Everything posted by Zed Head

-

77 280z timing problem ***NEED HELP***

It's very common for the distributor drive gear to be off one tooth. If he was able to get to the desired advance number on the damper pulley and timing tab then it doesn't really matter. That's why I asked what the number was. It's one of those things that won't hurt anything but isn't "right".

-

AFM/ Fuel Pump

Edit - actually that would be why it's bridged. Because the 77 plug is expecting the fuel pump contacts. The easiest way to short the wires is in the AFM itself. The ZX's used the oil pump switch and two relays to control the pump. They don't have the switch in the AFM. Are you sure it's a ZX AFM? Wouldn't be a surprise of the ZX AFM is a turbo AFM. Maybe it delivers more fuel for the stroker. You'll just have to cobble somehting together if you want the pump to run differently. You're well off of the stock system.

-

AFM/ Fuel Pump

No, somebody has been hopping up your engine. There might be other things besides the TB and AFM. The fuel pump contact might be bridged because they had low air flow at low RPM and the pump kept losing power. Might have a vacuum leak. Might have a big cam that flops the AFM vane around, causing the contact to open and close. I'd get all of the numbers that you can from the engine and try to figure out what you have. Get the head number, check the area below the casting to see if the head has been shaved. See if it's an N42 block or an F54. Might have flat tops or dished pistons. I just looked back at your first post and see "stroker". So, the PO has probably messed with a lot of things trying to get the stockish EFI to work. Might be quickest to just go to Megasquirt or Haltech or one of the other programmable EFI systems. Or carbs.

-

Gleason torsen identification

Should be 29 unless you want to have custom output axles made. https://forums.hybridz.org/topic/122244-r200-stubside-axle-spline-count-question/

-

GMB mechanical fuel pump failures

GMB should pay zKars a substantial sum. If they follow up on what he found he probably saved a large percentage of their business. The valving design is common to many many other brands. It's all right there in his thread. The work has been done.

-

AFM/ Fuel Pump

You should be able to. Study how the little arm causes the contact points to close when air pushes the vane open. Pretty easy to test, unbridge it, turn the key on, and move the vane. The pump should get power. Start power is through the relay, not the AFM. The AFM takes over when the key comes off of Start. Here are some good pictures. You might need to recalibrate the AFM if it's been messed with. http://www.atlanticz.ca/zclub/techtips/afm/index.html

-

280z Cold Starts, dies when warm.

Replacing the temp sensor would probably have little effect. The tweak is a cheap way to see if you are running lean, and to fix it. For whatever reason many of the old 280Z's run lean, maybe because the EFI system was tuned for 70's gasoline.

-

ZHome.com gone?

Isn't this Carl Beck's site? It's not working. @Carl Beck https://www.zhome.com/

-

280z Cold Starts, dies when warm.

The idle problem and the popping problem might be from different causes. But the fuel tweak might help the popping and stuttering. http://www.atlanticz.ca/zclub/techtips/tempsensorpot/index.html

-

77 280z timing problem ***NEED HELP***

What is the timing number with the distributor turned to the limit?

-

280z Cold Starts, dies when warm.

Engine running or not? Supposed to be 36.3, engine not running.

-

Differential fluid

I think that you can fill through an axle hole also. That square head is pretty easy to get the leverage on though. Not sure why you'd not remove it. No offense to those that didn't.

-

Differential fluid

p.s. I've found that a 12 point socket will often fit a four point plug like that one. The six points won't. But the grip is weak because the contact area is small.

-

Differential fluid

-

Differential fluid

A 1/2 inch socket drive fits. I've found that the wobble type get a better bite. The straight ones slip out easily. Run a torch flame around the plug to expand the hole. It's a taper fit, that's why it sticks out like that, and Nissan used a powerful sealant.

- Dieing issue

-

New Product Idea. Distributor Timing Plate Re-Design

These new products are hard to find. Maybe start another thread and link back to this one? Seems like the club would have a sub-forum for individuals who make cool stuff. Not just vendors. https://www.classiczcars.com/forums/forum/93-vendor-marketplace/

-

240z Timing Struggles

Set your distributor rotation adjustment to where you can get lots of advance if you need it. Put the screw in the slot so that you can turn the distributor clockwise with lots of space in front of the screw and just a small amount behind. Then set the slot in the shutter right about on the money. The leading edge is probably the trigger. Then you'll be right around zero when you start the engine and can turn the distributor to get the 8 - 15 degrees that you'll want.

-

240z Timing Struggles

While you're studying the problem, just remember that every time the shutter passes the sensor a spark is generated. So wherever the rotor is pointed will get that spark. The plug wire numbering is somewhat arbitrary. Some engines have number 1 at the back. V8's can have #1 on the left bank or the right bank. p A crank damper could have six marks on it, one for each cylinder. That would make life easier for everybody. The timing light would always have a reference mark.

-

240z Timing Struggles

My point was that #1 is wherever the rotor is pointing when the marks are lined up. The spark will jump to that electrode in the cap when the coil discharges. If you wanted to and didn't have the screw on the adjustment limiting you you could make any cylinder you want #1, as far as spark is concerned. The mark on the cap is for when everything like it's supposed to be. The engine will run fine even when things are off. Check that rotor position. It's the most important thing. Or, you could put your timing gun on other plug wires until you find the one that is right.

-

240z Timing Struggles

When you have the timing marks lined up on the damper at TDC compression stroke pull the distributor cap off and see where the rotor is pointing. That will be your "true" number 1 cylinder. Might be that your oil pump shaft is off and somebody moved your wires to compensate.

-

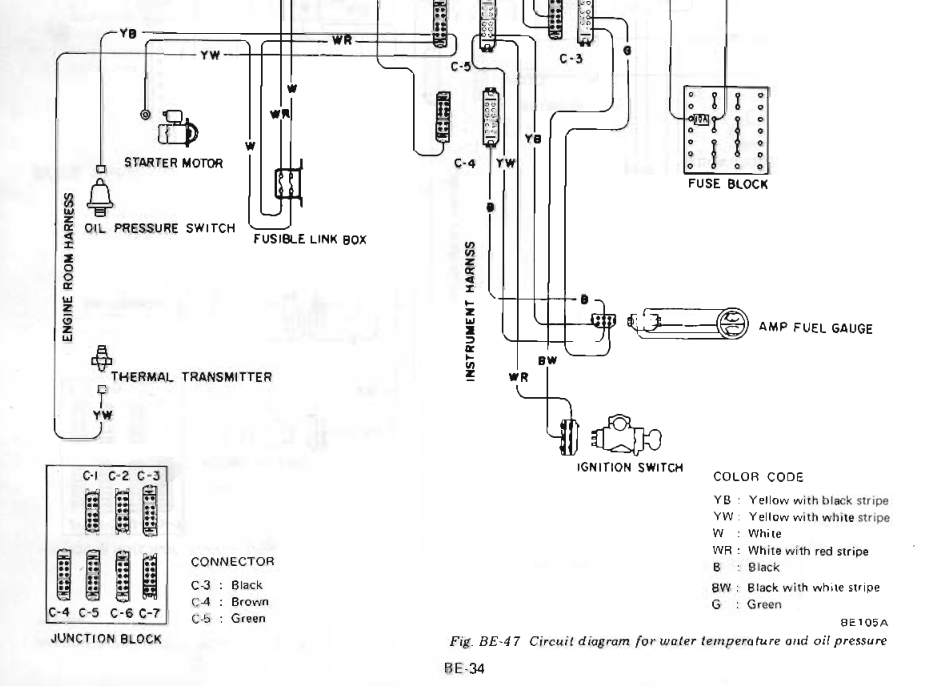

Gauges stop working then begin working again

There's a fuse. Could be losing contact. p.s. just realized that I found an error in the FSM, Check the bottom of the page and the label on the gauge in the diagram. The bottom of the page is correct.

-

Pro TunerZ vs Jenvey?

Here's a good thread about a new manifold design that was flow-tested at the end, and run, and dyno'ed. You can't just "eyeball" in a new design. Just doesn't work.. https://forums.hybridz.org/topic/51825-scratchbuilt-l6-efi-intake-manifold/#comments

-

Pro TunerZ vs Jenvey?

Don't forget balance. They all need to flow the same over the whole RPM range. 5 and 6 are pulling from the same pretty tight spot. 1 looks like it might get left behind. Hard to predict anything from just a picture. It will be a another fun story to follow though.

-

Weakness Revealed in the GMB and Spectra Mechanic Fuel pumps

Knowledge Base material...