Everything posted by Zed Head

-

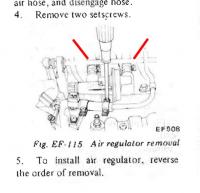

Runs rich and high idle after restart

One important fact here is that the potentiometer can only make the mixture richer. You can only add resistance to the CTS circuit. The only to reduce resistance would be to add a resistor in parallel and that would change the shape of the enrichment curve dramatically. This thread started with the comment that "it still runs very rich". The actual parts being used haven't been fully described (in this thread, maybe in another). You said the injectors were replaced 500 miles ago. Did you replace them because of the rich-running or did the rich-running happen after replacement? Did the engine run okay before the work? What brand/model of injector are you using? Maybe someone gave you turbo injectors, which are of a higher rate. - - - Updated - - - One important fact here is that the potentiometer can only make the mixture richer. You can only add resistance to the CTS circuit. The only to reduce resistance would be to add a resistor in parallel and that would change the shape of the enrichment curve dramatically. This thread started with the comment that "it still runs very rich". The actual parts being used haven't been fully described (in this thread, maybe in another). You said the injectors were replaced 500 miles ago. Did you replace them because of the rich-running or did the rich-running happen after replacement? Did the engine run okay before the work? What brand/model of injector are you using? Maybe someone gave you turbo injectors, which are of a higher rate.

-

Got hit Friday night

You can't really say it's dumb with the information given. Anyone who's dealt with insurance companies knows that there are multiple ways to get screwed over and if the situation is not clear you can get in to an extended frustrating battle to get things right. It might be obvious to the two parties who's fault it was, but if siteunseen had his nose over the white line or it was dusk and his lights were off or etc. the insurance company could make life difficult. Besides that, maybe he was just being a nice guy. Many would also argue that 1977 is not a classic. But that's in the mind of the beholder anyway, in all cases. Forgot to say that, apparently, those rubber pieces are available from Courtesy Nissan. $84.67.

-

LSD question

LSD's have a clutch or mechanism of some kind in the carrier (the center structure with the small gears in it) to distribute force to the wheels, where in your picture you just have four spider gears (the small gears). That's a good picture because it shows the spider gears and their shafts, no clutch. People do weld the spider gears together to make the wheels turn together. Most load up with lots of weld material but it's probably not needed. The one in your picture could be welded even though it's not obvious. Here are some links with pictures of R200 CLSD's. An R180 or R190 would look similar. The second and third pictures are the best because they show the ramping mechanism (the diamond shaped piece) that distributes the force through the clutch. Nissan OEM 3.90 R200 LSD Diff Limited Slip Differential Clutch Type Datsun 240Z 260Z 280Z 280ZX 300ZX Z31 | Whitehead Performance Datsunracing.com Image Gallery :: My '73 240Z :: lsd http://www.nengun.com/nismo/nissan-motor-r200-lsd-for-mechanical-177132

-

LSD question

You didn't ask a question and you posted a picture of an open diff.

-

Headlights not working

Pretty common, also, for the ground side to get gummed up. There are two switches - one to supply power and the other to provide a ground. It's the high/low dimmer switch in the turn signal assembly. I've fixed two by squirting contact cleaner in to the switch and working it. I've also fixed a power switch by tightening the little tabs on the side of the circuit board (two circuits). It's on top of the column. But if you have the column cover off and you're there it might be worthwhile to bend the tabs back and take it apart. The contacts get pitted over time and can be cleaned up. Watch out for the little parts and remove the power source first.

-

Replace whole ignition switch, or just the rear electrical connections

Unplug the switch and see if the problems go away. The assembly is two parts - key and tumblers and an electrical contacts switch. There is a small rod between the two that transfers the key twist to the contacts. If you take the switch off, you can unplug the electrical part and actuate it with a screwdriver. If your switch has never been off you'll have to deal with the headless screws. The screwdriver slots are designed so that thieves can't easily remove the switch.

-

Need information on E31 head/head gasket dimensions

Looks like you need an o-ring that will fit inside the gasket hole but not clog the port. The oil port is much smaller than the actual headgasket hole, it's tiny. Any standard shape o-ring that fits inside the headgasket hole won't clog the small oil port. I would fit the eyelet and o-ring to the headgasket and not worry about the block or head. And as madkaw suggests, you might not even need an eyelet, the copper crush ring will do the job. OR, as I've seen recommended, you could just carefully apply some RTV to the oil port area. Do the water passages too while you're at it. Edited - added a picture from my N42 L28. you can see the oval outline of the copper (in the HG as noted below). The port in the head is big but the orifice determines the flow.

-

Two post lift points for the 240?

I've pondered just building some fixtures that mimic the shape at the top of the factory scissor jack and using the scissor jack lift points on the rocker panel of the car. Basically a piece of square tube with a slot cut in it. Easy to get to and under what should be one of the strongest structures of the body.

-

Bronze valve seats?

So far I've been ignored but what the hell... Eddy67 is looking to find the head that will give him a performance boost over the stock E31. Seems like the bigger valves of the N47 should provide more flow, giving more potential. Whether or not the rest of the parts can realize that potential is unknown. The carbs would need some work, I assume. The cams are similar, if not the same grind. The round ports will be dumping in to square exhaust ports, so should be okay. But, the important question of valves hitting the edges of the cylinder seems to be in play. If he can avoid or fix that problem, and is ready to retune his carbs, then the N47 seems like the way to go. BUT, it seems that the round N47 ports might be larger than the square exhaust manifold ports of the manifold used with the E31 head. Another thing to fix. Carbs on N47 - Nissan : Datsun ZCar forum :Nissan Z Forum: 240Z to 370Z Everything still leads back to just using the bronze valve head. It's not going to die in 2500 miles.

-

Replacement washer fluid pump "How To"

Isolate problem to smaller area > unplug pump, press button. : if fuse blows then problem is not on the pump side of the plug : if fuse does not blow then problem is on pump side of plug.

-

lowering the Z

He's calling himself "slammsun". He'll probably put "Heelys" on his crossmember...

-

Bronze valve seats?

You can tell things are slow when you're trying to convert a guy who just wants to replace his excellent shape valve seats for something more durable in to a race engine owner. Not that there's anything wrong with that. He could probably run the bronze seats for 20k - 30k miles while he works on the other head.

- 240z 1973 tachometer show +- half of real rpm

-

Runs rich and high idle after restart

I'm going to guess that somebody removed yours. The block would be mounted using those two bolt holes, but with longer bolts. A sandwich. To remove it you'd just use shorter bolts. The block is ugly and a real pain to get the coolant lines connected, and is a potential leak source. Not a big deal if the power to the internal heater still works. It does take about 40 seconds or more to fully close the valve using just electrical power though. You can pinch either one of those hoses shut to see if it's the valve staying open that causes the high idle, as siteunseen suggested. If the hoses are old though, they might split. Then you'll get a really high idle that never drops. On the BCDD - it lets air past the throttle blade like the AAR does. Whether it would cause a high idle at start would depend on if the passage is normally open (closed by engine vacuum or the solenoid) or normally closed (opened by the solenoid or vacuum). You'd have to study the Emissions chapter to know.

-

Anybody the middle part from the rear bumper for sale ?

Maybe Black Dragon will sell one part of the set - Datsun 240Z, 260Z, 280Z, 280ZX & Mazda RX7 iCatalog - Black Dragon Auto

-

DaZed & confused in Portland

Z cars are notorious for poor idle voltage. I would run the bigger pulley if you can. But the timing chain cover on the L24 engine that you're going to use is probably set up with a single pointer, to be used with the multiple mark pulley. The L26 with the bigger pulley (probably bigger to fix the voltage issues) and one mark is designed to be used with a degreed timing marker. Timing read from the marker versus timing read from the pulley. If you can put the L26 timing marker and damper/pulley on the L24 engine, that would be the way to go, I think. The timing marker on the cover might be a simple swap. Swapping dampers might take some work, although it looks you already have one removed.

-

Runs rich and high idle after restart

The drawing is from the 1975 FSM. Odd. A picture of the top of your manifold would be illuminating.

-

Bronze valve seats?

There's others that know more but maybe you got a bad casting. If the sand you found came from the casting process that means the investment (probably wax back then) might have been damaged. The coolant could be coming from a leak between the cooling channel and the intake runner. Check the inside of that cylinder's runner. The head might be no good from the factory. Guys that port their runners sometimes over-do it and cut in to the cooling channel.

-

N47 head header QUASTION

N47's have the round exhaust ports.

-

Runs rich and high idle after restart

siteunseen makes a good point. The AAR's tend to get gummed up. I can't find a specific reference to the heating block but I did find a picture. I added red lines to indicate the inlet and outlet coolant lines. Check your coolant temperature sensor resistance at the ECU connector and compare it to the chart in the FSM. You might have dirty connections somewhere, raising resistance.

-

Runs rich and high idle after restart

If the idle speed changes when you remove the hose odds are it's working right. If you measure pressure with the hose on and off it will tell you a lot. Numbers are always good, "right on" just means that you feel good about it (no offense). The AAR came from the factory with a heating block under it, with coolant lines attached. If yours is gone, the AAR will not get as warm as designed and stay open. Could be part of your problem. You didn't mention the power line to the AAR. You can check power with a voltmeter, it should have power when the engine is running. It's on the fuel pump circuit.

-

Runs rich and high idle after restart

The high idle sounds like your AAR is not getting hot and staying hot. Do you still have the coolant line running to the mounting block for the AAR? That's what keeps it warm. And the power line to the AAR warms it up when the coolant is cold. On the rich running - have you confirmed that the fuel pressure drops with intake vacuum? You can have spot-on pressure, not running, but be rich running if the FRP is not adjusting pressure.

-

Spindle Pin Woes

A design that spins the pin while pulling might have some benefits. When the pin is pulled straight out the rust particles can wedge in the small spaces, and the high spots can gall the points that they can't get past. Spinning allows things to find their happy place, along with doing a little grinding on the high spots, and lubing up every surface. I had good luck threading old mag wheel lug nuts on to each end of my pin and spinning the pin while beating it back and forth. It got looser and looser until it could be punched out with a long bolt.

-

Bronze valve seats?

Just realized that my other post was incorrect. The FSM describes reaming the head to to the proper size to fit the seat. And the interference fit spec. is at the end of the chapter in the specs. section. Recommended temperature for inserting the seats is in the chapter also. Too many numbers to piece-meal them out. Good luck. Index of /FSM/240z

-

Bronze valve seats?

The replacement procedure is described in the Service Manual. It doesn't look too complex. They recommend boring them out, heating the head and pressing in the new ones. No tolerances given but maybe there's only one size and the hole is assumed to be untouched. After they're installed though they need to be ground to fit the valve. That's the part that takes the skill and is most important. If you're not going to grind them too you might as well have a shop do the whole job. You said you're a machinist so may know that but just in case...