Today, I finished reassembly and testing of the horns. I made some gaskets out of some old "resume" paper I had. It is high quality paper in a slightly off white color. I sprayed a couple of coats of clear coat from a spray can on each side of the new gasket.

The differential side flange shim was a good template for the ID. I used the horn for the OD.

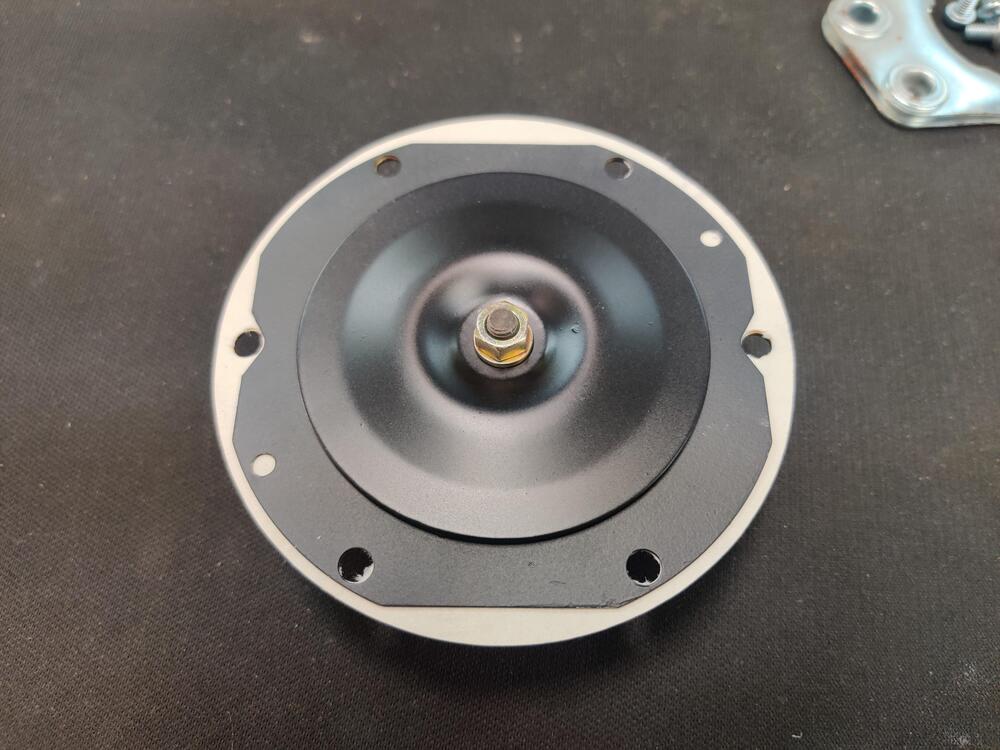

Some people have said that their horns have a very dark brown finish on the front. Some have said they were other colors. Mine sure looked to be black to me.

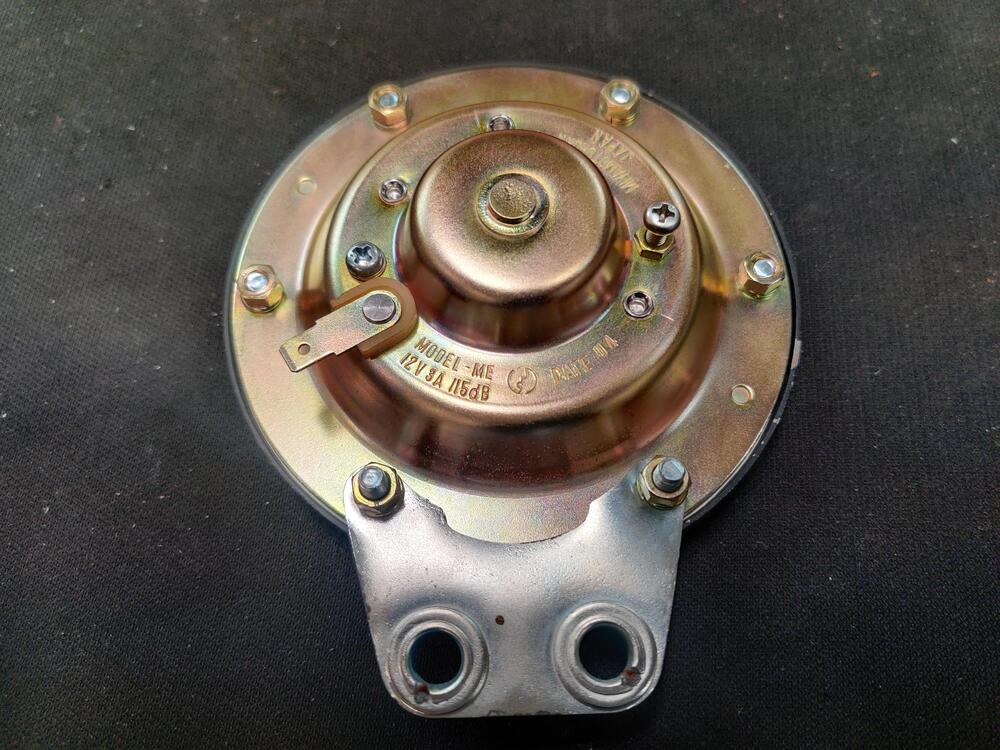

Condition the horn was in when I took it apart.

This plate is aluminum and was painted black on one side. That paint looked to be done at the factory to me.

I cleaned it and resprayed it with Krylon semi-flat black.

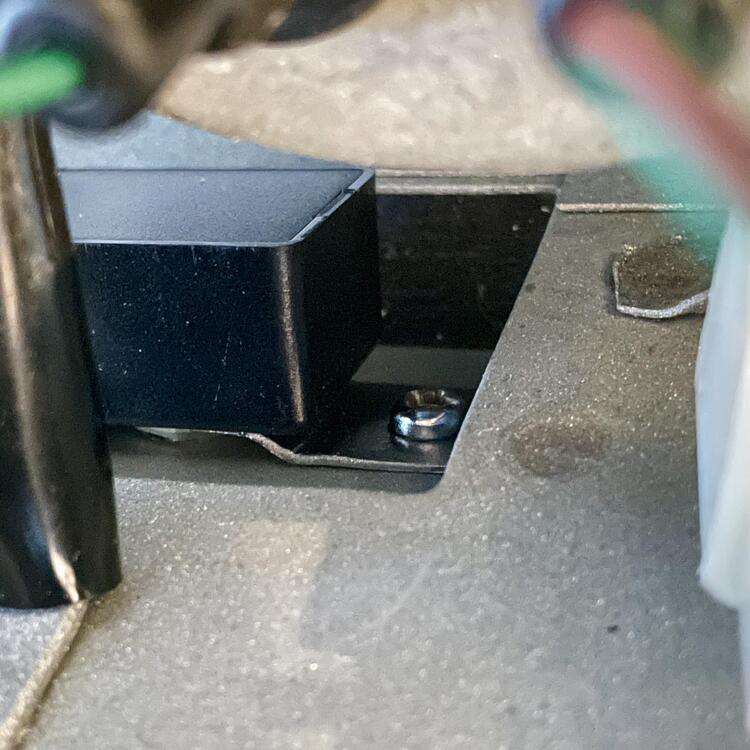

I forgot to take a picture of all the hardware, but here is some of it. The mounting bracket has two little aluminum spacers that go in between the plates. Two longer 6 mm screws secure the mounting bracket to the horn. The other four 6 mm screws are much shorter.

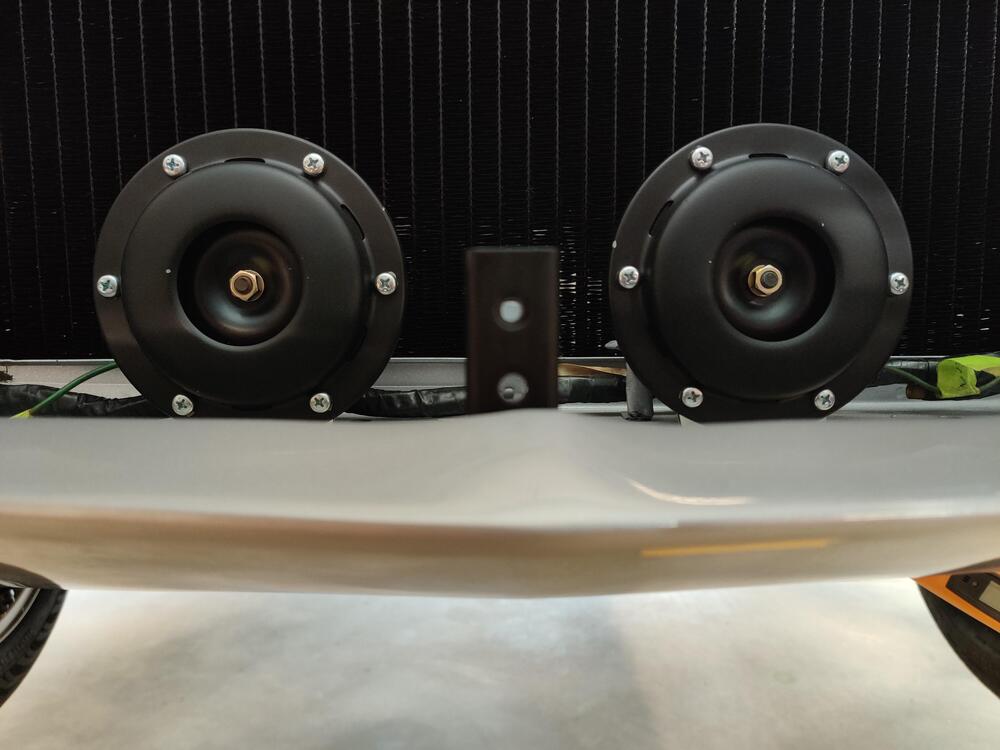

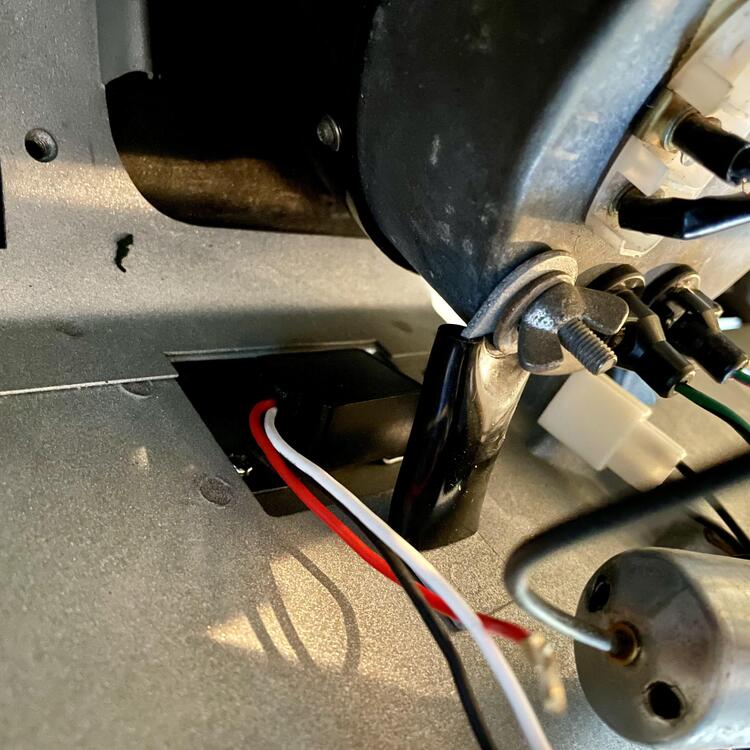

Horns installed.

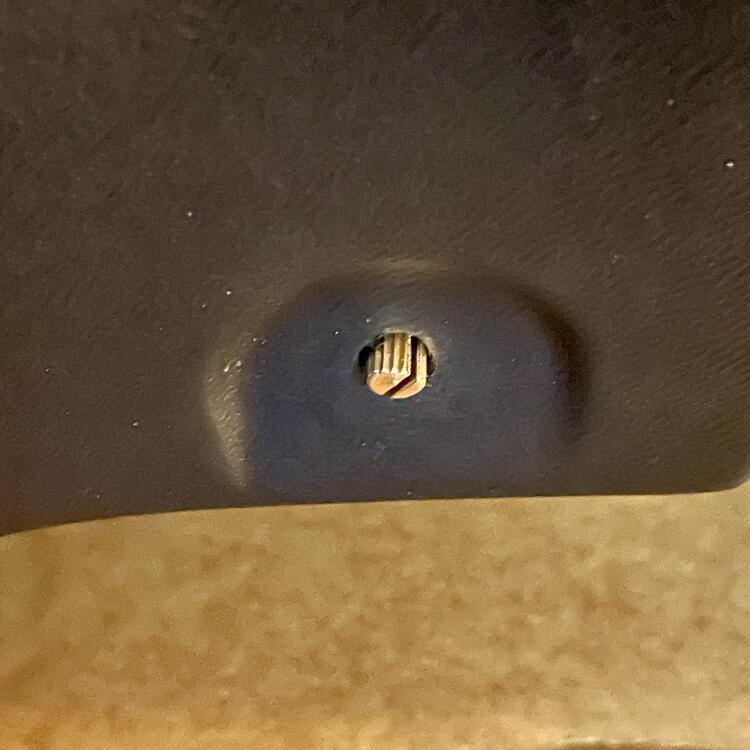

It is interesting what makes the horns high vs. low pitch. I think all of the parts are the same except perhaps the piece to the far left in this picture.

I think the height of it is different for each horn. And to get the contacts operating properly, the volume adjustment screws have to be set differently for each. I found this out by having to adjust my volume screws differently from what I did yesterday. The screw that was tall, I had to make short. And the screw that was short, I had to make tall.

It was an interesting learning experience, but now they are both adjusted and nice and loud.

Subscriber

Subscriber 3Points1,282Posts

3Points1,282Posts