Everything posted by Zed Head

-

Something horrible just happened - an ad autoplayed "music" on the CZCC site

Was not logged in this morning and when I got on the CZCC page awful music started playing. It wasn't obvious that it was CZCC, there was no ad that looked it would be playing music, although there was an ad across the bottom of the page. And it took a short while before the music started. The music stopped when I closed the tab. I don't think that playing awful music when people come across the club site is going to entice people to join up. Just trying to help with new member enrollment.

-

1970 240Z SN 556 on CL in Austin TX Area

-

Barefootdan's 280z Build

This is the question that sanding will answer. Sand it, look at it, make a decision.

-

Barefootdan's 280z Build

I think you're talking about the splined hub. That's just a design feature of the disc. No parts to swap there. You do want to clean the splines on your transmission shaft though and test fit the disc to make sure it slides smoothly on the shaft. It doesn't move far but it does need to be free. Use a wire brush. Check the nose/snout of the transmission front cover also for grooves and wear. The throwout bearing sleeve rides on it and needs a smooth path too. If anybody let a bearing seize up in the past the spinning sleeve can do damage. Some time's the snout/nose breaks off completely.

-

Barefootdan's 280z Build

I don't think that grinding will remove heat checking, it's usually deep. But it might produce a flatter surface. What Monroe was saying, I think, is if looks good AFTER scuffing/sanding/smoothing then it's good to go. I've done it and it worked fine. You can put a piece of sandpaper on a flat hard block and sand the surface. You'll probably be able to tell if the surface produced is flat and consistent when you're done. Fun to do even if you decide to have it ground anyway.

-

1976 280Z Restoration Project

Just read a story about a young guy who got killed when he was ejected from his car while doing doughnuts. It rolled, he got thrown, the truck landed on him. It only takes one mistake. Forgot to say - he didn't have his seat belt fastened. The primary safety feature for car crash safety.

-

Advice on replacing fuel lines to a '75 280 Z

These are made for vacuum, pull-through, applications. Furnace oil. Kind of kidding but if you needed something to get you by until you could fix the tank, they'll hold a lot of crud and don't hinder flow. Put a ball valve in front and it's easy maintenance. https://www.amazon.com/General-Filter-1A-25B-Standard-8-Inch/

-

1970 240z electric fuel pump question

Wrong year.

-

1970 240z electric fuel pump question

Got my threads mixed up. Posting 71 info in a 70 thread that has been converted to 73. Never mind.

-

Need Help Finding a Harmonic Balancer with an AC Pulley Groove or Finding a Pulley Addon for my Current Balancer

Here's a recent post about the Z and ZX damper pulleys. Never thought about it until now but if the pulley is bigger it will raise the alternator speed, helping the low voltage at idle problem that a lot of Z's have. Maybe everyone should switch to a ZX pulley.

-

Need Help Finding a Harmonic Balancer with an AC Pulley Groove or Finding a Pulley Addon for my Current Balancer

I think that the dampers are a different size and you'd need a timing marker to match but a ZX damper and pulleys might be easier to find and might be workable. And, another vague memory, I think that some of the AC pulleys were removable. So your thought of bolting one on should work if you can find one and the holes are there.

-

Ignition switch

If you try the things suggested and decide that you need that part then breaking/filing off the extra ear should be fine. Still interesting that you have a one-eared switch. Probably works just like the two-eared.

-

Ignition switch

Have you tried working it with a screwdriver while it's open? Sometimes it's the mechanical part not the electrical switch. I've never seen a one-eared switch. Wonder if there are other differences you need to consider.

-

1970 240z electric fuel pump question

To jump a circuit just means to connect two things, in electrical terms. A jumper wire is the wire used to connect two points in a circuit. So when w3 says just jumper the blue taped connector he means connect it to some other point. Probably a power source. I don't know, exactly, what to jump it to either, but, apparently, the wire that heads back to the pump area is in that blue taped bundle. All these words and just a fraction closer. Might as well find that naugahyde wrapped blue taped bundle. You'll be even closer.

-

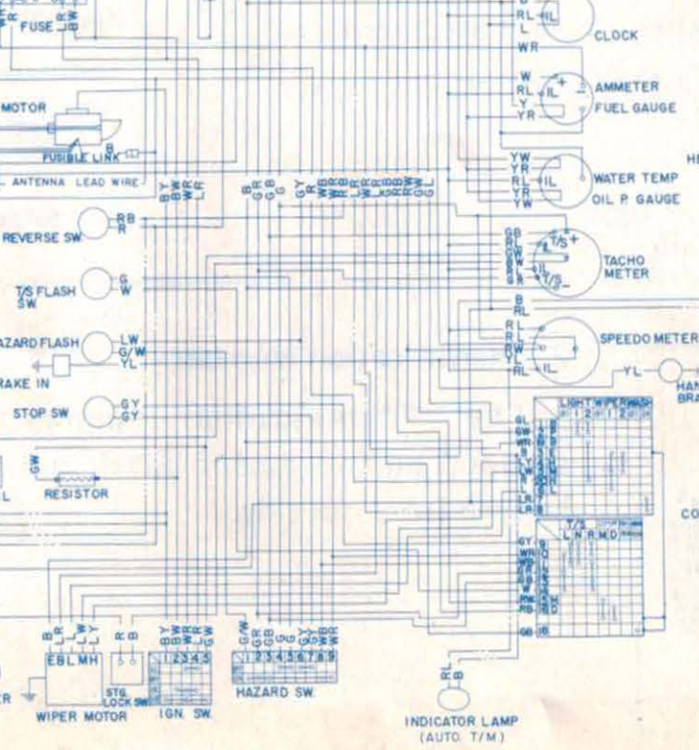

1971 240Z Tachometer Wiring Problem

I almost added something about the Owners Manual but didn't. Didn't want to get too wordy and thought the FSM might have it. That's where the full diagrams are for some reason. Page 37. Edit - actually I didn't post the link to the diagram because he's looking for the actual harness connections. Best to just stick your head up under the dash and poke and pull and follow. https://www.classiczcars.com/files/category/17-owner-manuals/

-

1971 240Z Tachometer Wiring Problem

You might find something in the Electrical chapter of the FSM. https://www.classiczcars.com/files/category/9-factory-service-manuals/

-

Engine Timing Cover

The first one looks safer, a smoother transition to the guide. You might catch that edge with the second setup. That is the loose side, with the crankshaft pushing the chain off the sprocket. It only sees the tension of the oil pressure powered tensioner, and the inertia of the moving chain. It doesn't get pulled straight like the drive side. In the first setup if you took your finger and pushed on that kinked link would it push inward and make a smoother curve? That's what it's going to do when the engine is running. Plus you'll get some wear immediately on the chain and the guides that will change things.

-

Engine block tilt

You could have leveled the bottom of the oil pan and used your angle gauge on the top of the head or block. Or leveled the top of the head and put your angle gauge on the bottom of the oil pan. Actually, you can still do that. Anyway. Why do you need the angle?

-

Engine block tilt

Just realized that you can get the angle from the oil pan also. The bottom ends up parallel with the floor of the ground. Assuming a perfect world.

-

Engine block tilt

Here's a picture.

-

Window roller

Might work but it will leave a streak on his window, then dry up pretty quickly. Plus, any water that runs by will absorb the fluid and carry it away. Works on tires though.

-

Black liquid out exhaust.

All engines tend to run rich when cold, and the engines without O2 sensors tend to run richer because there's no feedback to the ECU to make things as lean as possible. And that's why your car has a floor temperature warning light. Converters get hot when they see too much unburned fuel. It's always going to spit black water when the engine is cold. Put a piece of carpet back there to collect the drips. It's normal.

-

73' 240z ballast resistor removal

Can't really find a place to put "loose wire" and make sense. Re-read the thread tomorrow after some sleep and see what you get out of it. "So it has to be a ground "loose wire" somewhere not sending the proper output to the coil. "? Still doesn't work. Loose wires don't send outputs either.

-

73' 240z ballast resistor removal

The wires are already connected. They attach to the same piece of metal. Nissan used the ballast resistor as a convenient place to create a terminal block.

-

73' 240z ballast resistor removal

You write very confidently, but the statement makes no sense. Grounds don't send outputs. And the video was neat but no idea what it was meant to show. I saw a good spark. The engine sounded pretty smooth for 5 cylinders. Lots of other things can affect individual cylinders. Valve lash, valve sealing quality, compression, bad plug wires... Good luck.