Everything posted by Zed Head

-

remove door lock cylinder and handle-> remove window regulator?

I've done it on a 76 280Z. You just have to contort and have the right tools. I think that I used a small 12 point closed end wrench and turned a point at a time. Or something similar. The clip probably required needle nose pliers or similar. I remember the ordeal, but not the details. I seem to recall that disconnecting the actuating rod was hard also. Overall, a tedious pain.

-

78 280 Re-Assembly

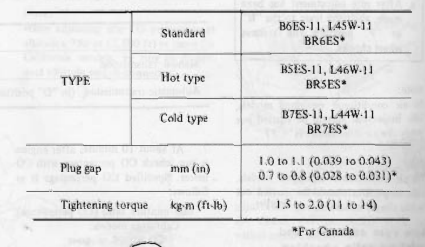

I had a 78 parts car and it did not have a ballast. I think that it was the first "high energy" ignition system used on the Z's. They even upped the spark plug gap. Except for Canada. Maybe Canada still had the old system.

-

1971 HLS30-14938 "Lily" build

Places that do a lot of bearing fitting often make test bearings by making the race dimensions smaller so that they drop in, instead of press in. Sanding or grinding the outer surface of your old bearing for example. If you have a belt sander you could probably do that to see if you have a dimension problem or a fitting problem.

-

Lowering Bottom Spring Perch

Never mind. Had a comment about preload but it was off. Should work fine. I've noticed that the travel of aftermarket shocks seems to vary. So you might find that certain shocks bottom out sooner than others. Seems like a good reason to go through all of the parts and see what's what.

-

72 240 slave cylinder bolt screw up, good day / bad day

Use Loctite and no washer.

-

Anybody else getting tired of this girl pointing her arse at you?

Maybe Mike's working on it or maybe this page made one of those Star Trek do-loops. This is what's down there now. I was talking to somebody about the ad topic the other day. If they would just be honest and call it tracking software people would probably be fine with it. Get rid of the ads and just track the web pages we visit. That's what "ad" software does. It's the tracking data that is generating revenue, not the ads that anybody actually clicks on.

-

Hello from across the pond! Searching for a 240z

Not a big deal but doesn't that shaft now have two "slip" points, one at the transmission and one in the middle? Probably fine, just interesting. Once you get the front case modified, boring the holes, and clearancing for first gear, to fit your S14, you can pretty easily swap gear boxes. So, even if you get a grindy transmission, it will be just a transmission drop and front case swap to get another in there. It's the machine work that takes the time, first pass around.

-

280ZX rear struts

Spring rate can also depend on the heat history and type of steel. There's a bunch out there about it but here's a couple of links. Plus the coil on the right looks like it's wound on a wider diameter so not the same manufacturer, probably. https://www.meadmetals.com/blog/types-of-metal-compared-infographic https://www.precisionsteel.com/spring-steel https://www.mw-ind.com/faq-items/what-is-the-difference-between-cold-winding-and-hot-winding-and-when-is-one-chosen-over-the-other/

-

Ignition issue and resolution story

Grounds, the oftenoverlooked part of the circuit... There's supposed to be a ground wire that runs from the distributor mounting bolt to the body. Yours must have got lost over time.

-

N42 Head rebuild

I'm going to guess that you'd need to have some made. The N42 has the biggest valves already, for that head design. The ZX heads have the same valve head sizes too.

-

N42 Head rebuild

1 mm oversize valves would not be a standard part. You'd need bigger valve seats also. Are you sure you can't just replace the valve seats and use standard size valves? Don't know what you're trying to do but your request is odd.

-

Anybody else getting tired of this girl pointing her arse at you?

Computer. Right now it's 3 ads and 5 CZCC images.

-

Engine Temperature Sensor Woes

Weird that our last two posts from yesterday have disappeared. About the condenser. I added a condenser to the negative circuit of the coil when my tach wouldn't function. It worked but I can't say exactly why. Many people have used the HEI module with no tach problems. This is essentially what I wrote yesterday. I saw it post. Good luck.

-

1971 HLS30-14938 "Lily" build

-

Gm HEI upgrade on a 78 280Z

I added another. But you want to make sure that the tach is actually connected first, of course. You didn't answer the other questions. The tach needle would probably do something if it is connected. Many people don't have any problems at all.

-

Gm HEI upgrade on a 78 280Z

Does the needle vibrate or twitch at all? Did you disconnect the original module by the fuse box? My tach wouldn't work right until I added a condenser on the negative side of the coil. It would just sit there and twitch and jump.

-

Follow-up on hatch won't open and a hatch lock tip

I would adjust it then so that it opens.

-

Anybody else getting tired of this girl pointing her arse at you?

I clicked on a few pictures, and recycled the page, and one or two changed pictures changed but then they came back with some nastier ones. Nasty and pervy.

-

1971 HLS30-14938 "Lily" build

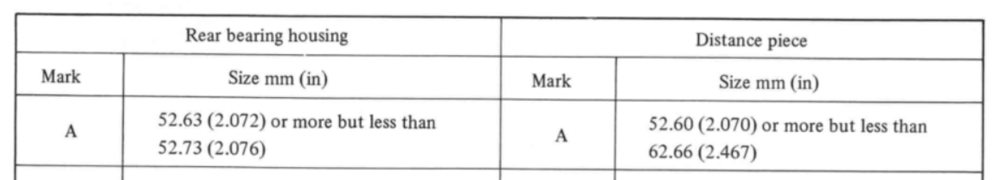

The hub casting itself should have a stamp on the outside. A, B, or C.

-

Anybody else getting tired of this girl pointing her arse at you?

It's been a while since I complained about this kind of thing, so what the heck...for old time's sake. I like to hit the "End" button to go to the bottom of the page. And I always end up seeing the same old end. This girl pointing her coochie at me, and showing some boob. Is there any way to get Google Adsense to switch things up a little? She must be getting tired anyway...

-

1971 HLS30-14938 "Lily" build

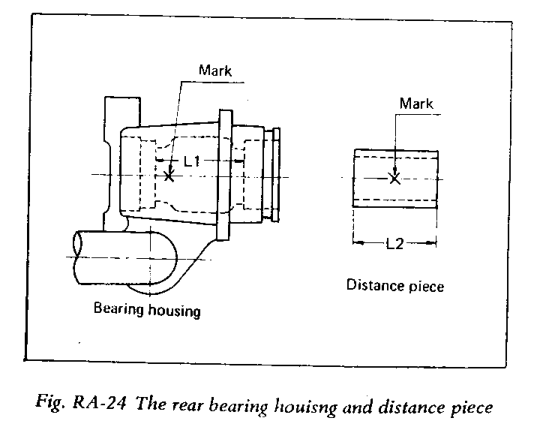

Looks like you need an "A" distance piece. Can't remember if you found a mark on the hub or not. .007" is much better than .020".

-

Follow-up on hatch won't open and a hatch lock tip

You should "follow up" in the original thread. It's not clear what the first problem was.

-

280ZX rear struts

If you didn't use the same springs then you can't really say it's the shocks. If you like the ride height of the car is it is now, with the old shocks, then the odds are in your favor if you take those same springs and put them on the KYB's. You might get an extra 1/4 to 1/2" inch. I'm sure that they're the same internal pressure as the KYB's we use on the 280Z's. We get a little pop from the gas struts too. Not 2" though.

-

280ZX rear struts

Why are the springs mounted? They should be on the old set of shocks that you reinstalled. It's looking like you just got some higher rate springs on your new KYB's. It's not the shocks it's the springs.

-

Engine Temperature Sensor Woes

It's pretty easy. You can do it temporarily in the engine bay as a test, before putting the time in to make it permanent. Or just get ahead of the eventual failure and make it permanent from the beginning. The performance is as good as the stock Nissan modules.