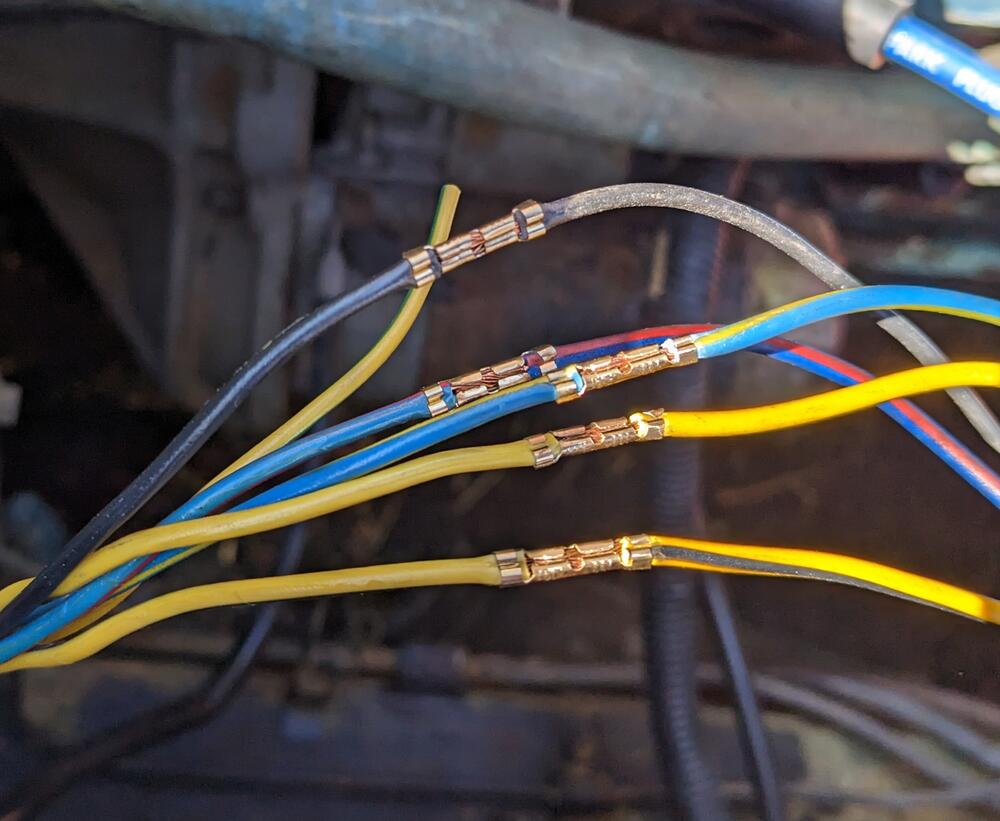

Got the bracket & motor back in the cowl, and rewired for the Honda Motor. I found that one hand can be fit behind the bracket from the right side to get the linkage arm nut back on the wiper motor. I decided to cut off the Datsun connector as those small pins just seem iffy for the load of the wiper motor, given their antiquity. I added lengths of same color wire to extend the stock harness through the cowl, used a Volvo firewall grommet, and then added the Honda (Yazaki 58XS) connector and female pins.

BLK, BLU-R, Y,Y-BLK, BLU-Y. Y-G is unused.

Solder joints are a bad idea - so I bought a large number of crimp splices some time back. Color-keyed wiring came from my old 80's X1/9 parts car. I removed the entire dash harness before junking it.

double shrink wrapped

I noticed that there is extra weather-strip glue under the seal - I'll have to get that off

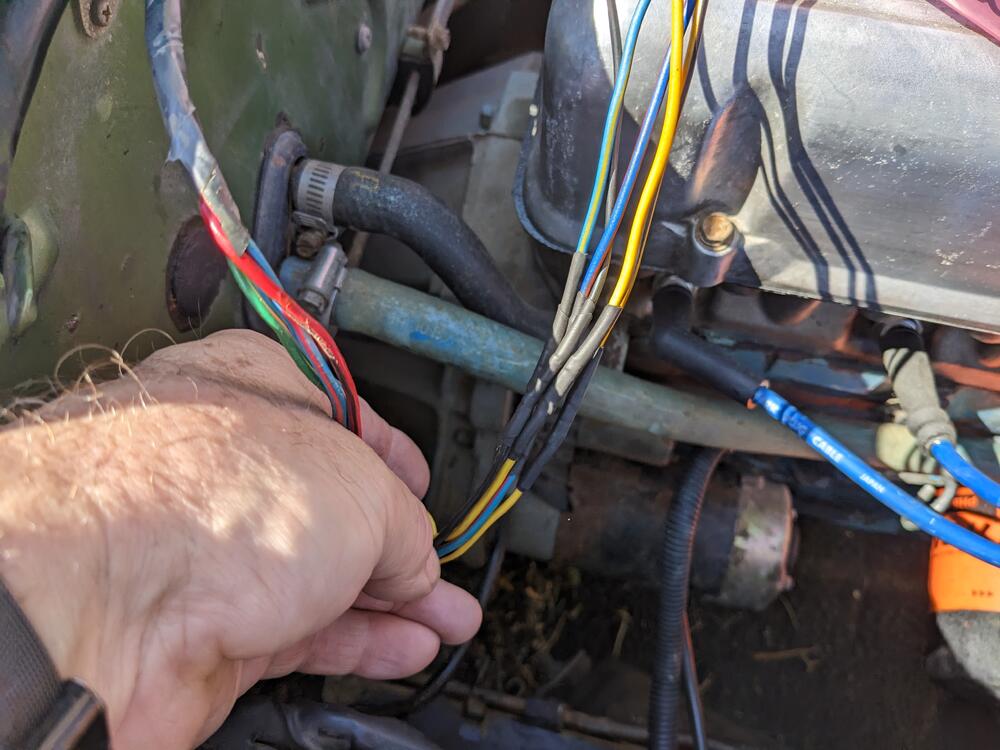

I attached the wires without the harness first, to just check the mapping from Datsun to Honda indicated in the earlier post

The wipers worked as they should - interval, low and high, parks as it should, so I put the wires into the connector

Moved harness routing over to the left & clipped it to the cowl lip

Put some butyl over the harness feed throughs, since I don't have the plastic sheath for the whole affair

arms & new 18" blades installed

checked the washer nozzle adjustment

Subscriber

Subscriber 1Points11,142Posts

1Points11,142Posts