Everything posted by Zed Head

-

Recommendation for new radiator and elctrical fan for 280Z

Hey, are you sure that the AISIN has the cast impeller? I notice that they don't show it and their web catalog shows all stamped steel. http://aisinaftermarket.com/uploads/rh4yebzy_CoolingCatalog2013.pdf The catalog is interesting to read, regardless. I replaced my leaking radiator with a cheap Murray brand from OReilly Auto Parts. The mounting holes needed work but it does a great job cooling.

-

L26 blowing back through the carburator

Looks promising. If it was correct, cylinder #1 would have intake and exhaust lobes up, and the damper pulley timing mark (for setting ignition timing) would be on zero. Not sure what you mean with the 4 and 6 comment. You should really get a timing light and set timing. It's time. You can't force a valve open from inside the cylinder.

-

L26 blowing back through the carburator

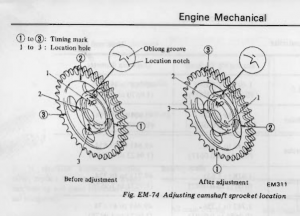

As madkaw said, forget about the bright links. If you can't see the corresponding link on the crankshaft gear, it's meaningless. If you turn the engine one revolution the link will be somewhere else. So you have a sprocket that was designed to be set up one time, with a new chain and never adjusted. Because there's no easy way to tell if chain/sprocket wear has occurred. I've also read on the old interweb that Cloyes started adding notches to the later sprockets, and only the old ones are notchless. Regardless, you have no way to confirm proper valve events unless you add a degree wheel to the damper and measure valve lift. Kind of a dilemma. Might be easiest to assume the PO knew what he was doing and work on everything else until cam timing is the last possibility. Or replace that sprocket with one that has the notch.

-

Restoring a 1977 280z! (My first z car)

The key turns in the button with no pressure on it, to get to the unlocked position. Then the button can be pushed down. In other words, if you're pushing on the key to try to push the button, that's not the way to do it. Just in case. Could also be the wrong key.

- wheeler dealers - 72 240z.

-

wheeler dealers - 72 240z.

Considering all of the problems people have stopping cam lobe/rocker arm destruction with new or reground cams, the "hard-welding" is surprising. The shop looks iike it's called R&R Cam, or H&R (it's on the side of the building). Probably never worked on a Datsun camshaft. I'll bet many of these car show cars self-destruct after the episode is done, Or the car sits in a storage area somewhere, where nobody can see what they really did to it. I'm a cynic, but they are just TV shows.

- wheeler dealers - 72 240z.

-

L26 blowing back through the carburator

Another thought on cam timing - since your sprocket has been replaced that means someone has been wrenching there. It's been known to happen that the cam shaft dowels have sheared, so even though in theory the worst the timing could be is at spec., or 8 degrees advanced, it's possible that things are totally screwed up. Still, simple stuff first, especially since it runs and the pressure numbers look good. Although, removing the sprocket nut is easy and will tell you if the sprocket is loose on the dowel, without actually having to remove it. You might do that first. No need to lock the chain, just make sure the sprocket doesn't fall off. Actually, lock the chain anyway, just for insurance. You really don't want to tear off the front cover if you don't have to, unless you're looking for a bigger project.

-

L26 blowing back through the carburator

Maybe that "8" is a "6". Sure looks like an 8. Here is the Cloyes Datsun part. Looks like yours. Pretty sure that I've read that the Cloyes sprockets don't have the notch.

-

L26 blowing back through the carburator

The numbers do look good. Check your sprocket to make sure it has the notch. It looks aftermarket, the factory sprockets have four holes, yours has three. Some of the aftermarket sprockets don't have the notch. If it doesn't have the notch, what will you use to reposition the sprocket? Oddly, S-482 comes up as a Toyota sprocket on the Google. And it's much easier to check ignition timing than to remove the cam sprocket. You might be getting ahead of yourself. Do the easy stuff first. Eventually, if you want to be sure on cam timing, just buy a new sprocket, with notch.

-

Totaled my 240z

If the doors still open and close correctly, and the gaps are even, it might be a fairly simple repair. The unibodies are pretty stiff.

-

L26 blowing back through the carburator

Here are some answers from his other thread on Hybridz. - "I'll definitely be adjusting the valves. The mechanical timing seems OK from what I can tell so far. I guess I need check the crank sprocket to be 100% sure since I have no idea whether the pulley is the original one or not. The ignition timing would be really hard to do given that the car won't idle. That's pretty much my goal at this point - to get the car to idle enough to check things out with a timing light. The distributor is from a 280ZX. I guess I forgot to mention that. I'm going to check the compression as soon as I get a chance. That should at least allow me to rule out a valve if the compression is OK. As for the lobes, I don't see anything that jumps out at me as far as wear goes, but I'm not ruling out anything at this point. "

-

Poor Gas Mileage - '77 280Z

I think that emissions control was a big part of fuel injection development. With an adjustable FPR and some tricks I can get low 20's mileage on my engine. But at the sacrifice of mid-range performance. Tunability is the major benefit of carbs, compared to old EFI systems. But the newer aftermarket tunable EFI will probably beat them both. I get about 21 mpg mixed highway and city in the summer, and 18 in the cold of winter. With things set for performance. There are several parts that could cause low mileage, like out-of-spec. injectors, a coolant temp. sensor on the high end of the resistance range spec., an ECU on the high end of the injector open time spec., an AFM on the high end, stuff like that. The easy way to increase mileage is to use an adjustable FPR. Then you can move the whole fuel enrichment curve down. The problem is finding an adjustable FPR that is as good as the stock ones. They all leak down and cause a new aggravation. I modified a $34 Bosch FPR but that takes some fabrication work. Some of the California cars have an altitude switch that cuts enrichment by about 7% (I think). If I had a CA car and it was rich, I'd short that switch and put the ECU in lean-mode. Just one possibility. Overall though, carb tuning is probably easier and quicker.

-

clutch 240z

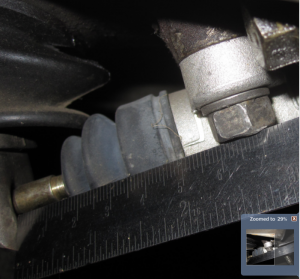

The transmissions from around 1971 up to 1983 are all the same, as far as the slave cylinder and clutch fork pivot relationship. That picture is from my 280Z, and it's an aftermarket slave cylinder so it looks different. But the distance from the mounting bolts to the end of the fork, at rest, should be the same for all of the Z car transmissions in that range of years, regardless of year or model.

-

Hard Shifting into Reverse

The one "trick" that always works but can be embarrassing if not done just right, is to put pressure on the lever while slowly letting the clutch pedal up, The gear will eventually move just enough to let the gears mesh. But, if the clutch grabs too quickly, you get a grind or a ka-chunk. It's odd that the problem came up with the oil change but maybe the Redline lets the non-synchro reverse gears gears snag each other, rather than sliding past to mesh. Maybe an unintended consequence of better synchro perfromance. Reverse is just jamming two gears together.

-

What To Do With 75 280Z

Another thought - daily driving an investment is scary. If it's worth a lot, it will probably sit in the garage. A Z that's not worth a bunch is more fun to drive, I think. And leave in a parking lot while you shop. Investments have to be managed to retain value. On the other hand, if you wait long enough, the 75 will probably increase in value. So time-frame has to be considered.

-

No Vacuum At Throttle Body Ports

On the throttle body. Check page EF-39. There's only two.

-

Removing Tail Light Housing - How?

The "rivets" on the top have a small plastic dowel in the center. That dowel has to be pushed through the rivet to allow the part on the other side to collapse and squeeze back through the hole. Usually, every part of that operation is difficult, the dowel will be stuck, the other side won't want to collapse, and it will be hard to get under the edge of the rivet to pry it up and out of the hole. Then, when they're finally out and the part is removed, you have to search all of the cracks and crevices for the little dowel. But that's how it's done. But, to get the tail lights out, you also have to remove the inner panel and remove a bunch of small nuts on long studs. Then carefully pry the light housing off of its old weatherstripping. In concept, it's quick, simple, and easy. In practice, things happen. THEN, to get the black part off of the lens and chrome so it can be painted, there are more tiny Phillips head screws. That will also be problematic.

-

clutch 240z

Here is a measurement from my car with the clutch pedal at rest. You can see that the boot on the slave cylinder is not stretched out like yours seems to be. You might have a short throwout bearing collar inside when you need a tall one. Take the same measurement that I show, with no pressure on the pedal, and see how it compares.

-

Triple Webers on 1977 280Z

Many carb people don't run vacuum advance. It goes away when you hit the throttle anyway. Even the early 280Z's (75-77, I think, definitely not 78) with EFI don't have vacuum advance until they're in top gear. There's a switch and solenoid that lock it out. Actually that might be the part you don't understand, you might have the top gear switch. Vacuum advance adds a little pep at part throttle, and some fuel efficiency but doesn't do much when the throttle is opened at low RPM. Have you measured initial timing? Confirmed that centrifugal advance works? Adjusted the valves? Every little bit helps, in addition to carb tuning.

-

What To Do With 75 280Z

Get it running. Sell it. Buy an early 240Z and make it your daily driver. The 240Z's are much better investments. 280Z's are great fun for a hobby and just driving. On getting it running - take the valve cover off and make sure the valves are closing. Squirt more oil in the cylinders, you might have surface rust jamming a ring or something. If you think the cylinder is messed up, it won't hurt much to run it on 5 cylinders.

-

Two steps forward,one step back. T/C rod length quandy

You could also cut the front bushing down and shim the back side out. Just a thought, same result. Here's an odd thought- the soft rubber bushings that Nissan used gave what is, effectively, an adjustable-in-use caster setting. Under braking, caster decreases, no braking, it goes back. Going to poly in front loses that. Probably depends on whether you're turning or going straight if it's a good thing or a bad thing.

-

12v. switched source

From what I've read, some of the electric fans pull a lot of amps. You'll probably need a dedicated wire and relay for it.

-

No Vacuum At Throttle Body Ports

The vacuum advance is controlled by "ported" vacuum. The port in the throttle body is closed when the throttle is closed. That might be why you didn't get any vacuum on that port. Most ports on the throttle body are "ported" or controlled by the throttle plate. Some may be direct though. But you can verify by cracking the throttle and feeling with your finger. If there's only vacuum when the throttle blade is open, that's one for the vacuum advance. Also, on the early 280Z's there is an electrcial solenoid that also stops vacuum unless you're in top gear. 1978 doesn't appear to have that though.

-

A better Auxilary Air Regulator

As described, it just lets air past the throttle blade. As long as it closes to the same spot consistently it doesn't matter much unless idle speed can't be controlled with the idle screw. Are you trying to solve a problem? Even in warm weather, the extra minute of high idle speed is convenient. The concept works, that's why it has stuck around so long and Chickenman has a modern part to do what the old parts did.