Zed Head

Free Member

-

Joined

-

Last visited

-

Currently

Viewing Topic: saturday night music thread

Everything posted by Zed Head

-

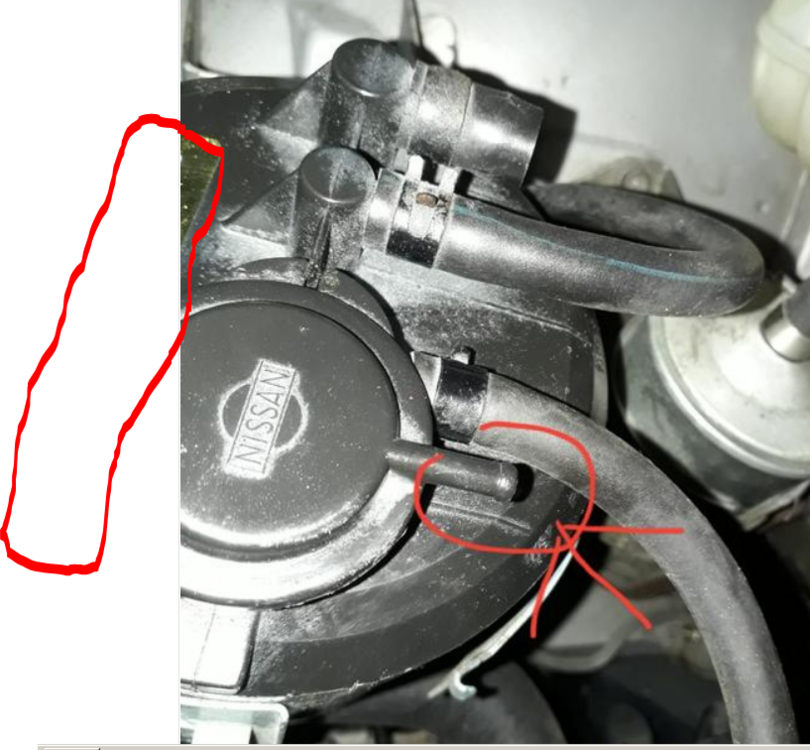

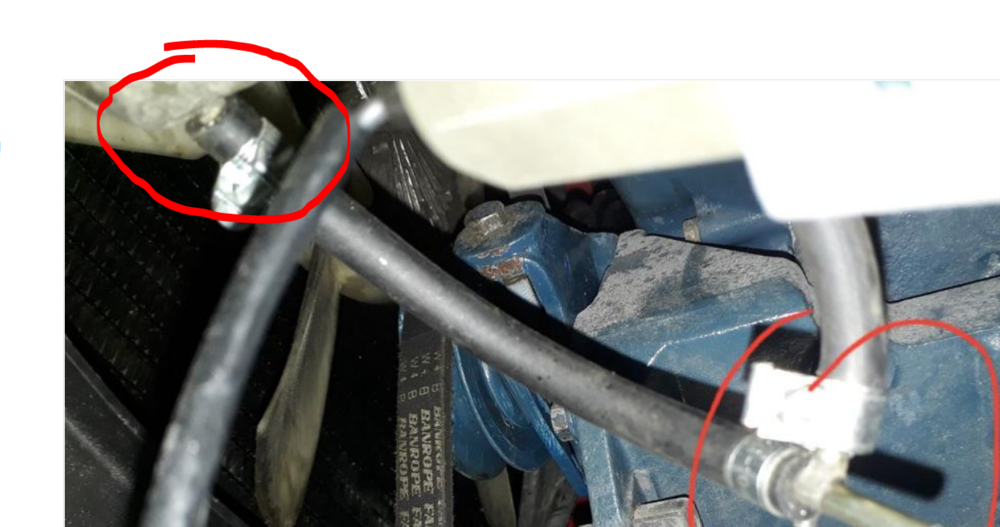

Mystery hardline

Actually, after I posted that I remembered where the hoses go. The small one with no hose is the control hose. It goes to ported vacuum on the bottom of the throttle body. The one next to it goes to a big port on the intake manifold. The far one goes back to the tank. You might be saying the same thing, I'm just confirming. The way it works is that when the throttle is opened the small hose opens the valve so that the big hose can suck air through the canister in to the intake manifold, clearing out the gas vapors that have come from the tank. It's a small amount of air but it's set up so that it's not a vacuum leak at idle. It's just a small vacuum leak when the throttle is open. I think that it's the only planned vacuum leak on the intake system. The only air that does not pass through the AFM.

-

5 speed swap

Did you break those 2x4's with your bare hands? And please tell us that thing is not what it looks like. Although, safety first...

-

Petronix Ignition Module

That is weird. The guys that understand how the "choke" works might know more. Can't see how a carb setting would affect electrical.

-

Mystery hardline

Firstly - tell your Dad to get that scratchy metal off of your paint. On the charcoal canister there is a label that tells where the hoses go. I copied and annotated a picture, below. And one of those picture looks like it is T-ed in to the PCV system. But the thing that it's connected to is a bigger clue. Added a picture of that also. Take a picture of that and we'll know more.

-

Petronix Ignition Module

What does it do? Or not do? One problem with the 240Z system is that all of the coil current runs through the tach. So, when you get more current flow it can cause problems. I've proposed this before, but I don't think that anyone has tried it. You could split the circuit through the tach by adding a bypass wire. This would cut current through the tach but let full current through the coil and module. That assumes that the problem is too much current. If it's too little current then you'd have to get a lower ohm coil. I'm not sure which is the cause, since the Pertronix instructions try to get you close to the current you had before. If your other coil was still good, you could put it and the ballast back on. If you don't have the Pertronix II, there is no coil "power" increase. It's just a points-elimination procedure.

-

How to remove '77 280z OEM door side mirror glass?

There was a discussion about this a year or two ago. Are you sure that you need to remove it? I had a similar problem with a Pathfinder and found that Nissan sold a stick-on replacement. It glued directly to the old glass. Allowed me to keep the heaters inside. In the thread somebody mentioned a place that would cut mirror glass to shape. Get some good contact cement and you'll be back in action with just a little extra thickness of the glass.

-

5 speed swap

Just remembered also that I placed something under the fork, inside the case, before hitting it with the drift. I think that was the hardest part, getting it supported.

-

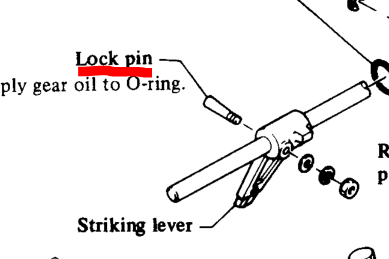

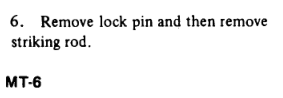

5 speed swap

I remember trying to figure out that puzzle when I took a 5 speed apart. I wasn't rebuilding, just tearing a broken one down. I think that I used a long drift through that opening in the case. There might have been some channel-locks involved also to squeeze the pin out. It's wedge-shaped on the end, like the lock bolt for the spindle pin. Apparently, it's supposed to be easy to get out.

-

Loses power under load

Yes, we can all see the posts. Hold your cursor over a member's name and the option to send a private message will appear. By the way, tapping a hot wire to an injector will not cause them to open. They are opened by grounding the power that is already there. So, if you take the plug off then you need to supply a hot and a ground. A 9 volt battery is commonly used, or you can ground them at the ECU connector, individually. Just sayin...

-

Need advice on brake rotors for '72 240Z

Motorsport's price isn't bad. Don't forget about shipping costs though. Rockauto has a selection. And, your local auto store can probably get them. The advantage there is that if they don't fit or are out of balance, you can return them. https://www.rockauto.com/en/catalog/nissan,1972,240z,2.4l+l6,1209169,brake+&+wheel+hub,rotor,1896 Or, you might think about having them turned. I had some truck rotors turned at the local NAPA shop and they did a great job. They can turn them while they're still on the hubs, so that you don't have to replace the bearings. Plus, they should keep their balance, and runout won't be affected. The grooves might look bad but you have to measure to know. Many options. Slotted rotors these days are mostly for looks. Because race car. New vehicles don't generally come with slots, or holes, in the rotors. Plus, they're prone to cracking.

-

Loses power under load

Jacob Silj just joined! Welcome JACOB! It looks LIKE you've worked on these cars BEFORE!

-

Engine Revs under Braking

Yes, that is the classic sign of a holed brake booster. When you press the brake pedal you open up a vacuum leak. People have been known to rebuild them. Disassembly is actually shown in the FSM. But most just replace them, with a reman. They're hard to find, and quality is generally poor. I don't think that you can get rebuild parts easily either. Edit - a simple test would be to disconnect and block the vacuum hose to the booster, then press the pedal and see if the problem is there. Whether RPM drop or rise depends on the size of the hole. 246, you're showing fixes for RPM hanging high while driving. Pretty sure the OP is just sitting still, pressing the brake pedal.

-

280 mile drive home in the rain....yes or no

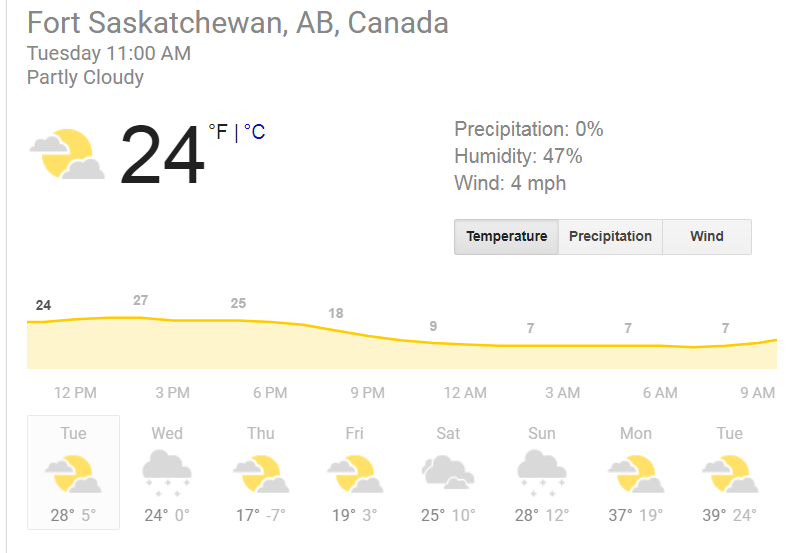

It's just water. Check out where ODOT used salt on the roads and avoid that route. Oregon doesn't generally use salt they only used it in a couple of experimental areas. Not sure what WADOT does. I think if you stay east of the mountains you'll be fine. The big storm isn't supposed to be here until Saturday. I've driven my 280 in heavy rain and it's no problem. It rained back in the 70's also, you know. Forgot to add a little map for those who want to see the PNW. I still remember trying to convince my friends in West Virginia that we had desert out here. Forget about the volcano.

-

Replacing a clutch

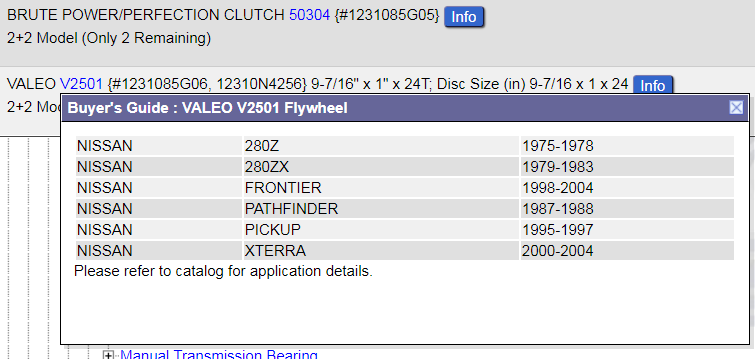

That seems to be the current scenario. There are few 225 mm flyhweels out there. People will have stories of the place they bought one at 3 or 4 years ago, but when you go back they're NLA. I think that the reason there are 240 mm flyhweels out there is because they were also used on various truck and SUVs. We'll all have to convert eventually.

-

Replacing a clutch

I assumed that you'd read the other clutch thread. It's just an option. Look at post #4 -

-

New from Vero Beach, Florida

Does ken know that he sounds like AI?

-

FOUND A LATE 71 240Z

Slovers was a well known shop for L engine head work, as I understand it. Sounds like a good find. Better make sure it's not high compression ratio, or at least know what the CR is. Might be a race engine, needing high octane fuel.

-

1980 280ZX flywheel and clutch kit advice

There are still automotive machine shops around that will resurface a flywheel, for about $50. You probably don't need a new one. You live in Ohio. There are probably five within driving distance of you.

-

What is this??

Probably easier, and less fuel to mess with. Plus you'll be under their anyway. Probably do it all in one shot. Don't forget to remove the gas cap so the vacuum relief valve isn't involved.

-

What is this??

https://www.klmperformance.com/inline-fuel-line-strainer-prefilter.html Dave, there's not really enough info to draw conclusions about that filter. They say "high flow" but don't give any numbers. So, nobody can say, with true authority, that it's right or wrong. Plenty of opinions out there though. The simple test would be to measure flow before and after installation. Looks like it has potential. The FASS fuel line filter/strainer element benefits: Are offered as a universal in-line fuel filter element. This high flow inline pre-filter element is an inline fuel strainer for pre-pump installation. Are available in either 3/8" or 1/2" I.D. sizes for in-line fuel line installation. Both of these in line pre-filters from Fleetguard have a 24-micron stainless mesh inner cage. Can hold a 13-gram capacity which prevents large particles from entering the fuel pump. The Fleetguard replacement inline fuel filters are designed for inlet side filtration only! Fleetguard In-line Fuel Strainers are a high flow element that will not restrict fuel supply to your fuel pump.

-

Replacing a clutch

Seems spendy. 240 mm flywheels are still available.

-

What is this??

Why not run something industrial? The farming industry dumps non-performing products pretty quickly. The aftermarket auto industry focuses on flash and buzz. Probably spend more on the fittings than the actual filter though. 1" NPT. http://www.circlecsupply.com/goldenrod-495-fuel-filter-with-1-npt-fitting.html

-

Replacing a clutch

Is it a lightened 225 mm flywheel, or 240? The 240 is the turbo flywheel, and the turbos were rated at 180 HP, I believe. You'll want the 240, with the right pressure plate and clutch disc. Not so sure that factory spec replacements are where you want to end up, with 250 HP, although starting there might be okay. Don't forget that it's torque and traction that overload clutches, and other drivetrain parts. And how you use it.

-

Need a rear bearing spacer!!!

No offense intended to you or your family members but I'd run that thing over to CO and let him have a look. Sounds like you have an odd mismatch of dimensions or something is bent. He did offer, and he does drive a train you know...

- 1976 280Z Restoration Project