Everything posted by dutchzcarguy

-

123 Ignition plasma ball

Use a standard .. what is it.. 20-25 Kv coil.. all that 123 ignition nonsense with 40+ Kv… gives you only one thing… trouble!!!… just my 2 cents...

-

Parts for Sale: 240Z quarter panel right NEW NOS

Sorry but what is a GT junior? Italian? Those brown spots (round wheel arch and where the bumper go's are not rust? pics after a good cleaning??

-

Modern power antenna on original up down antenna switch

Problem is those antenna's are not worth looking at.. leave alone the hassle to install them.. they work a few weeks or month and break down.. those relais probably cost more than the antenna, buy a good antenna or don't do it at all.. just my 2 cents..

-

280zx 1979 2+2 slick roof restauration

Yes Bart, it is going well, i try to work on it every working day and i get a lot of support of the guys who work at the bodyshop. Also from the owner of the shop. Because i count all the hours i work at it (or someone else, like the pro painter or bodywork guy) last week we went past the 500 hours ! working on the car and i think it's going to be another 250 to complete the restauration.. ? At least... These days i'm working on the fenders, left in particular and the hood (or bonnet!) whole lot of.. you guest it... sanding! ? Even a brand new bonnet needs work, a Original NISSAN hood… where do i find them haha...! Restoring the left fender.. left lower part of left front fender.. I had a problem with heat, despite the copper/silicium welding i now did.. but about 20 little blows with a special hammer made it strait.. learned again something! Then i discovered that i welded it to straight down, had to correct that.. now the lower front part deviates inward as it should! (see last pic in this part.) lower front left fender. Putting in a little piece in the wheelarch. If you want to do this… i told the owner of the shop you have to have a diploma to weld newspaper paper.. ? Sanding left and right fender.. (still busy..) Sanding (with some rattlecan paint to sort out the imperfections). Making the fenders and hood ready for epoxy coating. (later on the blue paint is sanded off completely before epoxy.) Front left corner, welded in part fender, deviates inward.

-

Inner fender liners

Nissan called them mud-guards if i remember correctly...

-

Newbie

You mean a rotisary? i think? ? Like to see some pic's of the bad spots on a USA type 280zx.. mine, (you can find it under: restoration of a 1979 2+2 slickroof 280zx) was almost without any rust, only the carglass guys had made a mess of the frontwindow edge at some time.. nice to see someone is going to restore another 280zx.

-

repairing a circuit board

Thats why i gave the advice to put the wire on the component side.. as pro's do.. (i've worked with studer revox machines, and ones opened up a TEAC... wow, there are a lot of those wires in there! A ReVox is well engineered.. they don't do/need that!)

-

repairing a circuit board

Clean the board well, then take of the damaged line(s) on the board and drill 2 small holes (1mm) at the ends of the line that has to be replaced and then put in a .8mm wire on the other side (componentside) of the board. It will look good and work well ? (Make shure the board is clean for soldering, use good resin core solder tin. )

-

Need to sell a 240z

Sad story, i would put in a lot of pictures, they say more than a Thousand words..

-

78 280z Thoughts

I'm with Charles, only if the rest of the loom is a firehazard i'll put in a new loom at this time..

- 280zx 1979 2+2 slick roof restauration

-

280zx 1979 2+2 slick roof restauration

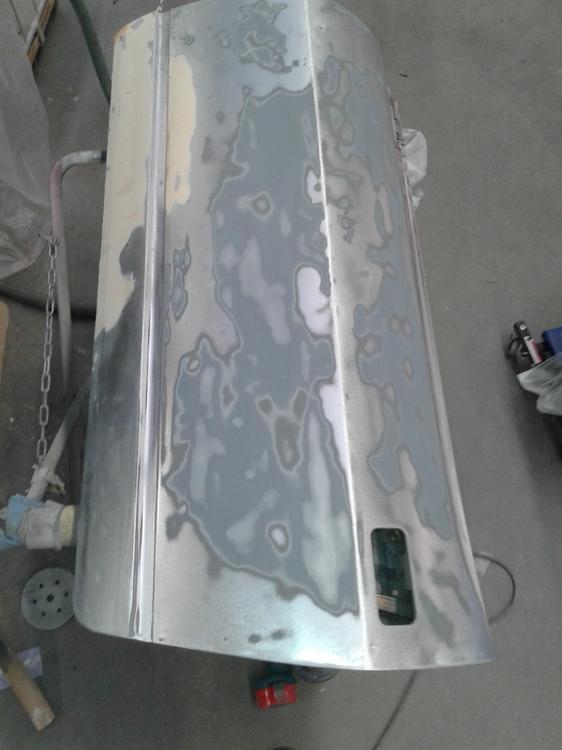

Another week at the painter/bodyshop.. Most time sanding and eh.. sanding and then…. some sanding! ? Also used some new to me tools.. to get out some dents that were to severe to lieve alone.. Did i say earlyer that sanding is my favorite hobby? NOT !!! First here the pic of the welded in new part were the left mirror sits. I know now the pro's and cons of copper/selicium welding… one con is the weld tore easely when you want to lower it by hitting it with a hammer! So a second weld was neccessary. Today (saterday) was a important day.. The first parts became a layer of epoxy in the spraybooth…. BY ME! I've used a spraygun many years ago but not much experience with them.. i think this went well.. Some small dents are still in there but... not bad for 40+ year old doors! After this they get smoothed out with some bondo and become a new set off paint. (Car will be painted in Nissan TK3, an Original nissan zx color.) Some other pic's of prep.. and sanding.. bare metall pic's.. Rightdoor mirror, bare metall. A "college"had some left over bondo.. i let him leave it on a little dent.. Next i'll probably do the hood and frontfenders prep and epoxy...

-

FS5W71B Rebuild Thread - Tips tricks and discoveries!

Obviously…. ( but there are a lot lathes with reverse gear..) Nice tools!

-

Steering wheel shake, my story

-

Steering wheel shake, my story

Last summer i had some 280zx turbo wheels under my 240z and discovered that the wheelnuts i use for the winterwheels (are aftermarket rims) are a different size diameter as they are not conical. That gave me a lot of shimmy issues! check the diameter of the wheellugs and the diameter the rims need.

-

280zx 1979 2+2 slick roof restauration

Another week at the bodyshop has gone by.. some progress has been made.. Made the lower parts of the left fender this time, to weld in. Lv = (links voor) or.. left front. front part of the fender. The rear lower part of the left front fender is made but no pic's yet.. Then there was the left door, did some as we say "beeldhouw werk" sculpturing haha, it needs after 40 years and a not perfect strait weld some bondo.. Almost ready for paint... there was a spot that was not perfect.. where the mirror sits or sat.. some rust spots, i better weld some copper in.. ( sp.L= spiegel links) mirror left. maesurements are centimeters. cM. Welded the holes from the mirror.. but then, when i checkt it, the metal was to thin... At the end of the day i went for the better option... I welded it all around.. but no pic yet.. These are the small things that take a lot of time but they are necessary!

-

Clearly.... a Fastback Z

Those rear tires are NOT big enough!.... Yeah overalll….BARF...

-

240Z Hazard switch differences

The first few times i used my early '71 240z I flattened the switch several times with my knees! Then the brake lights stayed out..(US type switch with the 9 contacts!) the switch was broken inside.. Now i'm still driving the car almost 20 years with a frozen switch in off position, some glue keeps it together hahaha… and it's handle is flat with the dash.. i have to put my right knee somewhere haha ?

-

seat brackets

My 02-'71 doesn't have those ribs either.. Some extra floorstiffness would be also good for bigger europeans ? When i put in a whole new floor i didn't know of them so mine still has none.. oh well, it's 1mm steel i used so it is already a bit stronger than the old floor..

-

FS5W71B Rebuild Thread - Tips tricks and discoveries!

Probably? it's seems to be the better Nylon... Couldn't you make just a new set on them, just a little bit bigger and secure them with rivets (like it was already) ?

- 280zx 1979 2+2 slick roof restauration

-

280zx 1979 2+2 slick roof restauration

It's very nice to get the chance to work on your own car in a professional bodyshop/paintshop, i can use all the tools needed or bring my own if i want to! So i askt if i could bring my own MIG welder, not necessary we have a lot of Mig's.. ? so i could use the copper/silicium MIG welder! It works with a lot less heat so the workpeace does not bend from overheating.. (Also my own NISSAN Toolcart on this pic!) I didn't Grind away the whole weld, it's not necessary and stronger this way. You can see clearly the copper in the weld. Outside front fender in zinc paint. Just looking if it fits..2nd part on low right already welded on/in.. Used an english wheel at home for a smal curvature. Question of the day ? does the 280zx frontfender only have 1 screw or bolt to keep it in place here? and is it a screw or bolt? (if you tell me i don't need to go through a thousend pic's )

-

FS5W71B Rebuild Thread - Tips tricks and discoveries!

that what i thought to, leaning and holding on to the shifter in 2nd... wears out the fork..

-

FS5W71B Rebuild Thread - Tips tricks and discoveries!

Hihi so funny… i go shoft my shifter….

-

FS5W71B Rebuild Thread - Tips tricks and discoveries!

If you made the tiltle you have some weeks to change it.. or month's, don't know.. maybe @Mike can tell..? On topic, why not weld the old fork? Steel or aluminum (aluminium also ? ) i weld both… This week i learnt how to weld with copper/silicium with a MIG... yeah! still learning new tricks!! (it is a colder weld! within days i will show some welds in my thread: restoring a 280zx slick roof.)

.thumb.jpg.62cafa2d1caefac72f85636549d45fd7.jpg)