Everything posted by Zed Head

-

83 280ZX accelerating problem

Doesn't really fit your acceleration weirdness, does it? No pickup from idle to 2000 RPM with six sparks, and awesome acceleration after 2000 with five? You're testing for spark with a timing light or tester of some kind?

-

Buying My First 280Z

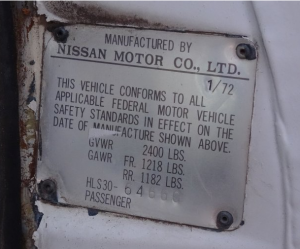

If it is the same car, the nickels and dimes will flow for a longtime to get it in to decent shape. Every little trim piece is probably costly, especially for the 240Z's, and is hard to find. Could be a fun project but you probably won't be driving it much for quite a while. Doesn't the VIN plate look a little beat up? Makes you wonder.

-

Timing indication

Since "R" is after TDC, and A is before TDC, when the marks are as shown, timing should be at zero, not 5 degrees.

-

Project Boondoggle (or, so I went and bought a Z!)

Looks in good shape. Two sources you'll want to at least open and browse through are linked below. Engine Fuel chapter in the first, and the second is a collection of tests covering many years, in the Guidebook. Get the 1980 book, it covers all. There aren't really many people out there "qualified" to work on these old EFI systems. If you know the basics of an engine and how to use a meter you might be best off to do your own work. http://www.nicoclub.com/FSM/280z/ http://www.xenons130.com/reference.html

-

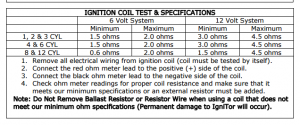

Need to replace Pertronix Flamethrower coil

This is probably the Ignitor kit that you have - http://www.summitracing.com/parts/pnx-1741 And these are the instructions - http://static.summitracing.com/global/images/instructions/pnx%20ignitor%20i%20tests.pdf which say that you want 3.0 to 4.5 ohms on your coil circuit. Resistance is added in series so just add the resistance of the coil to the resistance of the ballast and make sure that the sum is between 3.0 and 4.5 ohms. Since you have a 3.0 ohm coil you can remove the ballast and run the coil without it. You'll be at 3.0 ohms, which is in spec. and will give the hottest spark. That's what I would do.

-

83 280ZX accelerating problem

Sorry, I got my years mixed up (again). Your engine has a cylinder head temperature sensor (CHTS), in place of the coolant temperature sensor used on the 280Z's. It's on the right side of the engine, above the spark plugs, between 5 and 6 I believe. Same style of connector, and you should fine the bullet connectors, I think. As site said, a vacuum leak after the AFM would cause a lean condition also. Easier to find and fix that, if that's the case. Even the PCV system, the hose underneath the intake or the one from the valve cover, can cause a lean condition if it leaks.

-

Some FSM and Carparts Distributor Data

I've found several 76 and 77 distributors with 11 stamped on the slotted portion (the cam, I assume it's called). Not sure the FSM is 100% on what actually came in the cars. Assuming the stamped numbers are the maximum centrifugal advance. Has anyone ever determined what the typical CARDONE rebuild distributor has? They show the same distributor as compatible with many years. They must have chosen some middle ground.

-

condenser on coil positive is important.

I thought the tuned circuit part was for points, along with suppressing the arcing to make the points last longer. Not sure that the same applies to transistor ignition systems. Arne's problem was with a Pertronix electronic setup and it was never really clear why his had problems but numerous other people with the same setup didn't.

-

83 280ZX accelerating problem

Click a few times. It's called "Fuel Tweaker". Radio Shack restructured, but didn't liquidate. Dallas is probably big enough to support one. How's that for "dead"?

-

condenser on coil positive is important.

Is that Buddy Holly's garage?

-

Need to replace Pertronix Flamethrower coil

Describe the rest of the ignition system. Do you have the Pertronix ignition module? Or points? Or something else. That will determine, for the most part, what resistance you need on the primary circuit.

-

83 280ZX accelerating problem

One problem people new to cars have is terminology, not enough words in their brains to convey the message. Reading back through your post I think what you might be describing is a "lean" fuel air mixture. Not enough fuel for the quantity of air entering the engine. It's controlled by the AFM vane position, so will be tied to engine RPM. But, before you go crazy on the AFM, one cheap thing you can try, that might be enough, is to add resistance to the coolant temperature sensor circuit. It's fixed the problem for many of us here, and it's pretty simple. You can either buy a few resistors and wire them in or get a cheap potentiometer (volume control) from Radio Shack and use it as adjustable resistance. The sensor has a bullet connector on each wire coming and going to the ECU. Put a male and female bullet on your resistor, find one of those connections, and slip it in there. If "lean" is the problem, a little bit of extra resistance will have immediate effect. If it does, you can focus on fuel supply - fuel pressure, clogged injectors, bad AFM, etc. At least it wil give you a better focus. And the second "Bible" is really the one you want. It might be available from another web site somewhere, or maybe you can find a way to get it on a thumb drive or something. It covers the ZX's. http://www.xenons130.com/reference.html

-

Zinc Additives, Cam Shaft Or Rocker Wear, And Mileage - A Poll

Bought six quarts of 10W-30. For a future break-in.

-

260z won't start!

Crap, I knew something was bothering me when I posted that. I usually point that out myself. The picture I posted is from the wrong FSM. Got 73 stuck in my head, not 74. Forget about points Clomolina. You can still check air gap though. Engine Tuneup chapter. http://www.nicoclub.com/FSM/280z/

-

260z won't start!

The stuff below is wrong for 1974. See the two posts below this one. No the points are under the cap. If you don't know what points are, that's not good. You have much to learn. Anybody who has worked on older cars, will know what points are and how to check them. Newer cars don't have them and many people have never seen a set.

-

260z won't start!

That's not really the best way to check for spark. Put a sparkplug in the wire and place the body of the plug, the threaded metal portion, in contact with the engine, typically the valve cover, where it can be seen. Then crank the engine while watching the plug for spark. Be careful, the engine might start, so put the plug and wire where they won't get damaged if it does. That's one way, there are others. Have you checked the points yet? Examined the inside of the distributor cap? You're jumping around a lot, hoping the engine will start but you should really be going through the basics first to make sure everything is in order. If the PO left the fuel pump disconnected, who knows what else is missing. It may not even have a rotor under the distributor cap.

-

Timing indication

Don't you have the original marks on the pulley? Several. And the pointer. How did you determine TDC? You can get a lot of crankshaft rotation for not much piston movement.

-

83 280ZX won't start, won't fire. Just turns over.

No, it looks like you have the right distributor for the engine management system. No CAS for NA. And the problems you described are all common to old distributors.

-

Zinc Additives, Cam Shaft Or Rocker Wear, And Mileage - A Poll

That's cheap, in general, for any oil. Hope it's not a discontinued product price. Thanks for the tip.

-

Rear shock noise

You're in the MSA vendor forum. Not the best one fro fixing problems. The springs will compress when you put the weight of the car on them. They just don't have any preload. Can you give more detail than "Lately I've be hearing a clunking/popping noise"? Noises from the rear have many potential causes.

-

Seattle Area Z Brunch Saturday

I had that same thin stream of fuel shoot out on to the sidewalk when mine finally let go. Mine was squirting from the connections of the three piece rail though. Note on the newer EFI hose. It tends to creep or relax a little bit over time. At least my Gates brand hose did. I think the newer hose is designed for constant tension spring clamps, not the screw type clamps. Might need to retighten the clamps occasionally until it settles in. That's VR-1 oil, right?

-

tranny question

We had a big discussion about this quite a while ago. There's internet stuff that says the numbers mean something but when you compare the numbers with known facts about the transmissions, like year of car they came in, there doesn't appear to be any usable correlation. You can tell a lot just by the gear ratios.

-

Driveshaft play at transmission end. Normal? (see video)

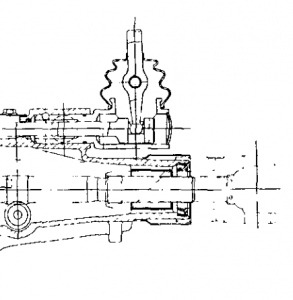

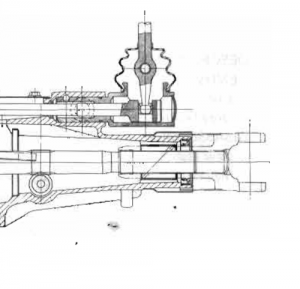

Just a couple of things. Maybe we should go with factory nomenclature. That would be "propeller shaft" for the shaft we're talking about, and "drive shafts" for the two that go the the wheels. Some people use "tail shaft" to talk about the output shaft of the transmission, and tail shaft housing to mean the rear case of the transmission. On the measurements. I measured in exactly the same spots as EuroDat, center to center of the u-joint caps. early 240Z propeller shaft - 21.25" (540 mm) 1976 280Z shaft - 22.3" (566 mm) EuroDat's late 204Z shaft - 22.55" (573 mm) As for room inside the slip yoke for the transmission output shaft, the early shaft, I measured 4 11/16" by sticking a tape measure inside and eyeballing to the end of the slip yoke. 4.6875", 119 mm. Just to give some idea of engagement. But, I'm not sure what hits first, the output shaft inside the yoke, or the nose of the yoke on something inside the transmission. Also added a picture fro the 1976 FSM showing the yoke inside the transmission and what looks like an outline of the bearing. You could easily be only half-engaged in that bearing. It might be wallowed out already, damaged. Edit - also added a much better image from 1973. The best route might be to remove the shaft, examine the inside of the transmission for damage, and get a longer shaft. Might be overloading on data here, but it's fun to review all of this since I spend a bunch of time doing the same for the 71C case swap in the past. Which is still sitting in the garage.

-

Driveshaft play at transmission end. Normal? (see video)

I get 21 1/4" from cap center to cap center on my early, diff-forward shaft. It's not clear what "stock" means, and I don't know what shape the mustache bar was on the diff-forward setup, but it looks like you have the short shaft, when the long one would work. MY 280Z long shaft is a hair over 22 1/4". Looks like you have the short shaft when you could use the long one. I look at the angle of the halfshafts to determine if the diff is forward or not. In the improved vibration resistant setup (the factory modification and what they changed to for later cars) the shafts are perpendicular to the wheels when looking through the wheel well. In the early cars you can see that the shafts are angled forward. Did you try wiggling the yoke around like in your first video? That would answer part of the question. If the play goes away, then a longer shaft might be more stable. EuroDat mentioned tailshaft in his post. I don't know if he meant your transmission, but there are shorter versions of the 71B transmission. from trucks. Maybe you have one of those. Obligatory edit - to be clear, you do have the R180 diff? It hasn't been swapped to the R200.

-

Rocker Revival

Here's an old article. People have wondered about this for a while - https://books.google.com/books?id=CRDEneSREucC&pg=PA144&lpg=PA144&dq=smooth+tappet+surface&source=bl&ots=7Hum0yt51O&sig=DgXG_t_DAzbCNCNPCEvDyp7C-x0&hl=en&sa=X&ei=-AIzVd2fAoO3oQTo2IGwCA&ved=0CCQQ6AEwAQ#v=onepage&q=smooth%20tappet%20surface&f=false