Everything posted by zKars

-

Parts Wanted: Hitachi TM-1081ZB - AM Radio

I have one as well @GoldAir

-

Period Correct Tires

Have a local here the Vred’s on his 73. They look great and handle well.

-

Machine work on SU for roller bearings

Not sure if this has been discussed above (to lazy to read every word (but not too lazy to type endlessly here…)) but is the usual “leak” caused by bearing wear or shaft wear or both? Just replacing the bearing is fine, but how are we building the shafts back up to 10mm? Or is the fact that the new bearing have seals now, that these seals now rub on what’s left of the shaft, and maybe at the very edge of where the old bushing touched it which might be still mostly 10mm, effectively sealing it? Which begs the question, are new shafts and butterflies available anymore?

-

Machine work on SU for roller bearings

McMaster will ship to me, they do it all the time. I just have to be registered as a business. They won’t ship internationally without that check box being ticked. Thanks!

-

Need a stock front valance

Here are my pictures. There are some welding repairs on the two outer “wings” to account for poor factory assembly. These are raw and only primered, some body work is expected.

-

Need a stock front valance

Sure do. Let me find them and post a picture

-

Need a stock front valance

I have a brand new after market set. I can dig them out for you. No idea what manufacturer they came from.

- Which Oil Pan Will Fit?

-

Machine work on SU for roller bearings

Anyone brave enough to reveal a source for said 10mm ID sealed bearings?

-

Has anyone tried these extended headlight buckets for LEDs?

When dapper was first selling their LED bulbs and housings, I bought a pair. The size of the bulb backing (I think it had a fan!) and its ballast box DID NOT FIT in the stock housing. I made a bulge using a ball peen hammer to make them fit, trial and error. No fun. The lights are amazing I have to say. As mentioned above, there are LED bulbs for generic H4 housings available now that fit just fine in the stock cans, so Dapper is just covering there products to ensure they fit in S30’s. Still, it’s nice to have a source for replacement housings, which even come with new aiming screws.

-

Knock sensor band pass filter

https://www.viatrack.ca/

-

Knock sensor band pass filter

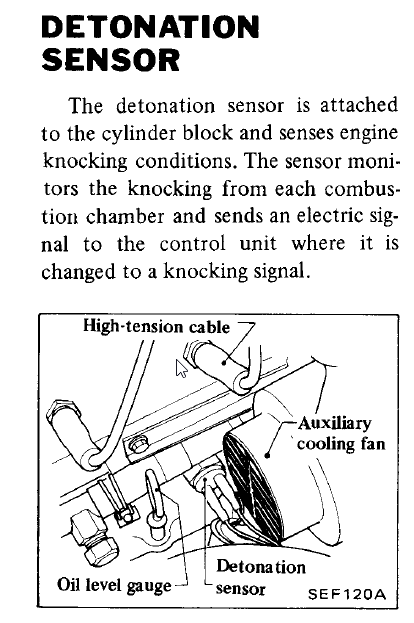

https://phormula.com/knock-frequency-calculator/?fbclid=IwAR1dO8_Qw8lferQVBmn7h66PiqEi3_FtGA5hvaXtLDI-7r5ed6ihA8VfxeI All of the aftermarket ECU vendors (Haltech, MegaSquirt, etc) that support knock sensor inputs have some documentation related to the subject. At least you can see the input screens and review what types of inputs are needed. It’s all about finding the frequency band where knock occurs on your engine. And mechanically about putting the sensor where it can pick up the noise properly. Engines that never had knock sensors don’t have convenient places to mount one in the “right” place. You have to get creative sometimes. You can’t just duct tape to the side of the block. The only knock sensor on an L series is on the 82-83 ZXT in the block just below the head.

-

water pump 280z

Comments pertain to simple water tight areas Flat clean even surfaces, new gaskets, proper bolt torque = no leaks. What the heck you think rtv in there is gonna do? LEAVE when you tighten it down is what it’s going to do. WHY?!?!?!?! Old cars, less than even flat surfaces (gotta stop using a razor blade to scrap with, sheesh…), LITTLE RTV ain’t gonna hurt. Any excess gets squeezed out. Gasket won’t stay in place while you put the (fill in the blank), add some adhesive glue stuff to stick it there. Ain’t no downside to a LITTLE. Gobs of squeeze out on the inside is your only danger. L I T T L E people! (Apolgies to the vertically challenged.)

-

Squeaky Clutch Pedal and Clevis Pin

Right. Ball

-

Squeaky Clutch Pedal and Clevis Pin

All I seem to remember was I used a bearing intended for a router bit guide and spot welded it to the pedal metal more or less centered in the hole I drilled to hold the bearing. Since then I’ve just welded up such worn holes and re=drilled the 8mm or 5/16 hole. Good for another 50 years I’d think. I mean a press fit of the bearing might be good enough too, it’s trapped by the brake/clutch fork where the pin goes through if it does come loose.

-

SU flat top bowl drain screw

https://www.carpartsmanual.com/datsun/Z-1969-1978/engine-240z-260z/carburetor-240z-(l24)/from-jul-72#1 It’s part #40, good luck finding it…..

-

Impossible Oil Leak?

-

Impossible Oil Leak?

My collection of caps (4 kinds), indicates that all the ones that say simple “OIL” require no gasket on the cap, and fit valve covers that require O-rings in the provided groove around the fill opening on the cover. All others, Elephant or otherwise, use the stepped flat o-ring gasket discussed above. A few of mine had that gasket inverted. One had two gaskets, all had at least one. Most were quite hard, though none were rock hard. None were dry split or deteriorated to the point of obvious leakyness. I only included pictures of OIL cap and it’s back side showing no groove like all the others that take the step gasket.

-

Testing Pertronix Ignition Module

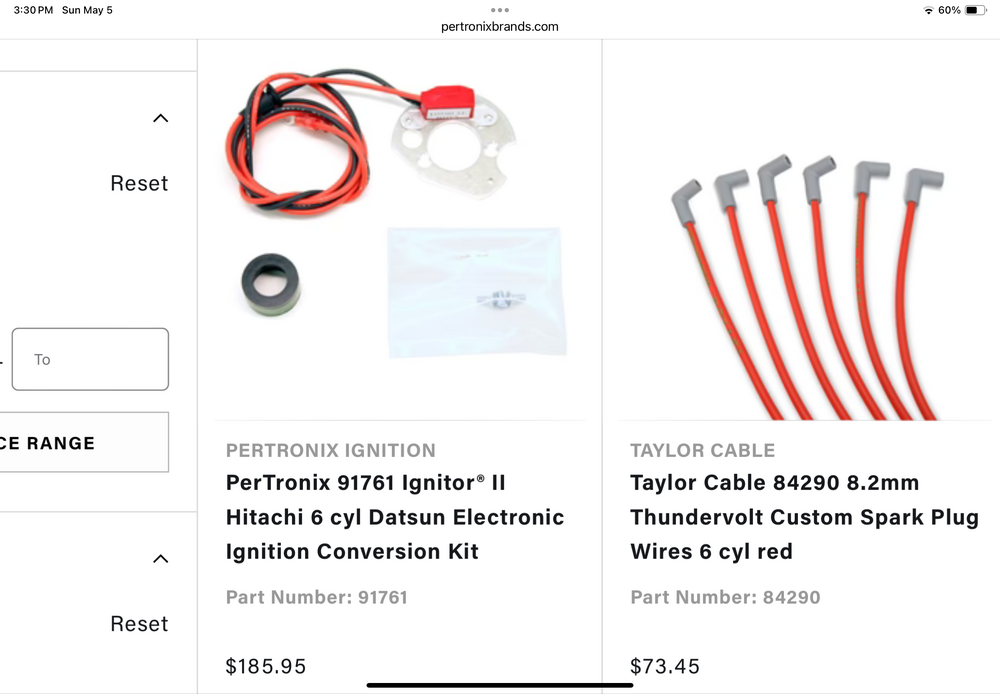

I heard the rumor once that the “old” or initial Pertronix are prone to the burn out if left on issue, but the later models don’t have that problem. Pertronix I vs II. Searching I see lots of references to I vs II comparisons, but not Datsun 1761 related. Pertronix web site does however list a “II” for 240z. PN 91761. 1761 is the old version one. So I suggest we get the 9 version from now on. $185 vs $135 of course There is also the L4 equivalent, 91761 vs 1741. They also list replacement modules for both in case it does blow up so you don’t have to buy a whole new kit.

-

73 240 No spark

Basics basics basics. You’ve checked the power to the + side of the coil. Good. Do the points open and close as the dizzy rotates? Are the contacts clean? Bit of sand paper in there dragged through to scuff them a bit. There is a gap spec, 0.018 or so? The terminal that connects to the dizzy that connects to the points. Is it dirty? Does it fit snug? Put it on and off a few times to scrape it clean, Start there, report back

-

Center console repair 280z

Plastic repair is one of those things I’ve been experimenting with frequently in the last year or so. The usual, interior plastic panels, consoles yes, broken eye glass frames, toy repair, you name it. These are my favorite findings and tools 1. Plastic welding. Basically a wide flat soldering iron with filler “wire” of various plastic species. Melt the substrate, add filler, smear it all over. 2. Wire staples in various shapes, that you heat up and press across a crack that melt then harden into the plastic thickness, binding the two sides together. 3. Build up missing areas with UV cure epoxy resin. This is my new favorite. Also makes a good glue for plastics. Used to buy in small expensive gluing kits (Goggle Bondic) but now UV cure resins are everywhere in the hobby world and are cheap.

-

No Brake Lights or Turn Signals. Where to look next?

Turn signal light issues, especially those that exist while the hazards work just fine, are often the fault of the hazard switch. Remove it and clean its internal contacts and check for solder problems where the wires attach. Also make sure the battery is fully charged or the car is running, or attach a charger to the battery while you do testing. Low voltage often causes older flasher units to not want to do their job well or at all making diagnosis of related problems difficult.

-

1st Drive 2024

The two hole pump is for L16/18/20. Four banger. Great donor for internal parts. I once bought a Toyota fuel pump that was also an organ donor. I suspect that design was used on many Japanese cars in the day

-

Factory panel bond?

It’s the black goo that that leaks out and spoils the weld when you’re installing over fender flairs and have cut out the wheel well lip, then weld the two layers back together, or try to at least. It’s a caulking, not a bonding agent. Maybe some fear of water getting in the air vent holes and getting down in that area.

-

Cruise Control in 240Z

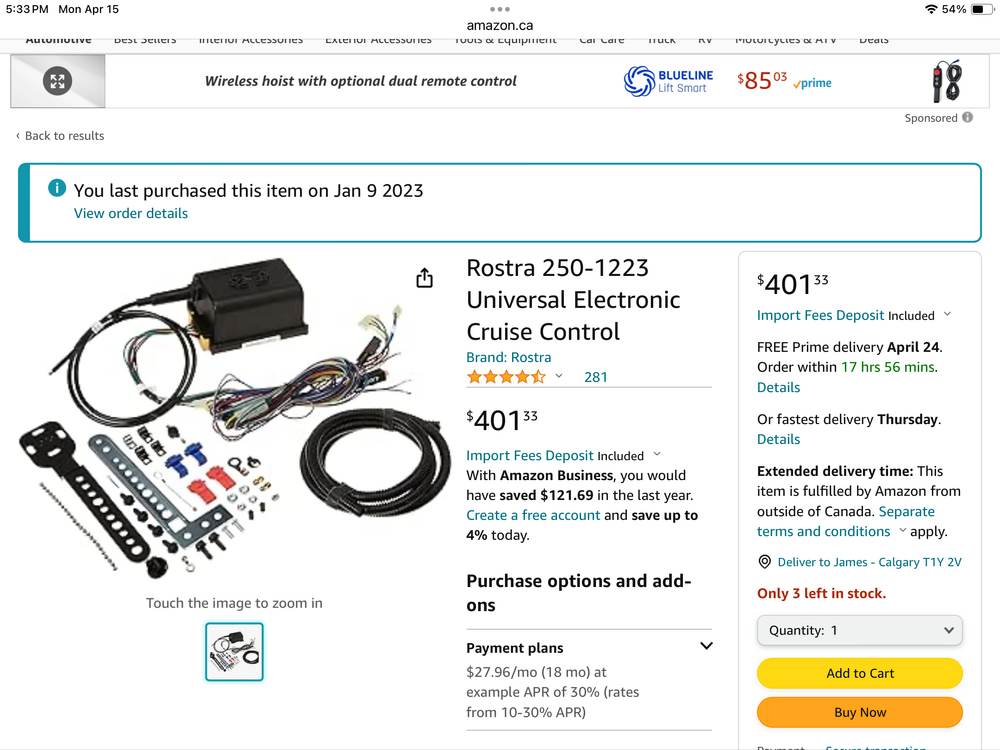

Rostra seems to have the only commercial consumer cruise control system. Pic below of what I got recently from Amazon. Just need a speed digital signal. There is a couple of options, you can splice a “thing” (I’ll find a link eventually) into your speedo cable, or if you have a GPS speedo, then do away with the cable all together and use this. https://protunerz.com/collections/sensors/products/mechanical-to-electrical-vss-metric-with-connector Now the hot tip is as Duffy says, go Drive by Wire and let your aftermarket ECU handle the cruise control duties. And idle control, etc. Its just a big step. There are actuators for triple carbs or throttle bodies too. See what efihardware in Australia has. Cool stuff https://www.efihardware.com/products/c598/dbw-components I have seen a few folks working on nice solutions with 350Z throttle bodies and pedals, what are you doing Duffy?

Subscriber

Subscriber