Plastic repair is one of those things I’ve been experimenting with frequently in the last year or so. The usual, interior plastic panels, consoles yes, broken eye glass frames, toy repair, you name it.

These are my favorite findings and tools

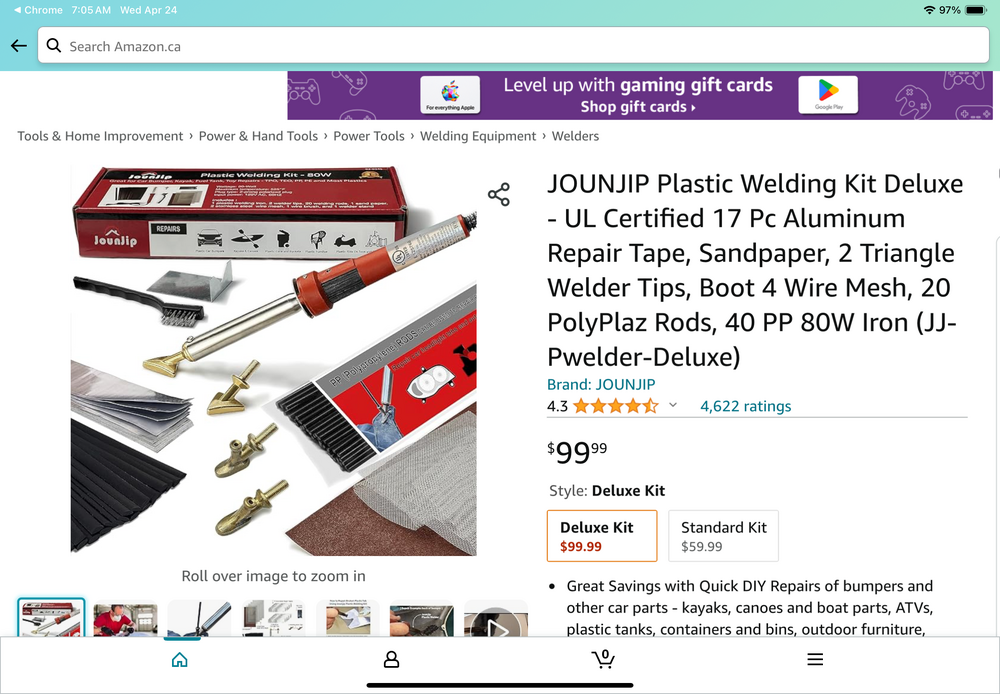

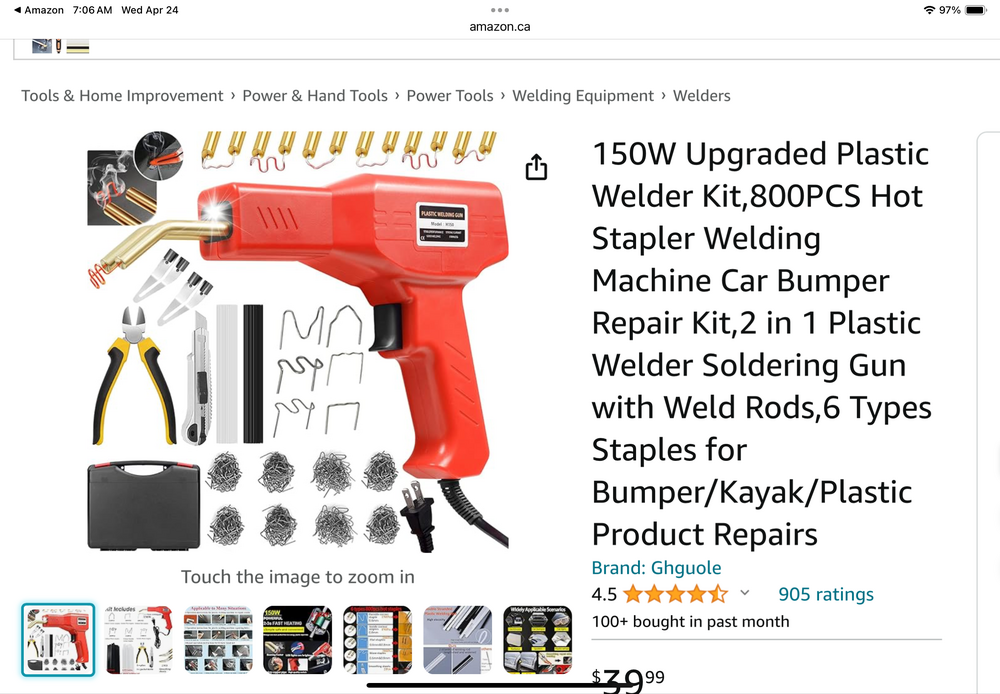

1. Plastic welding. Basically a wide flat soldering iron with filler “wire” of various plastic species. Melt the substrate, add filler, smear it all over.

2. Wire staples in various shapes, that you heat up and press across a crack that melt then harden into the plastic thickness, binding the two sides together.

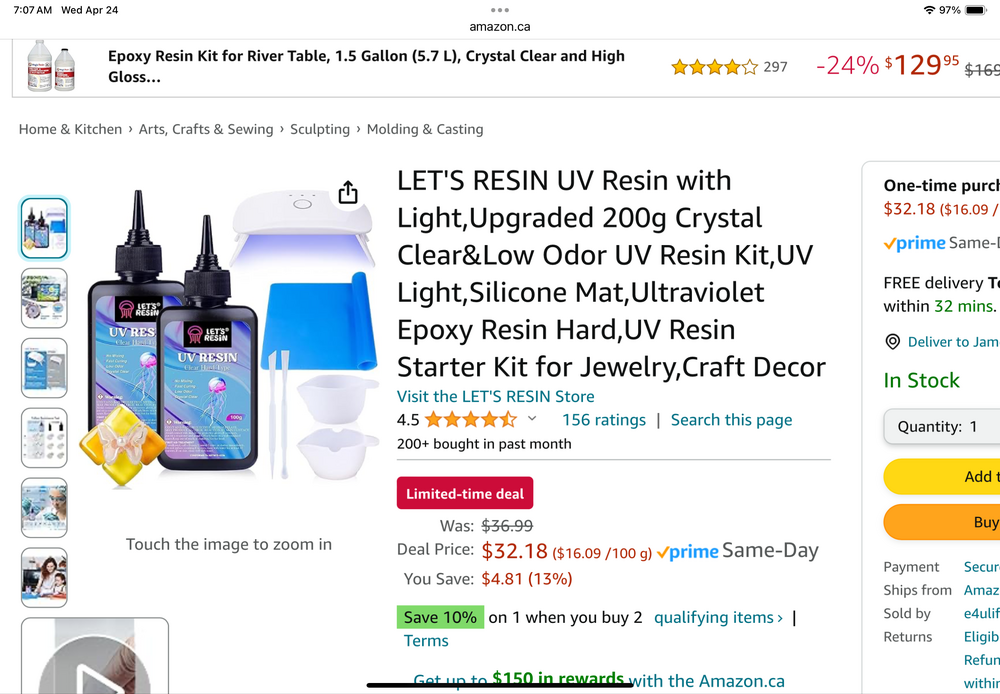

3. Build up missing areas with UV cure epoxy resin. This is my new favorite. Also makes a good glue for plastics. Used to buy in small expensive gluing kits (Goggle Bondic) but now UV cure resins are everywhere in the hobby world and are cheap.

Subscriber

Subscriber 1Points11,142Posts

1Points11,142Posts