All Activity

- Past hour

-

Odd Bolts in Balance Tube

Perfectly? That seems unlikely. It's odd enough that a British thread pitch would be used on a Japanense car in the late 60's/early 70's. Why would British be used on the block and US on the balance tube? Chaos! Your thread chaser might cut some new threads though. People have used NPT in the oil pressure sender hole and made it work. Soft metal will distort.

- Today

-

Odd Bolts in Balance Tube

I salvaged a fitting, barb to male taper thread. A 1/8" NPT 27 threads tap lines up perfectly with the fitting I just pulled. That's what I'm going to chase the threads with, using lots of teflon tape, and install 1/8 pipe plugs. I have lots of brass hex stock available, I'll probably just make my own plugs.

-

Z's on BAT and other places collection

That one is tempting....my favorite color.

-

Z's on BAT and other places collection

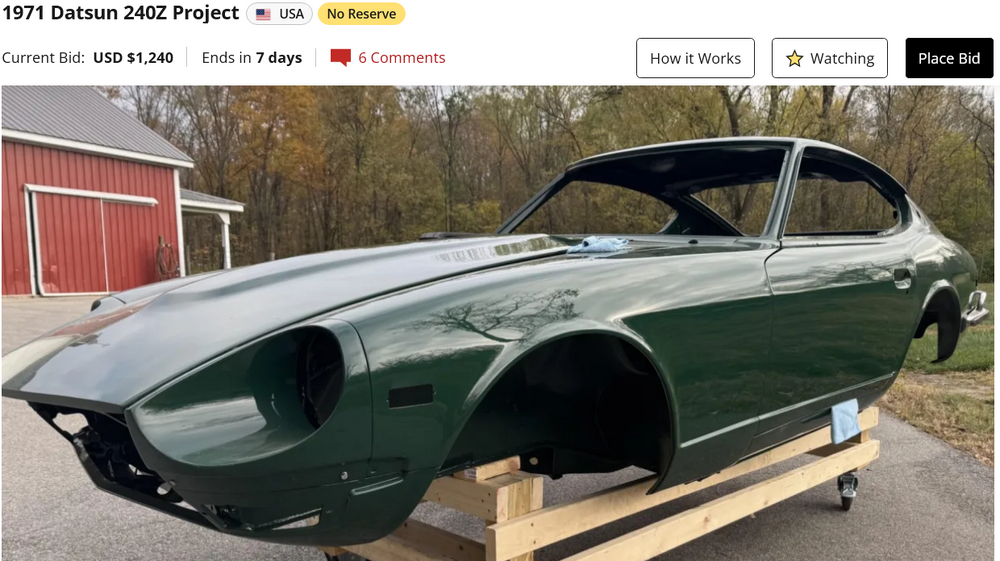

Here's a puzzle for somebody. Comes with a car cover. No reserve. https://bringatrailer.com/listing/1971-datsun-240z-330/

- Yesterday

-

Odd Bolts in Balance Tube

I used BSPT fittings on the N33 balance tube I have in my 260Z when I was doing the fuel injection conversion.

-

SteveJ started following Odd Bolts in Balance Tube

-

1975 280z Build

Read the articles here about the GM HEI module, if you find that your wiring is smoked or the factory Transistorized Ignition Unit (TIU), aka ignition module, is gone. You can run wires in the engine bay directly from that terminal block with the green and red wires. https://www.classiczcars.com/articles/electrical/

-

Odd Bolts in Balance Tube

Is BSPT a possibility? The prevailing internet Z forums' "wisdom" is that the oil pressure sending unit holes are BSPT. JIS VS BSP: What's the different ?Before choosing a suitable thread standard, it is necessary to understand from various aspects. This article will introduce the difference between JIS and BSP, so that you can better choose the thread

-

Khanyile1 started following 77 or 78 280 seat rail

-

77 or 78 280 seat rail

Hello - I got them available- let me know if you are still interested

-

Khanyile1 joined the community

-

Dome lamp repair

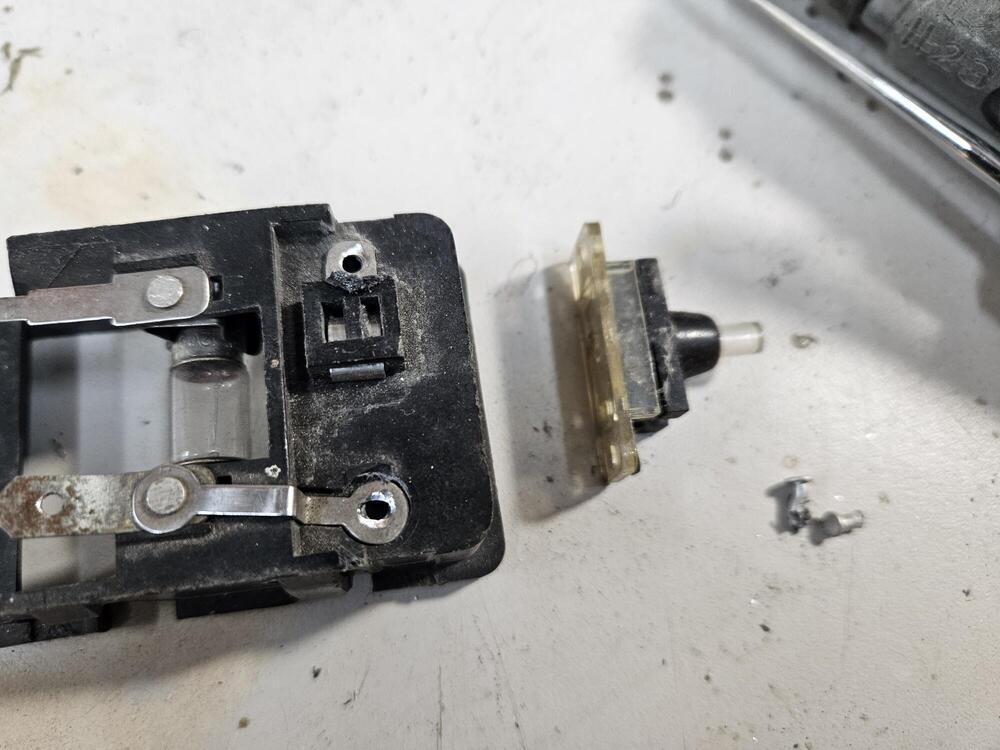

I used aluminum aircraft rivets - and like your pop rivets, I should have used a semi-tight washer on the squishy end. The sheet metal on the contacts is really thin. I also "re-squished" the (original) rivets on the bulb holders.

-

Odd Bolts in Balance Tube

You'll probably find they are JIS tapered pipe threads. Nissan used them on the 240Z in a number of locations in differing sizes, including for grease fittings.

-

emptech started following Odd Bolts in Balance Tube

-

Odd Bolts in Balance Tube

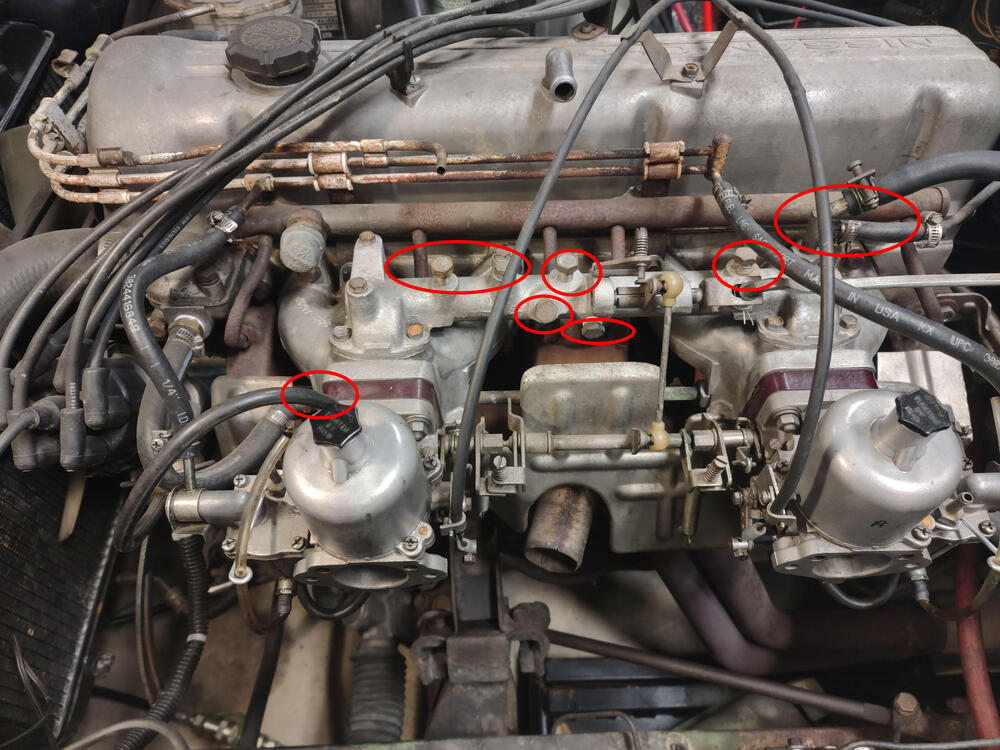

Just to let you know, what appear to be bolts plugging the holes in the balance tube are actually tapered pipe plugs. They have a different pitch than most metric bolts and if you force a metric bolt into the hole, you will ruin the threads. I know, I'm working on a 240z that somebody plugged the holes with ordinary bolts, now I have to correct their damage.

-

Float level advice, please.

Some of the holes had real taper plugs, pipe threads. Two of the taper holes were about 10mm and somebody had forced straight thread bolts into the taper holes, ruined the threads. I might be able to chase them and put in 1/8" taper pipe plugs. I don't know that the bolts made a good seal. I"ve verified that some of the threaded holes are 1/8" NPT 27, I'll chase the threads and with teflon tape will repair the holes. I have a 1/8" to barb adapter I can connect my vacuum gage, haven't used it in years. Jim

-

The time has come for Zedyone to really look at brakes.

Sounds like you're saying things have been just fine then something changed. As opposed to the brakes having always bothered you. If it was mine I'd find the source of the sudden problem before "upgrading" anything. Otherwise you could add the upgrades and end up with the same problem, never solved.

-

Float level advice, please.

I included a photo. I circled all of the ports in the vacuum manifold, I think they call it something else. I bought the 240z assembly used on ebay, so somebody had messed with everything, I mean everything. They plugged many of the threaded ports where things, mostly emission items attached. They did not use Teflon tape, and I don't even know if the threads matched. I'm thinking about removing all the plugs, which in some cases are just bolts. If the threads are not right, correct them and use teflon tape to seal the threads. It would be easy to seal off the vacuum lines going to the master vac and transmission.

-

Float level advice, please.

I agree with Patcon. I'd cap off everything you don't really need right now, including the brake booster and the transmission. And yes, I think a vacuum gauge could be helpful. You should be in the 17-20 inches of vacuum at idle. If you're at 10, there's a leak somewhere. I also think pics could be helpful.

-

The time has come for Zedyone to really look at brakes.

Oh, and I'd be hard pressed to believe it's a malfunctioning check valve. If you're off the gas pedal when you're on the brakes (as you most likely are), the check valve won't really matter because the manifold vacuum is high (because you're off the gas pedal). Does the idle go up a little bit when you press the brakes sitting at idle? That's a typical sign of a torn diaphragm.

-

The time has come for Zedyone to really look at brakes.

The reaction disk won't just fall out all by it's own. If this problem occurred all of a sudden, it's not the disk. A torn booster diaphragm will cause a hard pedal, and so will a malfunctioning poppet valve inside the booster. Either way, you're opening or replacing the booster.

-

1971 HLS30-14938 "Lily" build

Hahahaha!! It's true!!

-

Dome lamp repair

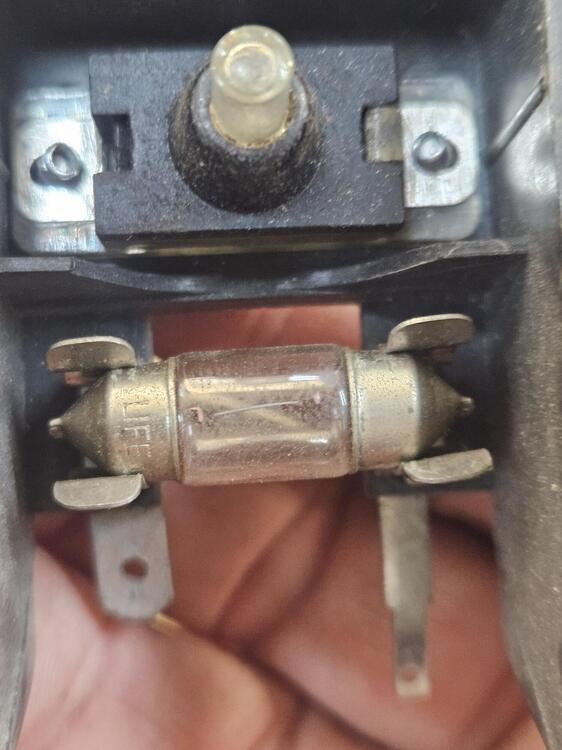

I made some progress last weekend but not quite there yet. So I drilled out the two rivets at the switch. Replaced them with aluminum pop rivets for now. That made it better but it still didn't work. There was also a continuity issue at these other rivets The only problem is I used a grinder and as the rivet heats up it melts the housing. A die grinder might be a better choice. The LED lamp I was using worked for a moment then freaked out and wouldn't go full brightness. I ordered some more. So we'll see. I would like to replace the aluminum rivets with small copper rivets if I could find some good candidates and a proper way to staked them. They need to be about 0.095" or about 2-2.5mm OD

-

1971 HLS30-14938 "Lily" build

So Cody and I got the tachometer working tonight. Big thanks to @cgsheen1 Chuck. His explanation for current flow to the tach and back made it all make sense. I took the tip of my thumb off with a hammer tonight in the shop, so I didn't get the last piece of leather in. Opposable thumbs are really useful, as it turns out.

-

Floor pans, help me choose

I have used the Zcardepot style pans in the past. It is a lot of work getting them to mate up well to the tunnel. If it were me, I would get the KF pans. I think they are better pans and will give a better finished product. You may not care today about an OEM look today but you might in ten years...

-

Float level advice, please.

I think I would cap everything on the manifold that uses vacuum with an assortment of rubber caps. Then if you can get the engine started and sorted, add them back one at a time to check for vacuum leaks

- Last week

-

Float level advice, please.

I pulled the hose going to the master vac, sucking on it or blowing into it no obvious leak there. I did not try compressed air. This is a 260z with an automatic transmission. I see vacuum lines going to the master vac and down to the automatic transmission. There is another vac line from the front carb to the vac advance on the distributor. There are two fuel rails, one from the fuel filter/fuel pump that feeds the two carbs, another one that feeds excess fuel back to the gas tank. The top hard line has nothing connected on either end, I think it was part of the smog system. I did find a hard line going somewhere, think it was a vent line to the gas tank, probably went on the charcoal filter cannister. The only thing that makes sense to me to have to turn the nuts so far down is a vac leak, but where? Would there be any point in connecting a vac gage to the intake manifold? I'm puzzled. I haven't tried using a propane blow torch to leak propane around suspected leaks but it's not like this car has vacuum lines going all over the place, it doesn't. I'd attach photos but don't know what would help at this moment.

-

Float level advice, please.

CO: I feel pretty confident that the float levels are now correct. I have not checked for vacuum leaks, if the rubber diaphragm in the master vac was ruptured, that could be giving me a lean mixture and turning the nuts six turns down would compensate. Somehow I need to cut off the vacuum line to the mastervac. The engine used to have a carbon canister which I removed. I wonder if it had a vacuum line going to it, if so I wonder what I did about it. I agree, years ago when the car was driven, had to pull the choke back to get it to start, then would back it off a bit to raise the idle speed until it warmed up, not the case right now.

-

The time has come for Zedyone to really look at brakes.

I have front Willwoods on my silver Z with 15 inch Panasports. Probably right about reaction disc….won’t just fall off if you haven’t removed booster. I guess hard pedal could be a bad Brake Booster or check valve.