The car is back on the road, and feeling really good. Almost a year after purchasing I have buttoned it all back up. There were no real "modifications" to speak of except the springs/struts, mostly reconditioning everything to good working order.

Thanks everyone for all the help and suggestions thus far. I'm sure we are just beginning

Here are the things I did in the last year:

Brakes:

- New MC

- New front calipers/pads/bridges/hoses

- New rear cylinders/hardware/bridges/hoses

Fuel:

- Reconditioned gas tank inside and out. Por15/Red Kote

- New flexible fuel lines everywhere

- New vent hoses, to OEM spec

- New fuel pump (mech)

- Fuel filter/G2 inline fuel filter at the back (overkill with reconditioned tank I imagine)

- Reconditioned Fuel gauge sender

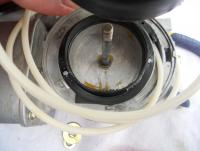

Ignition:

- Original points still in place for now

- Fully rebuilt carbs. Stripped down to individual parts/plated/rebuilt with ZTherapy bits.

- New OEM air filter

Cooling:

- Original fan/clutch/radiator. Works well with no leaks

- New hoses all around, new water pump, new T-stat and housings, original Temp sender

Drivetrain:

- New fluids for everything/ oil filter.

- New clutch master/slave/hose

- Original U-joints and half shafts. (seem decent enough for now)

Suspension/Steering:

- New Stagg struts all around

- Vogtland springs

- new balljoints/tie rod ends/bump stops/strut bearings

- New front control arm bushings (have TC bushings I may put in shortly)

- Original bushings still at: Steering rack, rear control arm, and TC.

- 14" Slotted wheels and tires from a friend.

- Aligned (they couldn't balance the tires because of age sadly)

Appearance/Cleanup:

- Removed original AC unit and hoses/ passenger foot well unit.

- Cleaned up undercoating all over engine bay.

- Clean up carb bodies/valve cover/head as best I could.

Future plans include:

- Drive Drive Drive

- Double checking fuel levels in carbs and making sure its tuned well at high rpm.

- Few interior bits that are aged. (Shifter boots and such)

- Front air dam

- new exhaust with a better note.

- New battery if necessary.

- Work on tightening up front end clunking