Everything posted by Zed Head

-

Some 240Z's and a missed old car auction

A couple of local 240Z's, and an auction that just happened. Looks like they might have more. My ISP routes through Eastern Washington,apparently. Craigslist thinks I'm over there. https://spokane.craigslist.org/cto/d/1970-datsun-240zor-offer/6558803251.html https://spokane.craigslist.org/cto/d/1972-datsun-240z/6575931462.html https://spokane.craigslist.org/ctd/d/lotdatsun-280z-22-lucky/6584900181.html http://www.luckyoldcar.com/

-

L24 w/1mm bore. Will N42 head work?

1 mm over would be about .020" per side. The L26 bores are notched for their bigger valves from the factory, apparently. Seems like you'd need to do some clearancing. Here's a Hybridz thread on a similar issue to yours. @madkaw has done some notching. http://forums.hybridz.org/topic/70734-notchingbevelingbutterfly-l24-block-for-valve-clearance/

-

1973 Rebuild

Profession does not guarantee expertise.

-

Duffy's 1/71 Series 1 240z build

I thought that the very high current was the reason it's not recommended to jump start a car with a completely dead battery. The abnormally high current and subsequent heat can damage the alternator. Not uncommon to lose an alternator after jump-starting a very dead battery. Makes for some of those odd coincidental failure charging system stories.

-

Identify relay

There should be a number on it. Look closely, it might be faded ink.

-

Craigslist Scam

Can you give the CL link?

-

No brake pedal when car running

Although, the part about boredom is on-point. So, thank you for that.

-

No brake pedal when car running

Back to the future...

-

No brake pedal when car running

Good luck.

-

No brake pedal when car running

My mistake.

-

No brake pedal when car running

- ignition wire red/blue

From post #9 - "The guy I bought it from did say he took out the dash and “fixed it” . Did you remove the dash or did you buy a car with the dash removed? Did the car run fine for you or the other guy? Not really clear what's going on.- 78 280 Re-Assembly

You have an odd form versus function dilemma. If function wins then leaving a smooshed steel line is best, I think. Better than a piece of rubber line with hose clamps, isn't it. If you're going for form, then you have to replace the whole thing or use flare fittings to connect the ends of a steel pipe patch piece. Can't see how rubber hose with hose clamps is better than any option. Just conversing. I used compression fittings on my EFI fuel line. That's an option also. Looks clean, and is solid. Doesn't require flaring tools. Got them from McMaster Carr.- 78 280 Re-Assembly

I am going to second CO's proposal, but without even the "smoosh" to make it more round. It's just a vapor line. It might even be the one with a check valve in it, and the check valve is probably the main constriction. Have you checked operation of that pump? If it's original, it's old.- ignition wire red/blue

Good luck with this method.- ignition wire red/blue

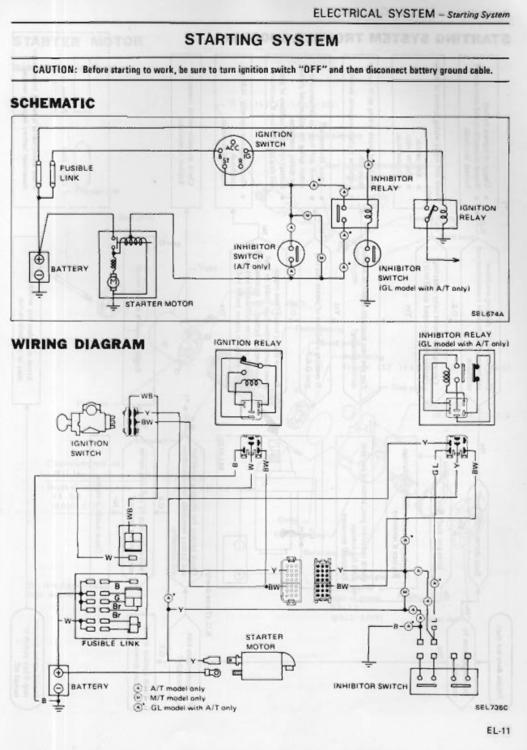

If the engine ran before, and the wire was cut before, then it would not be the problem. Seems like you're focused on something that probably doesn't matter. Do you have a meter? You need to find out where the power is and where the power isn't. The ignition relay is a good starting point. And the fusible link. It supplies the relay, which passes the power on to the harness. With a meter or a test light you can find out where the power is not getting through. This is just one diagram of many in the Electrical chapter. With wire colors. Locations are in another part of the chapter. You just have to get in there and poke around. Don't forget to double-check the battery connections. They can be tight enough to run the meter but loose enough to open up when the starter draws a lot fo current. They need to be tight and clean.- ignition wire red/blue

Did you cut the wire? There is a factory service manual available for free download. https://www.classiczcars.com/files/category/14-280zx/- Removing emissions controls on a 72

Did you actually measure and see this amount of variation or are you talking about the specifications in the FSM? Timing can swing by up to 40 degrees or more with one throttle press, on an engine with common timing controls. The emissions controls typically just affect idle timing. Since you don't drive at idle it won't affect performance.- Where to go with unknown build ive acquired

I'm thinking that you have, basically, an L26 with a bigger than stock valves. Here's an engine calculator to play around with. Looks like about 8.3 CR,which is 280Z L28 range. The head doesn't look shaved, the letters still have a lot of metal under them. http://www.ozdat.com/ozdatonline/enginedesign/ I would check valve lash and the wipe pattern on the rocker arm pads. People make mistakes, or sometimes just throw a bunch of parts together. The N42 head's valves would hit the sides of an L24 bore, unless the bore has been relieved. Might want to turn the engine carefully by hand to be sure there's no interference, before using the starter.- Where to go with unknown build ive acquired

Edit - maybe call that machine shop and see if they have records. The tag has a number. The longer stroke crank started with the L26. So, it could be an L24 stroked out to L26 size. The rebuild tag could be an old one of course, but .030" is a common overbore size. Here are the stock bores and strokes for the three engines. And piston types, as I understand them. L24 83 x 73.7 flat tops L26 83 x 79 dished L28 86 x 79 dished- Where to go with unknown build ive acquired

The original engine size should be stamped on the flat spot above the #6 cylinder, the back one, on the right side of the engine (passenger side in the States). The cam looks like a stock cam, the base circle has not been reduced. The tag from the rebuilder makes it look a like a .030 overbore, so 3 liters seems unlikely. I'm going to guess that it's an L26 that's had an L28 head installed. The L26 had dished pistons, as I understand it. Using the N42 head is probably a simpler way to get bigger valves. The gap between the lash pad and the cam lobe is sign of a loose anti-rattle spring (aka mouse trap spring), I think. Not a huge deal.- L series crank trigger question

Probably just swapped an 81 turbo damper on to his L24. They'll interchange.- 1975 280z getting crushed for scrap metal

I'd rather hit a big soft bug than a small hard one. Who knows what will arrive. Hope they're good. Pilkington is one of the OG glass companies, but, as we all know, brand names get sold, and the quality can get left behind. Let's see. https://en.wikipedia.org/wiki/Pilkington https://www.pilkington.com/en/us- Bringing a 1977 Z back life

Several of us have found that the main problem with the aftermarket or reman hydraulics is that they're dirty inside, with machining swarf/grit left over, that will eat the new seals pretty quickly. Just disassemble and clean them and you'll probably be fine.- L series crank trigger question

Here's one option. You'll probably have to contact him, I can't figure out what, exactly, he's selling. He tends to make good products though. Web-site skills, not so hot. http://hokeperformance.squarespace.com/store/l-series-crank-angle-sensor-kit - ignition wire red/blue

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.