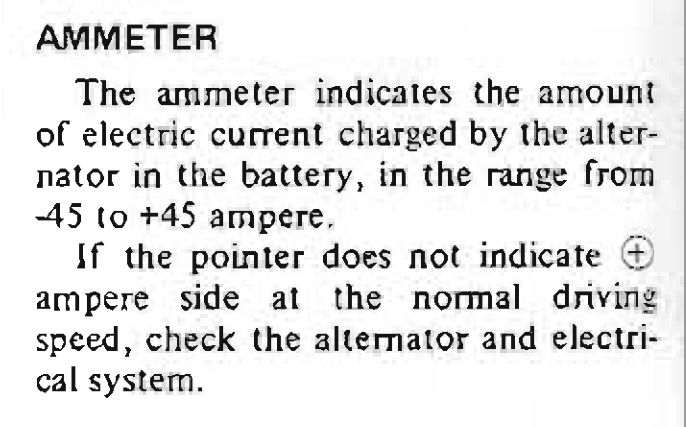

Not trying to be snarky, but isn't that what the ammeter is for? Seems like the cause of the problem was a bad connection that got fixed while disconnecting and reconnecting connections. I almost replaced a starter once because of that, and diagnosed a T connector problem at my alternator after I learned that lesson. Examination and adjustment with a pair of pliers (give the female side a squeeze if it's loose) is probably worthwhile on everybody's vehicle.- Strange early z car electrical issue after being driven.........

Maybe the spade connections at the adapter plug just lost contact. "New" connector in to old connector. Would have showed up with the T pin voltage check. Next time... Might explain the "meltiness" of the adapter also. Poor connections can produce heat.- Z's on BAT and other places collection

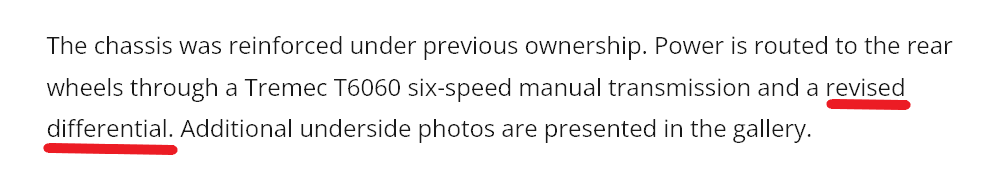

It got a nice price when it had the L6. $46,200. Not sure that 454 is going to add value. I'd guess most of the aftermarket parts went on after that sale. No driving video yet. 1971 Datsun 240Z VIN HLS3042112 | Hagerty Valuation ToolsHave you seen this 1971 Datsun 240Z VIN HLS3042112 auction result?- Need Help with Hooking Up a Speed Hut Tachometer

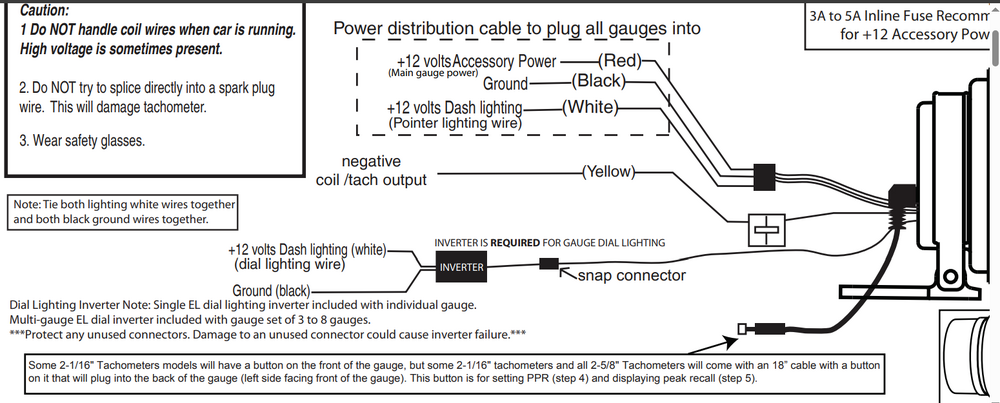

I was describing its function, not the actual material wire. The trigger wire for the new tach is its own independent circuit. I was also trying to tease out if you're replacing the stock tach or adding another tach. Are you sticking the new tach in the hole where the old one is? Your other basic question might be "how do I keep my ignition system functioning if I remove my factory tach?". Since they are tied together in the 240Z's. Just breaking the "how do I connect my new tach?" question in to its elements. Seems like you're on top of it. Good luck.- 1975 280z Build

Everything you need is here on CZCC.com The relay you show is not just the fuel pump relay it's a combined fuel pump and EFI relay. The relay that EuroDat showed is the proper replacement. It was used from 1975 through 1977. In 1978 Nissan separated the two relays. Nissan calls the EFI relay the main relay. They don't usually rust like yours because of their location. I'm still impressed by the challenge that you're taking on. Remember to check for shorts to ground before connecting the battery after you fix things. Those original pictures look like a wire fire waiting to happen.- Need Help with Hooking Up a Speed Hut Tachometer

It's a voltage triggered tachometer. Like those in the 280Z's. The yellow wire can, and should be, completely separate from any of your existing wiring. To run the Speedhut tach. Seems like your real question might be "what do I do with the wires from the old tachometer" to keep things working correctly. If you're replacing the stock tach. If you're keeping the stock tach, you could just leave it untouched, and wire in the new tach using the instructions. It won't affect the ignition system, since it just senses the voltage changes at the coil negative terminal. Just offering a reinterpretation of the original question. https://speedhut.com/content/instructions/2_and_2_58_tach.pdf- Z's on BAT and other places collection

Here's an interesting one. A Pierre’s Z Service Center creation, apparently. https://bringatrailer.com/listing/1971-datsun-240z-345/?- Strange early z car electrical issue after being driven.........

Without this the diode and alternator problems won't matter. No voltage, no charging. This can be checked with the alternator removed. Also, might as well check both pins. The top one should have battery voltage also.- saturday night music thread

A song with a woodworking reference. Just realized. And one about fruit with fungus in the name. What you eat you are...- Strange early z car electrical issue after being driven.........

Here's an old thread about a similar problem. (Edit - man, I wrote a lot of stuff back then.)- Strange early z car electrical issue after being driven.........

Good opportunity to learn how to use a multimeter. Check voltage at idle and while raising RPM. Some of the conversion plugs from MSA have been known to melt and fail. You can get a cheap meter for cheap at a place like Harbor Freight. https://www.harborfreight.com/7-Function-Digital-Multimeter-59434.html- Brake fluid leak at master

Sounds like you don't agree 100%. We're just offering possibilities. It's actually more interesting to some of us that the fitting was 3/4 turn loose and did not leak sooner. If it was mine I'd pull that line and make sure I didn't need more parts before starting the MC replacement. Might find out that you don't need a new MC, you actually need a new hard line.- Brake fluid leak at master

The rear reservoir would be for the front brakes. Unless you mean the reservoir for the rear brakes when you say rear reservoir. Neither reservoir should be pressurized. The pressure should only be created by the pistons in the MC bore. If you had moisture in the brake fluid it wouldn't be a surprise to have corrosion in the bore after 6 years. Then when you pushed the pedal to the floor you might have damaged the rubber seal inside. So, loose fitting allows reservoir ro leak dry, pedal goes to floor because of it, damaging MC seals, new MC leak looks like old fitting leak. Should have got that fitting tight the first time. Seems like it was very loose. Oh well.- Brake fluid leak at master

It's also possible that the metal to metal seal of the brake line was damaged when you changed the MC the first time. Pretty common for the tube to twist with the fitting when the fitting is loosened. The only way to be sure is to examine the parts. A magnifying glass and bright lights help. Take a close look and you'll see where the actual sealing surface is. A spec of foreign matter can screw things up. Something to be aware of if you do change the MC. The threads don't do the sealing, they just do the clamping. You can see the cone that fits inside the end of the tube in this image from Rockauto. That's the sealing surface.- Brake fluid leak at master

It's more likely that your MC seals have blown. - Z's on BAT and other places collection

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.