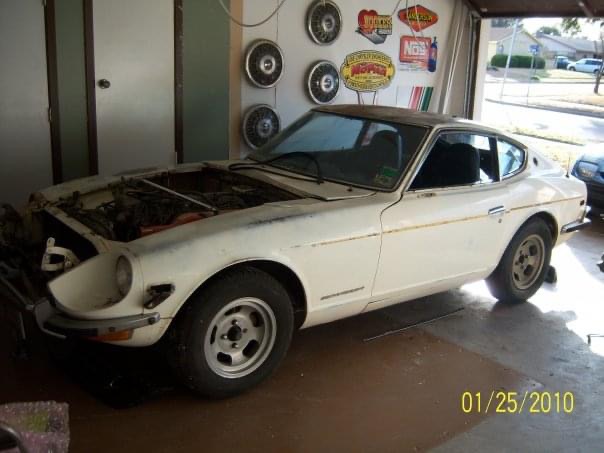

Thanks everyone. After taking in all suggestions, I just followed Robert Pirsig's advice: "Assembly of Japanese bicycle require great peace of mind." I eyeballed the stainless line and figured there's enough spare line length in the big curve to "stretch" it an enable the tight 90 degree turn, and I just futzed with it until it worked. Putting it on, taking it off, over and over until I mentally pictured how it should go. I used a sharpie to mark which axis to bend and when my tube bender wouldn't work, used imagination and problem solving to jerry-rig a tube bending jig until I got all the bends right. Like, I used the end of a crescent wrench, which was held fast on a 2x4, as something to carefully bend the line around. Sure, it would have been a snap to pay the exorbitant price for the 1972 cylinder, but I made $200 an hour adapting the line to the cheaper brake cylinder. Success!