Everything posted by Patcon

-

Lost the Parking Lights (with diagnostics)

Good find. That wire got a little warm...

-

Caswell Plating

I don't know. The only time I have seen someone use alcohol was to dry the part at the end of the process

-

Cody's Goon

-

Caswell Plating

I also had some issues with this carb shaft. I was getting what I thought was heavy shadowing. So I reran it... Now it is entirely possible I didn't get it clean enough. So I bead blasted it again and degreased and hung it so as to expose these areas better to the plates. This is what I got. It came out really good. As an aside I had this piece not turn out. Evidently after bead blasting there was no circuit into the swivel part of the choke linkage. The bar plated but not the connection. I stripped it and when I restrung it I added a wire through the barrel and it came out fine...

-

Caswell Plating

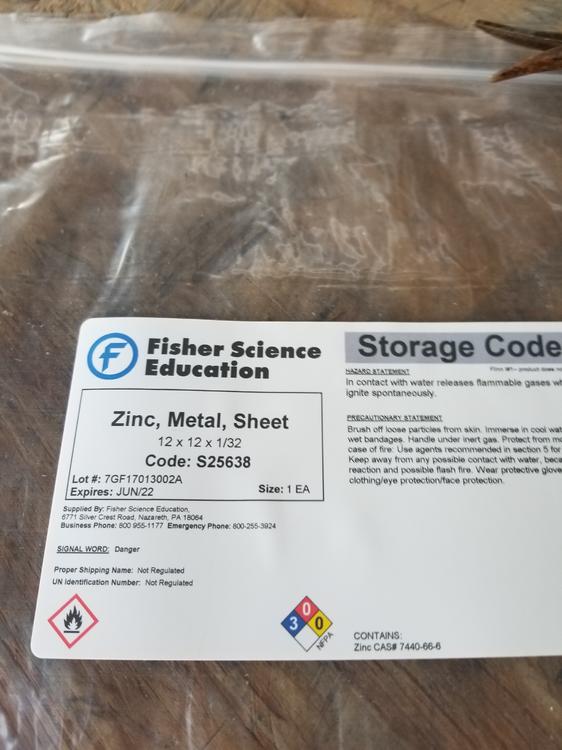

So I did a lot of plating. Mostly little carb pieces and such. Got pretty good results. I found a source for zinc. I bought a 12x12 plate from Fisher Science. I cut it in half and made 2 large anodes. I folded some tabs on the plate, but I beat them flat, which is a mistake. The zinc is so brittle the tabs will just crack off Then I started on the line insulator pieces. That didn't go so well... By the way is this line bracket 280z specific? so I backed up and was figuring I was having a connection issue at the part. The hanging wires were plating beautifully T Those are both raw zinc, no chromate So I took 4 pieces all the same and wired them all differently. 2 with heavy wire and 2 with lighter wire I degreased them and put them in the pickle until they quit bubbling.. Then I plated all 4 in the tank at the same time. I rechecked my areas and plated at 0.14 amps/inch The one on the far left had a heavy wire tied top and bottom and it did the best. Second best was the other heavy wire 3rd from the left. Then the two lighter wires. I am emailing with Caswell and got this advise: After plating, try dipping in a very weak muriatic acid dip, about 2 seconds, then rinse and dip again in rubbing alcohol for 5 seconds, rinse and go in to the chromate. Let me know if that helps I will try that, but these results seem to suggest a connection problem and maybe a not enough current. Thoughts?

-

HLS30-07848

That was a first for me. Pulled the dipstick to see if there was water in the oil and water started pumping out of the dip stick hole... Dohhh!!!!

-

HLS30-07848

We have gotten the motor to turn over with a ratchet. I have worked on disassembling the SU's. Wow! I had a fit getting this piston out... The issue I have now is getting the throttle plates to move. If I could get them to move I could probably salvage these, believe it or not. But right now the plates don't even wiggle. Might try some heat tomorrow to try to get some movement...

-

HLS30-07848

-

510 Su's

This is how they sit at the moment. Plated all the hardware and polished the overflow tubes. They will need some straightening. The buffer took them away from me a couple of times. Sourced the heat shield from Z therapy and a few other parts. I am still missing a few things. Throttle return springs and the hex head screws for the choke cable ends... If I set the float heights, I think they would be ready to go on. Don't know if I have what I need for linkage...

-

Cody's Goon

On a separate note. I need some pointers on the rear hatch glass. We have a new rear window seal from Baz at Datsport in Australia. I need to get the trim off the old rubber seal. Then I need polish the glass and reassemble. Questions: Do I install the trim first like on a Z? Do I use a sealant under the weatherstrip? Do I use a string like on a Z? This is the trim. It snaps onto the seal somehow...

-

Cody's Goon

So we spent the last few weeks working on the hatch. It turns out it has been hit hard at some point. Right in the license plate. Some one did a fair job of reshaping it but it still needed work. We worked on it for a couple of weeks. I looked some at replacements but they were really expensive for some thing in much worse shape. It is really hard to get the crease lines right when you have no metal to guide you. I shot color on the inside a week or so ago. Color on the outside on Thursday and clearcoat on Friday Still getting tons of trash in my clear coat. I think I am going to redesign the booth to try to eliminate some of that. We cut and buffed today. Sanding on clear coat is down right spooky. I hate it... This is wet sanded 1200, then 2000 grit. Used a cutting compound then a polish at about 1500 rpm's This is where we ended up. 99% of the trash is gone. It's looks good unless you get really close and at the right angle All of the "orange peel" is gone. I didn't have much to begin with, which helped Buffed all the hardware and he reassembled the hatch. I had plated all the latch hardware over the last few weeks We will have to source new license plate lights because one of these is badly dented. I will also need to source the exterior hatch vent pieces...

- Cody's Goon

-

Loose seatback

The front is likely cracked from the rear being broken. The flexing broke the front right around the washer. The back looks broken from heavy people dropping into the seat repeatedly.

-

Fender removal

wd40 doesn't work as good as "Kroil" or "PB blaster". An impact screw driver would be my tool of choice. After that I switch to cutting tools and taps. They can be very hard to get out. The nuts on the bottom are welded to the cowl...

-

Old vs New

We have had the clutch issues with my wife's 350z. I will have to look into RJM Performance The clutch issues are even worse on the internal slave system cars

-

240z closed on BAT today

$11k! That's a lot of money for a rusty project!!!

- 1976 280Z Restoration Project

-

Front Suspension not settling

Is this the case with Poly bushings? He said he went Poly in the first post...

-

Deja Vu: 1971 Restoration

Beautiful as always!

-

Z31 N/A RB project

Now that's a great Christmas present!

-

#305 on Bring a Trailer

A very doable car. The floor boards are toast, but in my opinion the hardest part to fix on the whole car is that bad dent to the left of the rear hatch. The metal there is paper thin and extremely hard to weld or hammer on...

-

nice 71 in corvallis, oregon

Those bubbles in the paint mean it's not rust free!!!!!

-

Removing wiring harness for media blasting

It really isn't that hard to remove the rear harness and reinstall it. Use some stiff wire to help feed the harness back in. I would never leave the harness in for media blasting . They will destroy the harness...

-

Deja Vu: 1971 Restoration

That would be interesting to know! @Mike

-

My two swiss S30Z Fairlady Restoration build thread

@JLPurcell

Subscriber

Subscriber