Everything posted by Zed Head

-

Vibration dampener thingy

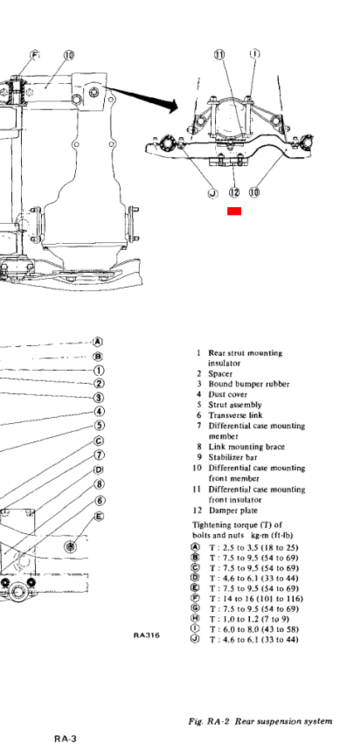

Just realized that yours has lost its bottom plate. The countersink is actually a bigger hole in the the bottom plate (missing in your picture). So it's broken and won't work anymore. Better get a new one. http://www.carpartsmanual.com/datsun/Z-1969-1978/axle/rear-suspension/83 https://www.courtesyparts.com/?p=catalog&mode=search&search_in=all&search_str=55418-N3701

-

Vibration dampener thingy

-

280Z for sale

Don't you have even one for this thread? p.s. I wouldn't put my email address in a post. That's just asking for spam. Use the message function.

-

Vibration dampener thingy

You have to read through that whole thread to realize that there was confusion about a retrofit, and a factory installed part. The factory part is just steel. Yes, they all look that bad. I've seen many in the wrecking yards, and I have three. Even Nissan tried to hide them, and only showed an edge.

- L28 Stroker Build - I need your advice :-)

-

We're bringin' back the Flat Tops!

It's fine as long as you don't crumble it up and create dust. Like the lead in paint.

-

Vibration dampener thingy

It probably had it at one time. What's surprising is that Nissan didn't at least polish them up after their introduction. 1978 is just as ugly as my 1976. They make a good portable shop anvil. Your link didn't come through. Here it is...

-

New 280z "Hawk" - wish me luck.

You might be able to flare the end with the proper flaring tool. I think it's called a bubble flare. If it's the return line it's under low pressure so not a big deal. Try to blow back through both. The return line won't have a restriction. That could also be the vent line, which has a check valve in it. The end of the vent line goes to the charcoal canister. You could also get a compression fitting, or put a 45 degree flare on that tube end and add the proper bubble flared stub piece of tube. Many ways to avoid a major replacement job and still be safe.

-

We're bringin' back the Flat Tops!

-

Just what the Doctor ordered. 1977 280z

Holy moly. Is this a resto or a resto-mod? It looked done to me when it was sitting on the trailer.

-

1979 280zx stalling under load. Changed fuel filter, had it liked at by auto shop. Appreciate your imput. Tks

Describe the stalling. That's the best clue.

-

1979 280zx stalling under load. Changed fuel filter, had it liked at by auto shop. Appreciate your imput. Tks

From one of the other threads - "Stalling under load. First thing we chsnged the fuel ilter. Put low octain gas in it. Had it checked out, fuel and air pressure ok. Has new plugs an wires. Any suggestions ? We thinking fuel injection sincere issues? Any imput or knowledge of same problem is greatly appreciated. Tks"

-

1979 280 zx

Stop starting new threads. Stick with the first one you started.

-

1979 280zx stalling under load. Changed fuel filter, had it liked at by auto shop. Appreciate your imput. Tks

Somebody on the forum probably has a solution but you'll need to provide better information. Does it die completely or just hesitate when it "stalls"? How much load? What did the shop say when they looked at it? Did they change the filter or did you? Did it run well before or is the car new to you? Not really enough to go on. Checking fuel pressure is always a good idea though.

-

Stalling issue(under throttle)

Here's another good SU link. http://sucarb.co.uk/technical-su-carburetters

-

1973 Rebuild

Pretty sure you'd have to have one custom-made. The nut is specially designed by Tokico to fit the top of the strut/shock and the top of the Datsun tube. Basically, three separate parts have to fit together.

-

Modded 71 Brings big bucks on BAT

Here's a more straightforward link. I couldn't click on that giant proofpoint link, too scary. Apparently the guy only had it for 9 months. Maybe a flip job. heramb dandekar. https://bringatrailer.com/listing/1971-datsun-240z-51/

-

Stalling issue(under throttle)

Read the chapter in the FSM about the carbs. Or just Google SU's. They're not "normal", they use intake vacuum to raise a piston which then allows air flow. What you see on the gauge is the vacuum on one side of the carb. A higher number actually means less flow. You might have a stuck piston. They also use oil to damp the movement of the piston. They're odd mechanisms!

-

Transverse link mounting bars

I think that he wants to make his own to save time. Probably fun to do also. He wants dimensions.

-

Pertronix/Tacho issue... Could it be?

Did you check the wires first or just roll the dice?

-

Pertronix/Tacho issue... Could it be?

The Pertronix ignition module acts, essentially, like a set of points. It makes and breaks the circuit. So you really shouldn't have to do anything special, wiring wise. If the tach is reading the current flow, there will still be current flow. If it's measuring voltage pulses there will still be voltage pulses. The problems seem to be either a matter of degree/quantity or of quality. The loop on the back of the tach is the common point for fixing the current measuring tachs. Are you just avoiding taking the tach out? Can't blame you. It's a pain. Ian at Pertronix has the answer. RCR's link in #3. I think that the voltage sensing tachs came out with electronic ignition in 1974.

-

Pertronix/Tacho issue... Could it be?

Does it do anything at all. The answer might be in the fine details. I would use a meter and check any mystery wires for power and ground before connecting them to anything. You should at least be able to tell that connecting them won't fry anything.

-

Another great source for lash pads.

But dealing with all of the weird numbers and formats and odd web addresses...I don't know.

-

New 280z "Hawk" - wish me luck.

Generally, the sealing process is meant for tanks with pin holes. Areas that leak. If there are no leaking areas and the metal is solid, then rust removal is probably good enough. That's the basics of it, I think. The sealing process has its own risks. One way to think about a decision.

-

280z heater valve

I've found that the various valve options all will flow way way more coolant than necessary to transfer heat. I even modified the attachment point on the lever so that it would only open about half way at full open on the panel control. It is still way more than needed. When you're building your system you might add some flexibility there. Otherwise you'll only be using about 1/2 inch of travel on the panel's heat control sweep. And make sure that you get a good firm closing of the valve using the heat lever. It's the only way to get cool fresh air. If the lever is partially open you'll get some heat transfer. The options that use the vacuum **** to close coolant flow are also limited so only the heat control **** works for that. For all of the work that they put in to it it's really limited in functionality.