Everything posted by Patcon

-

Palco/Dashtop interior panels

I think I'm gonna have to do the same thing. Some of my panels are bad and I don't want to have half look new and half look old. I know https://resurrectedclassics.com/ show them also. A whole series one set is close to $1000

-

Designing A/C System Using Other Cars Parts?

That sounds like the way the idle up was handled on some older cars in the day. When the compressor was energized it triggered a relay that actuated a solenoid that push on the throttle linkage enough to idle it up a couple 100 RPM's

-

Black out areas

I was looking at some of my spare quarter windows. I'm still not sure this wasn't painted black It scratches off, like a coating

-

No vacuum on front carb

https://dannysengineportal.com/wet-compression-test-how-to-do-it-what-will-it-tell-you/

-

Replacement tar mat

@CanTechZ Mike, Do you have any recommendations on cutting tar mat? I believe the material I ordered is in sections. So I will have multiple panels to each pattern. C

-

1970 240Z Floor Tar Mat Templates

I had an issue, I opened the front floor DWG in Autocad LT no problem but I couldn't open the other two DWG's. "Drawing was created in an Incompatible version"?? I can't figure out how to plot portions of the PDF's because of my 24" plotter size I Figured it out, I can use the poster setting with a 1" overlap and that will print it for me out of Acrobat Thanks again for the effort to publish these! C

- 9 comments

- 1 review

-

Video recommendation: "My Mechanics" restores a 240Z

Nicely done!

-

No vacuum on front carb

They do seem low but consistent. I would expect 150-175. Maybe 135 at a minimum Did you crank the engine until the pressures quit rising? Yes the throttle should be wide open... All 6 plugs should be out too! If the numbers are still low, you can add a little oil to each cylinder. If the numbers rise on the "wet" test then the rings are worn or damaged

-

Rear Diff.

I guess the reasons I would favor the R200: Nissan evidently found it to be a good idea to go to the larger ring gear. (wear?, strength?) Obviously it should be stouter, but I don't really thrash my cars like that anymore. My #1 reason would be there seem to be a lot more ratios available in the R200. Especially if you go to an R200 out of a more modern car in a hybrid z type manner. Potentially R200 ring and pinions might be available also if you had a really precise ratio need...

-

Rear Diff.

What's driving the return to R180? Most people want to go the other way...

-

Black out areas

More info in an older thread

-

1971 HLS30-14938 "Lily" build

So I got the headliner trim in Gonna have to pick up the pace to be ready for Zcon 2024 Momma is starting to crack the whip

-

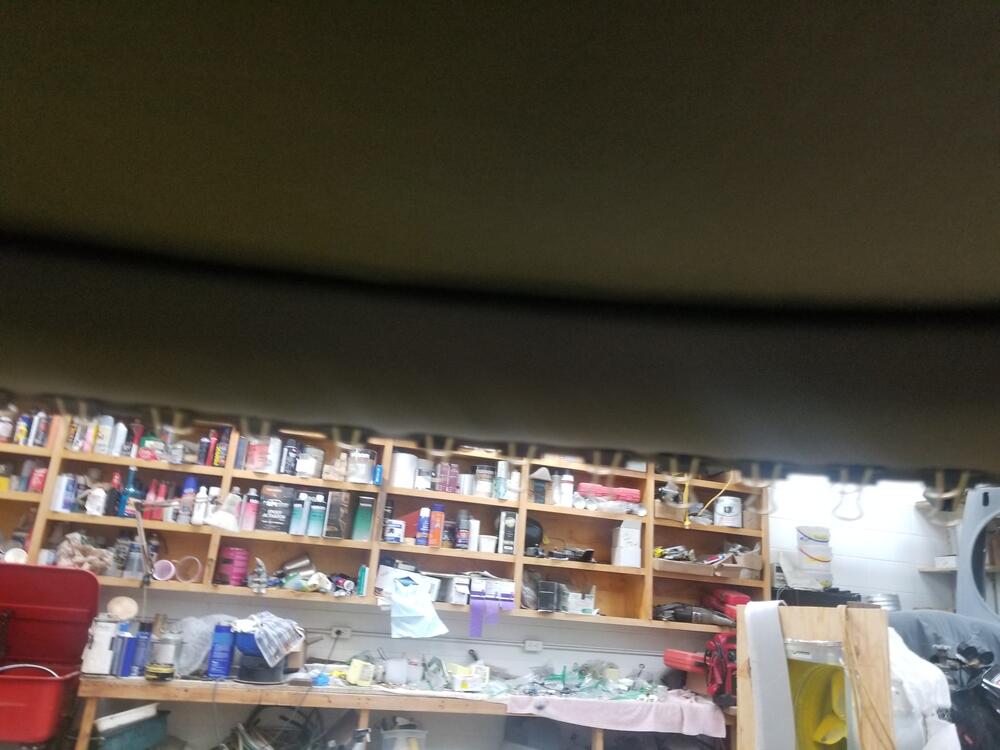

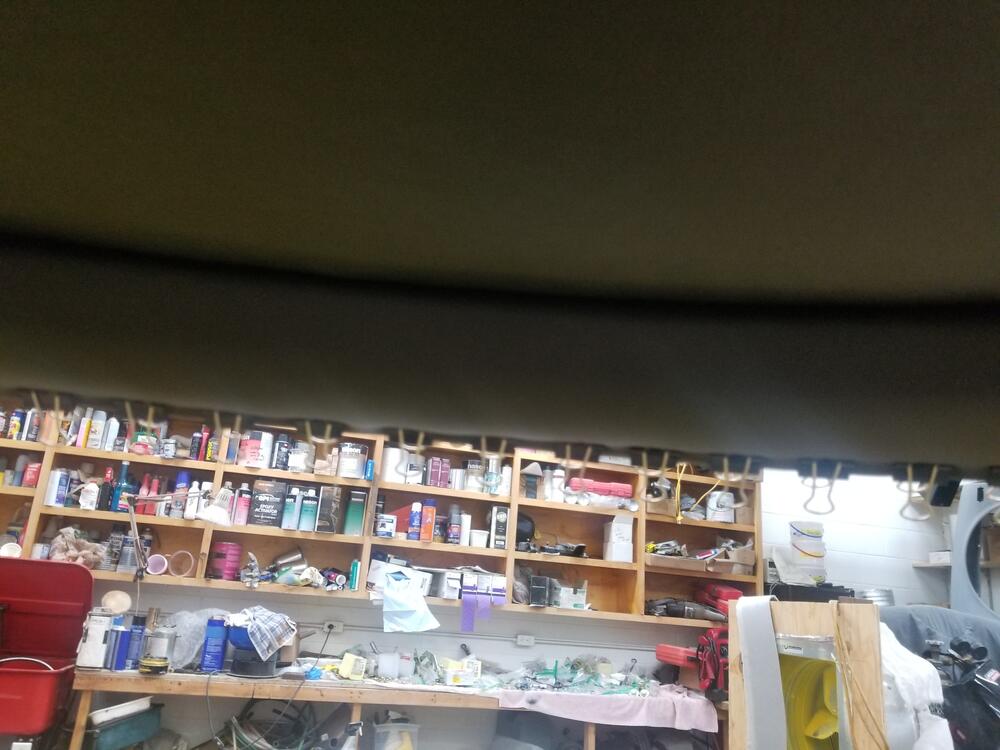

Interior roof and pillar trim

I tried to get some better pictures of the interior roof trim I will work on this fold a little more. I glued the passenger side and it looks a little better. I'm sure I can make this detail right with a little more fiddling

-

Clutch fork throw

So measured the Exedy pressure plate The Luk pressure plate was 44.3 mm The Exedy 06030 is 1.927" or 48.95 mm With the new collar and bearing it's 92.4 mm to the ears

-

Fuel rail upgrade?

I agree, it should be a set and forget item but it is nice to have for roadside diagnosis or just making sure the pump and FPR are good

-

Guidance: installing A/C into 280Z

Bear in mind R-12 has gotten very expensive lately and might change your monetary calculations. Check cost and availability before choosing a direction

-

original jute material

That would be great!! C

-

Z's on BAT and other places collection

I think the $66k is with the buyer's premium included

-

1970 240Z Floor Tar Mat Templates

I love that you posted both pdf and dwg. I have autocad and the dwg is so much easier to manipulate for printing Charles

- 9 comments

- 1 review

-

-

- 1

-

-

Z's on BAT and other places collection

Looks like $66k

-

Z's on BAT and other places collection

Steve, I saw that page but it didn't show bid numbers

-

Interior roof and pillar trim

So I started off the day tapping the holes for the visors, mirror and coat hook. They are all 5m x 0.8 I pulled the front windlace off and redid it a little bit. I tried to get it tucked to where the edge was pretty even across based on the RV mirror bump out. Then I clipped it off. Then I pulled off a few clips and ran the windlace from the middle out. My windlace had a small white dot on it near the middle. I don't know if that was a factory thing or not. I used a rubber mallet against the windlace and hit it with the brass hammer to seat it. Then I trimmed it back The kit I have is from MSA and the foam is grey open cell with some kind of backing on it I found the middle of the header piece and marked it. Then I used the spray adhesive from the kit. It works pretty good. I glued it up into place and then trimmed it and cut all the visor and mirror holes. Then I used weld wood contact cement and glued the header piece in. I didn't pull it very tight and after the clips are on it looks good. The sides are actually the harder portion. I had to slide the pieces from the kit backward and forward on the ceiling to find the right place where the A pillar material would hit right. Then I installed the windlace. Then I glued the upper edge of the roof trim above the door. I drew a line where it meets the seam so I knew where to run cement. Pull it a little and clip it off Then I figured out the fold technique and locations. Y'alls pictures were really helpful with this Then I glued the inside edge of the A pillar and clipped it. Then I did the outside edge I'm not really sure where to stop the bottom of the A pillar? This took about 225 19mm clips... This where the window trim fits. So the roof trim gets covered from here back That is good to have that about behind me. There is a little detail work I need to do at the folded seams to try to fasten them down and make them look good. I might use a little super glue for that. Would have been much easier on the rotisserie!! "Tuition"...

-

Clutch fork throw

So I received the new collar yesterday I ordered a different one but it was out of stock. I selected another product and Rockauto shipped it for the same price as the cheaper one. Which I thought was cool! It looks to be about 10mm taller. I might go over to Cody's tomorrow and check out the total stack height

-

Z's on BAT and other places collection

Is there a way to view the auction sold prices on Mecum?

-

BC Z cars

Pictures don't appear to be public...

Subscriber

Subscriber