All Activity

- Past hour

-

The time has come for Zedyone to really look at brakes.

Ok, cancel the Yarbinator. I found a video on YouTube and it only takes three wires. Frankly, the video is one of the best produced car vids I’ve ever seen on YT. If I knew how to link it…

- Today

-

Rear Drum Cover Removal?

Mine has 2 of those holes - does it matter which I use?

-

Nothing to do with a Z

It's been a whole year since the surgery! Can hardly believe it, time flies when you're on the better end of healing. Thanks for all the prayers and well wishes, they worked. Next is a mid-foot fusion that I'm dreading but the docs said after a year with the knee replacement they could do it. I had planned a day of relaxing in the driver's seat of the 240 but it has rained like a cow pissing on a flat rock. Maybe tomorrow?

-

Rear Drum Cover Removal?

Had to resort to the old drum puller once. Came off with a very loud bang. Putting on a couple of lug nuts loosely prevents it from exploding into your lap

-

Rear Drum Cover Removal?

Was that an accident or wanting them off? BFH love!

-

Odd Bolts in Balance Tube

Oh, and I don't see anything else glaringly wrong in the pic, but was wondering... When the flat top to round top conversion was done, did they (you?) use a new intake/exhaust manifold gasket, or reuse the old one?

-

Odd Bolts in Balance Tube

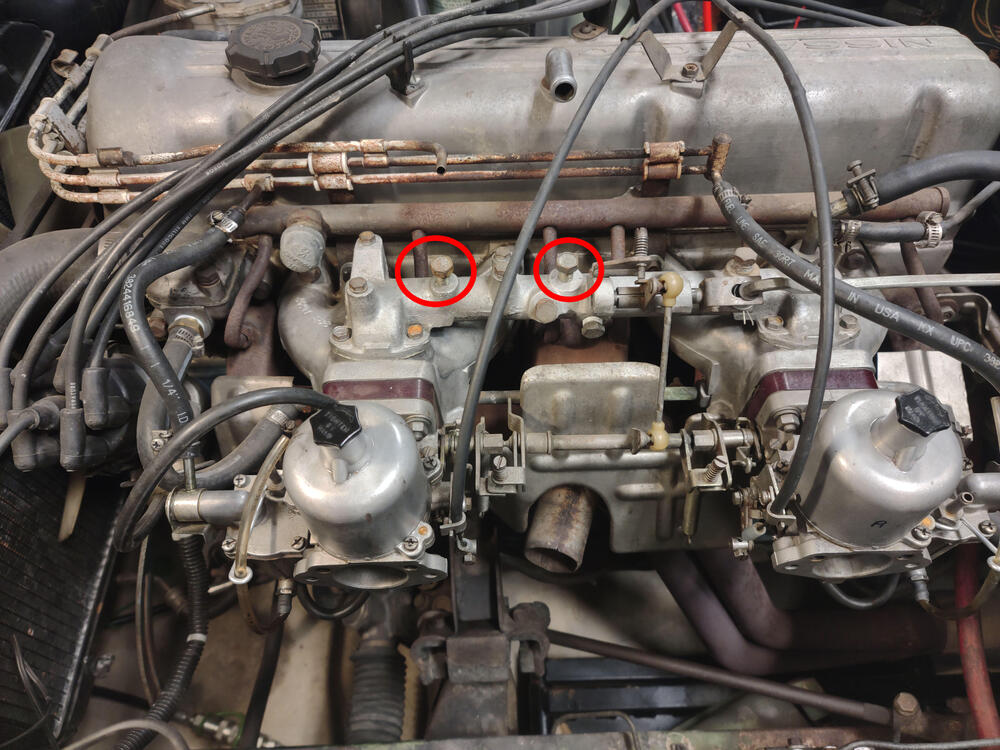

Well let's hope fixing those two plugs helps your running issue. If the two 10mm head bolts were screwed in somewhat tight, they probably sealed "mostly". If those bolts are the only vacuum leak you found, they probably weren't large leaks.

-

Saving- 04858

I didn’t make the larger pieces of upper frame rail. Same car I bought my roof from I also bought all his straight scrap pieces . It was enough of a challenge to make that 1” filler strip between the pieces he sent me - ha . I don’t have the tools to do that complex of bends and curves. The tool is just a right angle air grinder with a Roloc sanding discs . I use that tool more than most . I have cut- off wheel mandrel and scotch bright disc options . I actually have 3 of them with different mandrels on each .

-

1975 280z Build

There was a post around that had someone replacing the guts of the old module with the new HEI but I cant find it. I might do that, but mount the box on the firewall or something. I like that it would appear more period correct. @EuroDat did that to his '77

-

Rear Drum Cover Removal?

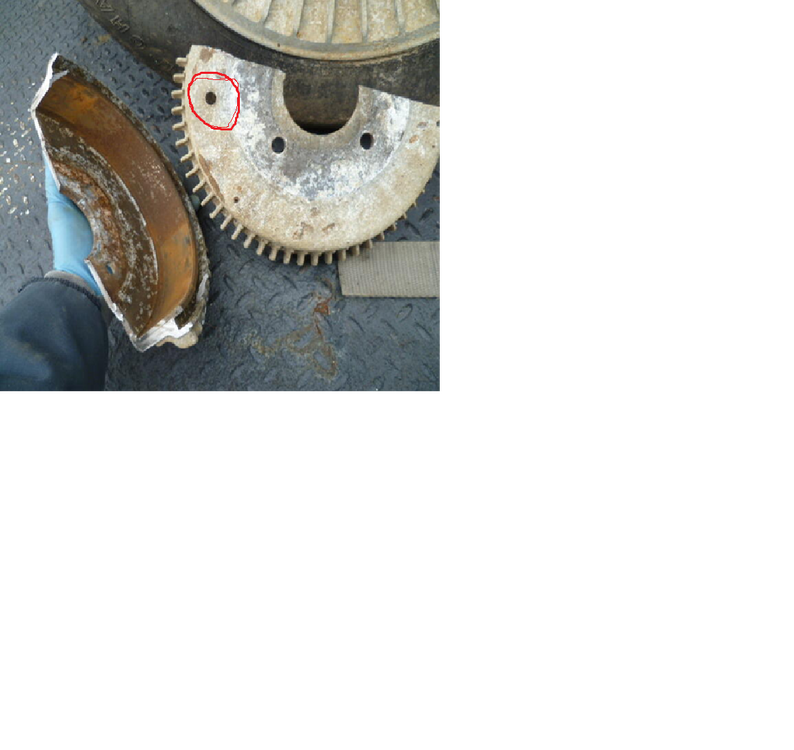

That should be it in the red circle. I saw my OE aluminums the other day cleaning up my storage building and they still have the rubber plugs in them.

-

Rear Drum Cover Removal?

Wait i thought the cog was accessed through the hole on the front of the drum?

-

Rear Drum Cover Removal?

I really thought the access was through the backing plate that the brake pads are attached to. Seems like there's a rubber oblong plug that you pull for access to the cog wheel to back the pads off.

-

w3wilkes started following Rear Drum Cover Removal?

-

Odd Bolts in Balance Tube

As I'm working on a 260z engine, I found somebody decided to plug some holes in the balance tube by using two 10mm straight thread cap screws (bolts). The original holes were tapered but they forced metric cap screws into the holes, ruining the threads. Notice they were only able to get the screws in part way. I've attach a photo, I circled the two locations. Without drilling the holes out I was able to thread the holes with a 1/8-27 tapered pipe tap, thus allowing me to use 1/8" plugs. All other plugs I've found seem to be the proper threads. Jim

-

Odd Bolts in Balance Tube

Yes, I understand how they are designed, I just wanna use them how I wanna use them! LOL I really wouldn't like the look even if the heads DID bottom out, still kinda klunky looking. The BSPP plugs on the other hand (they have a lower profile head), look pretty good, but they won't bottom out in the tapered holes.....so I guess I could tap the holes to a parallel thread and use thread sealant. I think you are right though, once I get all the holes I need to plug measured, I will order the allen screw type.

-

The time has come for Zedyone to really look at brakes.

Lol!! The Yarbinator. Love it! ☺️

-

Odd Bolts in Balance Tube

Tapered pipe threads are supposed to tighten up on the threads, not the underside of the head. In fact, if the head were to bottom out, the threads would run the risk of not being tight enough to seal. In other words... The hex headed plugs you have there are working exactly like they should. You would stand a better chance of achieving your "clean look" with the recessed hex head "Allen screw" type plugs.

-

Rear Drum Cover Removal?

- 1975 280z Build

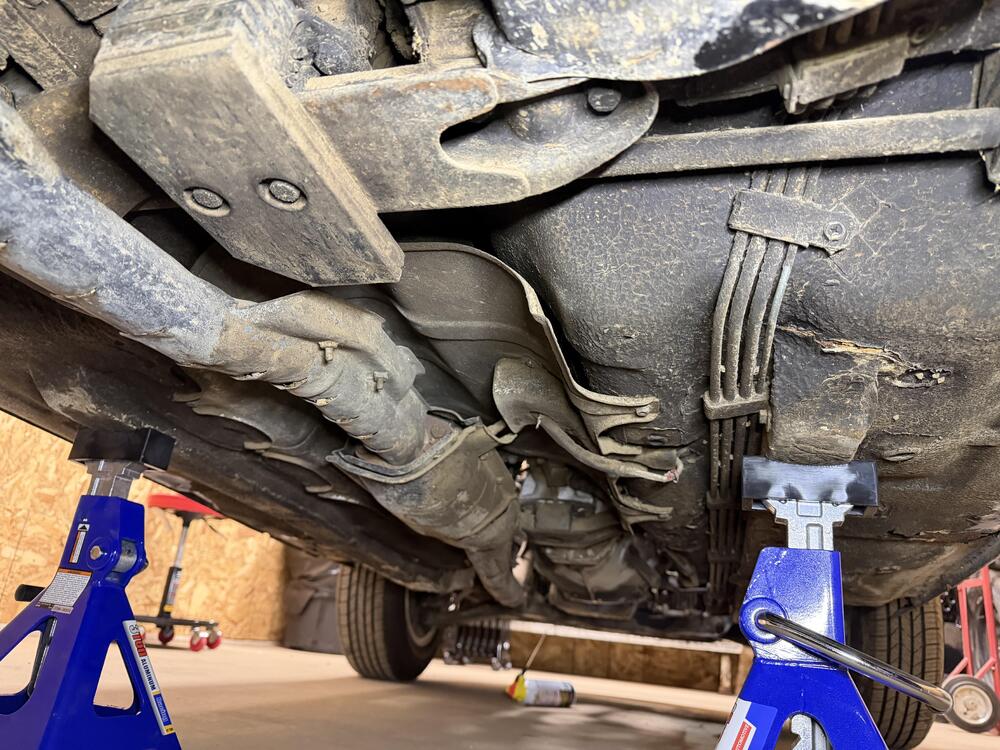

Little more poking around today. I ended up just ordering a HEI module specific heat sink off amazon. I had considered just finding some sheet metal or aluminum, but I didnt have anything laying around and a small chunk from the hardware store was almost as much as the heatsink itself. I think its going to end up on the other side of the strut tower. There is a nice empty space there I can utilize. I don't really want it there, but for the sake of simplicity, thats where I am going to put it. There was a post around that had someone replacing the guts of the old module with the new HEI but I cant find it. I might do that, but mount the box on the firewall or something. I like that it would appear more period correct. I started looking more closely at the fuel system, pretty much all the rubber is dry rotted and unusable. Same with the vacuum lines, so I ended up ordering a bunch of hose and Ill just replace all of it. Im not sure about the hard lines yet. I jacked up and crawled under the car and drained the fuel tank. It was pretty much empty but the stuff that was in there was.......nasty. The fuel was incredibly dark and full of debris. I know there is a place in town where I can get the tank reconditioned, so I'll look into that. While I was under there, I took some pics of the undercarriage. I dont think its too bad. It was a New Mexico car after all.- Odd Bolts in Balance Tube

OK, here we go..... The threads on the balance tube all seem to be BSPT (1/8" and 1/4") The threads on my intake manifold where the water lines used to go are still a mystery. I have a feeling they are just a metric thread (not pipe thread), so I will have to do more investigating when I have an assortment of metric bolts to try. Also, my thermostat housing is at my storage, so I cannot check those outlets right now, either. I guess everything is a process......stay tuned! Here's my new dilemma; The pipe plugs I ordered from McMaster for sizing purposes are external hex head, and they do not thread deep enough into the balance tube for the head to bottom out and seat on the flat of the balance tube. Not the clean look I was going for. I think I'll try the internal hex drive (like a regular socket set screw) plugs and hope they sit flush or a little recessed when seated. If I don't get a good, clean look that I like, I may have to weld the holes up and grind them smooth. Oh, the lengths we'll go to for these cars!!!! LOL- Rear Drum Cover Removal?

Sounds good - I'll give it a shot. Thanks- Rear Drum Cover Removal?

If the light is right you can probably see the notches through the hole. In practice you just jam a small screwdriver in the hole until you feel it grabbing the notches of the adjusting wheel, Keep jabbing to get the wheel to move. It's kind of tedious, you don't get much movement per unit of effort.- Rear Drum Cover Removal?

Mine actually has 2 holes on it which is weird since all of the drums I've seen online only have 1. So I just spin the drum until the hole is near the wheel cylinder then use a small screwdriver to turn the shoes in?- Rear Drum Cover Removal?

- Rear Drum Cover Removal?

Gotcha, I'll halt the screw hunt. How do I gain access to the area with the adjusting wheel on the back?- Rear Drum Cover Removal?

Z's don't. No guarantee that the drums will come off even if you back the adjusting wheel off. People have had to sacrifice the drums if they're really stuck. But, the best place to start is the instructions in the FSM. Back off the wheel, see what happens. - 1975 280z Build

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.