Everything posted by zKars

-

Help finding a 240Z Electric Fuel Pump bracket

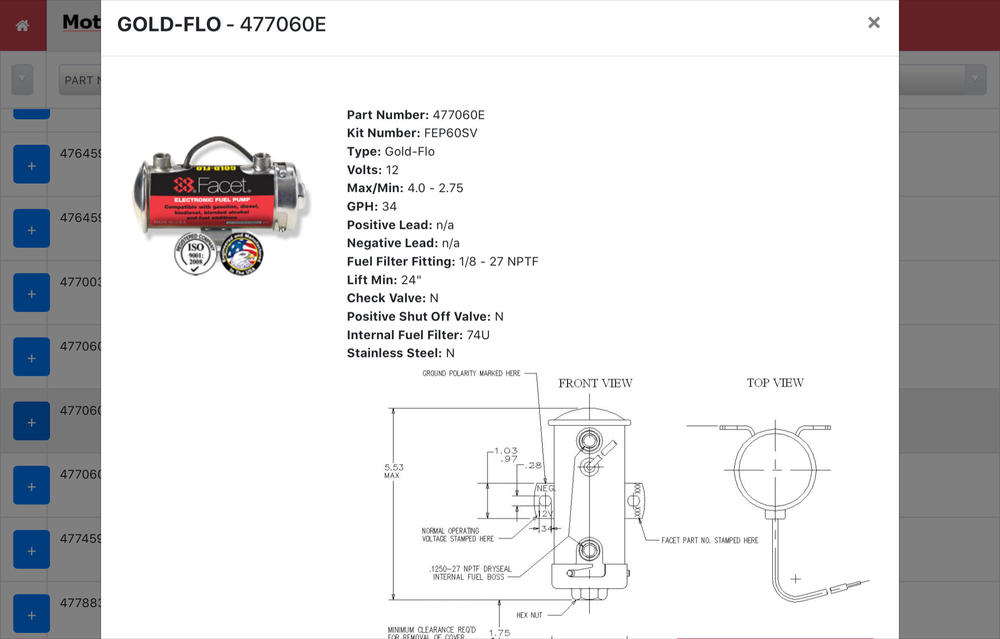

My favorite “in between the Nismo and Airtex” price point and functionality is the Facet FEP60SV or 477060E. Same form factor as the Original and Nismo, internal easy to change filter too. The best price is actually from aircraftspruce.com or or .ca Installed several for friends and myself, never had one fail. My two cents for the day

-

Nice Brochure

They say don’t covet thy neighbors wife, well I’m coveting thy Z buddy’s paper goodies! Those brochures are the bomb! Nice bit of trading. Now I’m feeling really sad about not being on that little jaunt with the BC gang recently.

-

240Z blue interior paint

found my can of blue. it does not have a mix code. just says "SEM 5312 adjusted" Great.... some base then he fiddled until it matched my sample

-

240Z blue interior paint

I think i had my body shop supply create a custom mix. It looked perfect to the MSA seat covers I bought. I’ll see if I can find a partial can left, it might have the formula. I’m a huge fan of butterscotch interior on dark green cars, but when I did this pure white with blue interior it was love at first sight.

-

Aluminum Rad Repair. Alternative method

Now clearly I have nothing to say about lifetime of the repair. That will be seen. I have another aluminum rad from my 510 that was damaged by galvanic action. I had the electric fans grounded to the rad body, which I assumed lead to the problem. I think we discussed this before. A small portion of the bottom tank right beside the base of a few fins, like 2 inches long, 1/4 wide now leaks right through the fabric of the aluminum. You could put some water in, pressure it up with air and watch the water seep through the “solid” tank. Pretty cool if it weren’t so sad. Didn’t know how to repair that before, but now I do. Coat it with a thin film of this stuff. As with most things, if you are brave enough to try this, the repair area must be surgically clean before application. Their instructions to lightly sandblast is a great way to accomplish this. At the very least degrease then scrub with a stainless steel brush.

-

Aluminum Rad Repair. Alternative method

I’ll let the pictures do the talking. Note: The story of how the hole happened is fictitious, but thought representative of the situation. I will never reveal how these holes were created in my customer’s rad.... The one hole is obvious, the one to the left also has a tiny hole in the bend in the tube. Found that during the wet pressure test. Here is the repair all done. Took literally 4 minutes until I was ready to pressure test. And here is the magic product. STIC-TITE hot melt plastic aluminum repair rod.

-

Aluminum Rad Repair. Alternative method

So you put that big shiny Ebay Aluminum rad in your Z, and you go out to test it on a really hot day. You’ve been having problems keeping the beast cool and you’re sure this massive shiny 3 core magical heat exchanger will solve all your problems. Everything is fine, until a gravel truck in front of you starts spewing loads of nice sharp little rocks at you and your nice new shiny rad. Soon you start smelling the telltale odor of sickly sweet anti freeze and the soon to follow cloud of steam ensues. Oh crap.... You get it home, rip that POS out and put your old brass stocker rad back in until you get this thing fixed. Now who fixes aluminum rads these days? You call around, you find a couple of shops, quotes are in the hundreds of dollars. You remind yourself that you could have soldered up a brass rad yourself for $1.50. Oh crap. Out comes the browsing device and a torrent of googling ensues. You see many links for aluminum brazing rods that make it seem like a child’s game. Heat it up, dab on some the magic alloy and your rad is sealed. You spend $50 bucks, wait a couple of days for it to show, then get to work. You clean, you prep, you heat, you apply, ooooohhh it flows so nice, you let it cool, you Put some water in it and pressurize it, (oh you bought a rad pressure test kit too, another $75) and..... You get squirted in the face with a fine stream of high pressure water from around the lovely dollop of shiny aluminum rod. And two other holes nearby show up too. Try again, clean better, add more heat, more rod, more mess. Guess what happens. Yup, wet shirt this time. Then you go back to google. And you find an innovative product. You buy some it and it works like a charm. You are amazed. It cost $17 CAD. You are happy and fulfilled. I suppose I should share what it is..

-

1970 240Z my personal dream car – project TOSBO

Check the tightness of the nuts on the diff studs through the mustache bar as a possible source of drive clunk.

-

Weakness Revealed in the GMB and Spectra Mechanic Fuel pumps

Ah the wonders of Rock Auto. My three GMB fuel pumps came in today already. (ordered Monday, Fed Ex cheap delivery) I am sad to report that the top caps on all three of these were assembled correctly. So what can we learn from this. Is it only Spectra pumps that have these issues? Was the one incorrectly assembled Spectra I encountered a total one off? I sent the customer home this morning with his Spectra working flawlessly and instructions on how to pop the fuse back in the new electric pump circuit when (and if) it fails. It seems we are back to check valve shaming for the time being.

-

Weakness Revealed in the GMB and Spectra Mechanic Fuel pumps

It may very well be that my one example of the cap on 90 degrees out is a total one-off anomaly and the real culprit is the check valves as I initially expected. More evidence to gather for sure. Keep them cards and letters coming.

-

Weakness Revealed in the GMB and Spectra Mechanic Fuel pumps

That’s excellent feedback. Good to know that check valves are a problem too. \Sorry I mistook it for an OEM. I’ve never dug one out of the body. With those stamped in valves, how did you get it stay in after you removed it?

-

Clutch Max clutches!

Exedy has yet to disappoint. Definitely my goto.

-

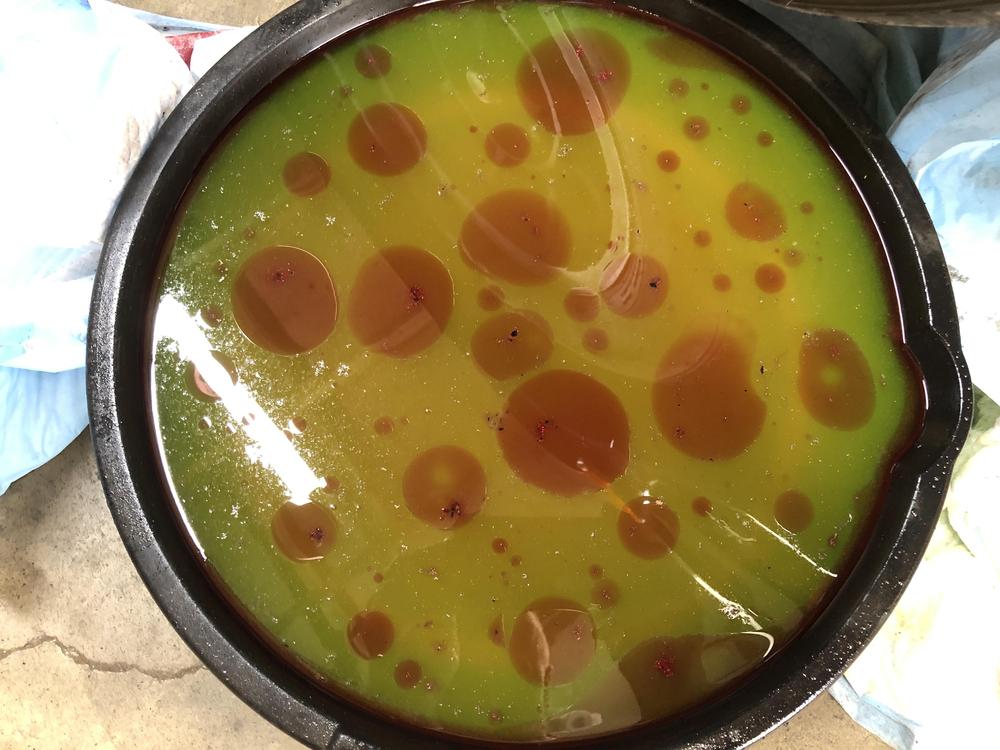

Fun post for Tuesday

Well glad we had some fun. Thanks for the contributions. It was just antifreeze and ATF. I hoped the relative rarity of automatics in Z’s might make this a bit more of a puzzle. It was the first auto equipped Z I’ve actually done more work on then just yank the auto trans and recycle it. Spent a fair amount of time swapping rad’s in this late 71. This involved the joy of removing and replacing the auto cooler lines so the inevitable dribbling of ATF into my coolant recovery tray resulted. The pattern was interesting and a bit artsy so I had to take a couple of pics. Learned alot about the thread specs on the stock hard lines and the rad fittings. AN dash 6 thread on the rad was interesting realization. The hard lines and soft lines are a very curious mix of metric fittings. The hard lines are 5/16 or 8mm. Glad no one went to the blood and coolant guess..... yuch.....

-

Weakness Revealed in the GMB and Spectra Mechanic Fuel pumps

That’s something I haven’t seen before. That’s an OEM check valve isn’t it? If you poke the valve disk, can you get that disk to reseat or is it deformed and stuck like that?

-

Weakness Revealed in the GMB and Spectra Mechanic Fuel pumps

Was there reason to believe it was giving problems before? Is it new?

-

Weakness Revealed in the GMB and Spectra Mechanic Fuel pumps

Just for grins, I checked a new equivalent Spectra pump for a 510 that I have in stock. Popped it’s cap and it’s assembled right. I just put an electric pump in this Z, so I’m going to get the owner to run it with the fuse pulled for as long as he can stand it, and let the “fixed” mechanical run and see if it quits again. Easy to get back on the road if it does with a simple fuse insertion. At this point, knowing this pump can run at full pressure and flowrate after having failed, the only other failure mode might be heat related where maybe the check valve flaps stop sealing well after a period of time, then re-form and work again after they cool off?? The main diaphragm is just fine,

-

Weakness Revealed in the GMB and Spectra Mechanic Fuel pumps

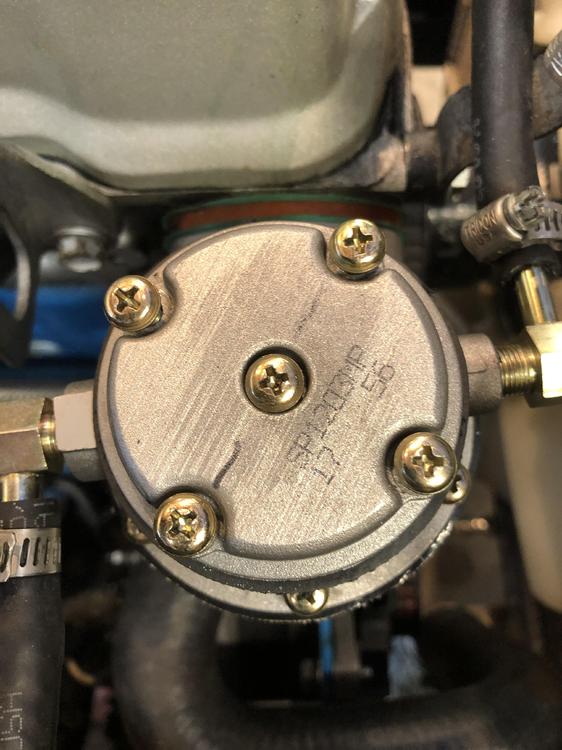

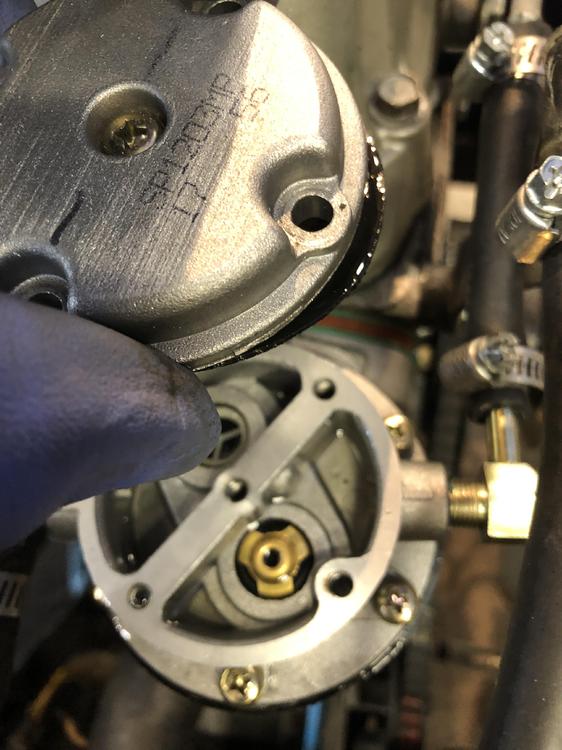

Here are a couple of pics “under the hood” so to speak on the Spectra pump I’m testing. Here is the internal divider wall between the intake and output check and here is the cap showing its internal divider wall in line with the lower one. When I first opened it the cap was 90 deg out. I tried putting the cap back on “wrong” this morning to see if I could get it to run for a while then quit, but no such luck. Pump output, as seen by taking a hose off the carb, was 0, nadda, szilch. Switch it back and boom, perfect working pump.

-

Fun post for Tuesday

Identify the fluids in the bowl and win a prize. Speculate on how they came to be together and gain additional notoriety. Explain the reason the red stuff forms nice circles in the middle and a thin film around the edge for even more points.

-

ISO 280Z damper bracket

https://www.facebook.com/groups/1822782428004038/permalink/2836027283346209/?sale_post_id=2836027283346209 Guy names Chris Myers has a box with fuel pump goodies including the elusive bracket for sale

-

Weakness Revealed in the GMB and Spectra Mechanic Fuel pumps

Ok, what I think the issue is that the top cap is installed at the factory 90 degrees wrong, The internal center rib on the cap MUST be aligned with the mating center rib between the two check valves. Having the cap on with the ribs crossed allows flow to sneak through that upper diaphragm. This was the case with the one I looked at today. Turned the cap 90 and put it back on, and boom. Perfectly functioning pump. I wanted others with failed pumps to take the top off and see if the factory has the ribs aligned or crossed. My guess is that from the factory, the diaphragm is sticky enough in some way to limit the leak, but eventually and quickly the dam bursts and that’s it No more suction. At least that’s today’s theory. I need someone else to find the same flaw. Secretly I ordered three more GMB pumps from RockAuto today (can’t beat $17.83 CAD each!) to see if any or all have the flaw. Is it random or is the assembly line guy/robot slapping them together. however they like?

-

Weakness Revealed in the GMB and Spectra Mechanic Fuel pumps

Ok, I have a clue! Highly unexpected, but true. What I need is someone with a failed Spectra or GMB mechanical pump that is willing to take the top cap off and tell me what they see. Don’t take it off without marking it’s position relative to the body first!! Very Important!!!! Anybody?

-

Weakness Revealed in the GMB and Spectra Mechanic Fuel pumps

Pictures are back.

-

Weakness Revealed in the GMB and Spectra Mechanic Fuel pumps

The pictures are on my phone somewhere. I'll do more to spruce up the thread when I find out details on this pump tomorrow I was doing a bit of research again on what's out there, and wanted to share the current status of what RockAuto sells. The GMB, US Motor Works and Delphi are shown as having the OEM look, but look at that price difference! GMB is free is $18 buck, where as the USMP is $72!! Maybe it has quality innards. yeah, right.....

-

Weakness Revealed in the GMB and Spectra Mechanic Fuel pumps

I have another case reported today from a local customer with a <100 km use new Spectra pump that failed. Fortunately it was initial warm up in his garage, not on the road, but that was just pure luck. He was on his way to a wedding (not his at least) but was anxious to show it off to family members. Very disappointing. I'll have that rotten pump and the Z in my shop tomorrow. I will thoroughly diagnose the issue with the pump and let you know what I find.

-

ISO 280Z damper bracket

Somewhere, somewhere......

Subscriber

Subscriber