Everything posted by Zed Head

-

1973 240Z Heater Control Panel

-

1977 280z Light Restoration Project

Was it obvious by eye? The color? Never really looked at mine when I had the head off.

-

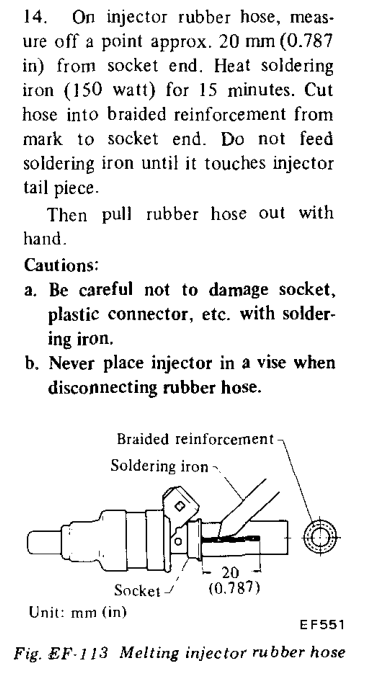

Getting Old Hoses Off Barbed Fuel Injectors

My 76 injector hoses looked okay on the outside but they were split on the inner diameter. You could see the tiny radial cracks. I smelled fuel one morning, pulled over, left the engine running and opened the hood and a tiny stream of raw gasoline shot past my head on to the sidewalk. I had a screwdriver in the car and cranked the clamps down to get home. The engine was cold, otherwise my car probably would have ended up like one of those in AV8's recent thread. On replacing the hoses - I used Gates EFI hose, and gasoline to press the pieces on, but I found that the material "creeps" over time on the clamped end. I had to retighten the hose clamps at the rail a couple of times. If I was doing it again I'd try to find some constant tension clamps.

-

1977 280z Light Restoration Project

-

1977 280z Light Restoration Project

This is the dilemma. 40,000 is not much. The question would be, what has aged, not so much what has worn. On the valve seats, I think that they might have went to the harder seat material for 77. I think it's in the 1976 Bulletin. Maybe somewhere else. Vague memory again...

-

Getting Old Hoses Off Barbed Fuel Injectors

Burn it like a bushing. Burn it! burn! burn!

-

Getting Old Hoses Off Barbed Fuel Injectors

Found this - https://injector-rehab.com/product/ferrule/ Answer to question not asked - I had a vague memory and found its source. It's in the FSM Engine Fuel chapter. One of those old wood-burning tools would work too, I'd guess.

-

1977 280z Light Restoration Project

Z engines are so easy to remove that this comment doesn't really have any weight. Looks more like a guy with a business trying to get some business. That's my first impression. Mechanics need to mechanic. As Mark M. says, inspect first, then decide. I've noticed that the high quality parts seem less available today. You could end up replacing good used parts with bad new parts. If it's not broke don't try to fix it.

-

resurrecting a 1977 280Z

I'd see if the noise is from the brake system alone or if it has something to do with the suspension being loaded. In other words, does it make the same noise if you press the brake and lift your foot, stopped, over and over again? Or does it only make the noise when you've rolled to a stop with the brakes on. Probably the second. Which implies that something in the rear has a load on it, that is released when you let the brakes off. First thought is the top of the strut in the tower. Or a sway bar, or a control arm bushing. That's three thoughts, but they're in order. I'd have a friend watch the rear wheels while you put the car in reverse and forward and move back and forth. Hit the brake a few times. Something will show.

-

Wheel Hub Differences

Seems like that lip might also grind away if the wheel bearings go bad. Might be why it looks machined. Why would you make a good one not-so-good, instead of just living with a not-so-good one? The lip serves a purpose.

-

Wheel Hub Differences

The hub rides on the bearings. So the bearing race seats and the seal seats are what matter on the inside. I think that the lip is protection to keep dust and dirt away from the seal. When you put it back together look down at the gap and you'll probably see its purpose.

-

Wheel Hub Differences

Do they look the same on the wheel side?

-

Wheel Hub Differences

Have you checked the edge of the short one for damage? I had a 78 hub that had that lip worn off due to a pebble getting trapped in the gap and grinding away. It didn't matter much because the seal seat was intact. Wipe the grease off and see if it's a machined surface or jagged.

-

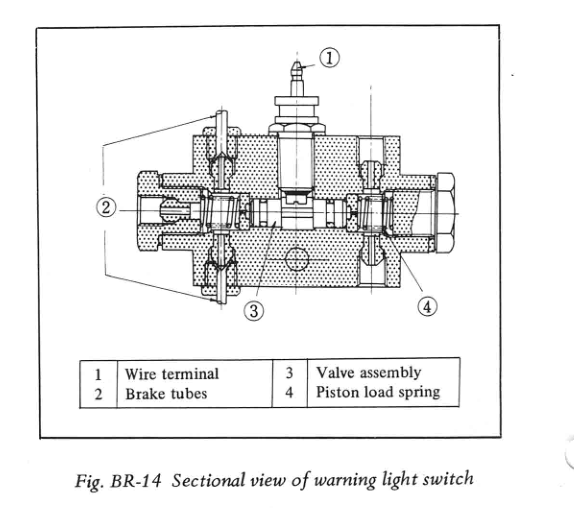

Booster & MC compatibility

The two switches just complete the path to ground for the light. The wire that goes to the warning light switch is probably shorted to ground somewhere. You'll have to find it. It's not a distribution block, it's just a switch.

-

Been absent sorta...

Seems like you have your priorities right. Good luck. Don't press too hard. Slow and steady on the big jobs.

-

saturday night music thread

These seem to fit together, but with some years in between.

-

Fuel Cutoff Switch

All of the ratings are shown. If you pick 4 and 5 as "good" and 3 or lower as "bad", you get a 70% good rate. Who wants that? Ford has produced millions of them. Not really seeing anything to argue about. Are you still going to use it? Imagine hitting a bump while driving and having the engine die. The safety device actually causes an unsafe condition. Sorry it had to be you. It's not personal...

-

Fuel Cutoff Switch

I'm just saying, Ford parts probably don't get these kinds of reviews. Amazon is full of cheap parts. I have a set of headphones that broke after a year and Amazon just "disappeared" them and the company that sold them from their web site. From the United States DGC 1.0 out of 5 stars It stopped working Reviewed in the United States 🇺🇸 on July 15, 2022 Verified Purchase This was the cheapest option and I should have spent more money. It doesnt necessarily feel bad initially. I tested it a few times and it worked like I wanted. I went to install this and of course it wouldnt reset anymore. Look elsewhere for a product Helpful Report david chappell 1.0 out of 5 stars Cheap quality Reviewed in the United States 🇺🇸 on October 26, 2022 Verified Purchase Broke immediately after install Helpful Report Joy V Pawless 1.0 out of 5 stars connector will not secure Reviewed in the United States 🇺🇸 on August 10, 2022 Verified Purchase The connector that plugs into the switch doesn't secure or lock in. I just trashed it. Helpful Report bobsled 46 1.0 out of 5 stars Very trigger happy Reviewed in the United States 🇺🇸 on July 17, 2022 Verified Purchase Mine tripped when I closed the car door. And I tried 2 of them. Buy something else

-

Fuel Cutoff Switch

Most Ford vehicles have inertia switches. If you want a high volume auto factory made piece. No offense to the Amazon parts but I'd rather have a used (by time only) Ford part than an untested part. Typically behind the kick panel on the passenger side. The red button is visible so that it can be reset. Salvage yards would have hundreds.

-

Fuel Cutoff Switch

The manufacturers are running out of names. "Hmknana"

-

Fuel Cutoff Switch

Your 77 should already have one in the AFM. When air flow stops the fuel pump power is cut off. Your fuel pump should not be running when you turn the key on. Only at Start and when the engine is running. That first picture shows a modified engine, with individual coils. It must have aftermarket engine management. But, on the topic, if you haven't already done it - the 1978 and 280ZX fuel rails are safer than the three piece 75-77 rails. The hose connecting the three pieces can leak. That first picture shows what's probably a 78 rail. One piece metal.

-

75 280Z -Tension rod poly & rubber mix - which side should keep the rubber - Leading or Trailing Side (of mount)

The poly in front will stop the control arm from moving backward on braking. It gives more precision to the steering. That's its only real purpose. It started as a racing thing, people saw a market, and started making poly parts for anything that was rubber. If you put poly in the back it puts side force on the tip of the rod as the suspension moves. The rod actually changes its angle through that mount as the suspension moves. You can move it by hand and see what happens. Since yours is apart you could assemble the rod and mimic it. Eventually the metal will fatigue and it will break off. It will also creak and moan when you go over bumps. It happened on my 76. That was with old rubber in the control arm bushings. Some people have said that they put poly everywhere and did not have any problems. So it might be that the mix of poly and old rubber creates a problem. And, finally, some people have drilled holes in the poly to reduce its overall stiffness. But, of course, that just makes it more like rubber.

-

Other early OHC straight sixes

I had a Pontiac GTO in my early days and knew several guys with Firebirds. I'd heard of the Pontiac Sprint 6 but never knew much about it. Found this article today. It's an OHC but the cam is in the valve cover. Pretty crazy. It was a big engine too. 250 CI versus 146 for an L24. Straight six with a Quadrajet. https://www.hemmings.com/stories/article/inside-the-sprint-six

-

Overfilling diff?

Oil expands quite a bit with temperature. Could be a factor. If the PO raised the back end that would also allow a little more in.

-

Image upload not working this evening?