Everything posted by Zed Head

-

Flow Rate and P/N Of Original Factory Injectors

My impression has been that it's just an old out-of-business aftermarket supplier, or maybe even the supplier to a supplier. You might have more luck just looking at injector images, but I'll bet that at some time in the past, pre-internet society, when you went to Autozone or Oreilly or one of the others and bought Brand X injectors, you got those injectors and the "RAM" is just an artifact, unconnected to the brand name of the supplier. Random Access Molding maybe, did the injection molding for the plastic portion.

-

Transmission internals question

They do seem exposed. The ends of the shift rods are all stopped by the front cover. You might make sure that all three rods are on the same plane and see if the inserts are still exposed. Could be that the coupling sleeve is just moving farther than it will when everything is fully assembled.

-

Transmission internals question

The synchro that you're looking at is the 5th gear synchro. I haven't really studied the way that Nissan added 5th gear to their 4 speeds but it looks like they made the reverse gear in to the coupling sleeve for 5th. Pretty cool. When it's uncoupled to 5th it's used as reverse. Dual usage. Never realized that. 5th gear will be engaged when you're cruising down the free way at 60 mph and those parts are rotating. Not sitting, with no rotation. You might be making much from not much.

-

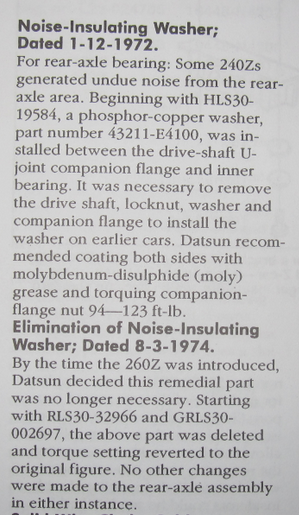

Lost Rear Bearing Shim Washers

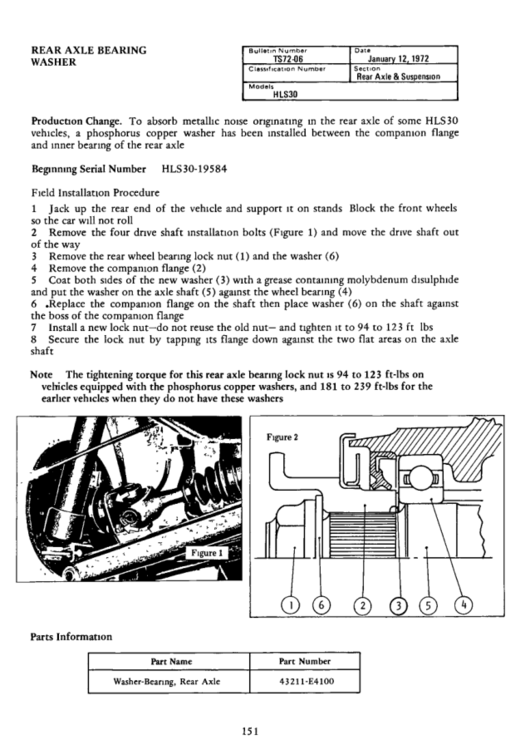

Here's a snap-shot of the actual TSB from the compiled volume that the "Canadian formerly known as Blue" uploaded. It's in the Manuals section but should be in Service Bulletins. You'd have to know what type of noise they were trying to reduce, to know why they chose a copper washer to serve the purpose. They say metallic. Could be a clank, or a clunk, or a high frequency noise. I'm going to guess it was clank-related.

-

Transmission internals question

@Dave WM and @EuroDat have been deep in to the 5 speeds. They might have some thoughts. You might be looking at 5th gear. Reverse does not have synchros in 1983, it's the straight-cut gears. Reverse and first are the only two gears where shafts might not be rotating when shifting. All of the others will have the output shaft rotating with the propeller shaft. Without oil things do tend to get sticky. When you put it together make sure that it's not locked up after. It's possible to get it in to two gears at the same time when putting the front case on, because the shift rods will move. Most people put it in to a certain gear like 2nd or 3rd then put the case on.

-

Car wont turn over

Since you know that the engine will start and run, but your problem now is getting it restarted, and keeping it running, I would not do anything drastic. Focus on getting the right things done in the right order so that you don't get lost in unnecessary details. If you do decide to do "while I'm here" things or things that will need to be done eventually make sure you get them done to completion or you might end up with things torn apart and a bunch of new puzzles to solve. The starting system is essentially independent of everything else on the engine and car. The starter is connected directly to the battery, and is controlled by the starter solenoid. You can work on it independently of all of the other things you're looking at. Can't tell you what exactly to do but that's how I would look at it. You should be able to easily get the engine to spin using the starter, if you're battery is charge. "12.5 to 13" implies that you're using the dash gauge to measure voltage though, and it's not accurate. Get a real meter, you'll need it. Your alternator ground wire is in the wrong spot but it is probably not a big deal. "E" stands for earth, which is also called ground. But the alternator case is also connected to ground. It looks like your T plug has been messed with. Take that white piece of tape off and see what's under there. Your fusible link ends look like they need cleaning. Be careful that you don't short your battery when working on the electrical stuff. Take the battery negative cable off if you're not used to working on electrical. Burnt wires would be a nightmare for you. Those are bad battery cable ends also. They get dirty easily. Could be part of your problem. Good luck. Take your time. Take notes. Record numbers.

-

water spots in wax question

I would give it a good buffing with a soft pillow.

-

Flow Rate and P/N Of Original Factory Injectors

Googling around just now, I did find this - http://www.ebay.ie/itm/6x-RAM-Fuel-Injector-For-485cc-NISSAN-Skyline-RB30E-280ZX-300ZX-Z31-High-Flow/171746383140?hash=item27fce1d524:g:UTgAAOSweGxZc4v7

-

Car wont turn over

Congratulations on the new-to-you 280Z, and getting it started. Considering all of the facts, a bad or dirty/corroded starter seems possible. Assuming that the engine is okay. When the engine died did it stop immediately or did it die slowly? Are you sure that the engine is not seized? Try turning it over by putting the car in gear and rolling it, or using a wrench on the crankshaft or timing sprocket bolt. If the engine is free but the starter just doesn't have the juice to push the bendix out and turn it, you might remove the starter and clean it up. It's pretty easy to do. You can also remove it then reconnect the cables and test it off the engine. Make sure that you get the cables connected correctly, Nissan did not use red and black like everybody else did at the time.

-

Subaru differential stub axles

The silverminemotors.com link in Post #6 of Abate's thread is about "Datsun stub axles" for the Subaru R180. John Coffey designed them and saw them through to production then gave the info to Wolf Creek Racing. Not sure how Silvermine came in, unless they just made a copy. Here are two links in one, Wolf Creek and a link to the relevant Hybridz thread. http://www.wolfcreekracing.com/index.php?option=com_content&view=article&id=22&Itemid=31

-

Flow Rate and P/N Of Original Factory Injectors

I can say that I've seen the "RAM" injectors before. They were part of a mixed set on a used engine that I bought. I think that they're aftermarket, not one of the big OEM's. Pretty sure that mine were black though. I threw them away, they were in really bad shape.

-

Lost Rear Bearing Shim Washers

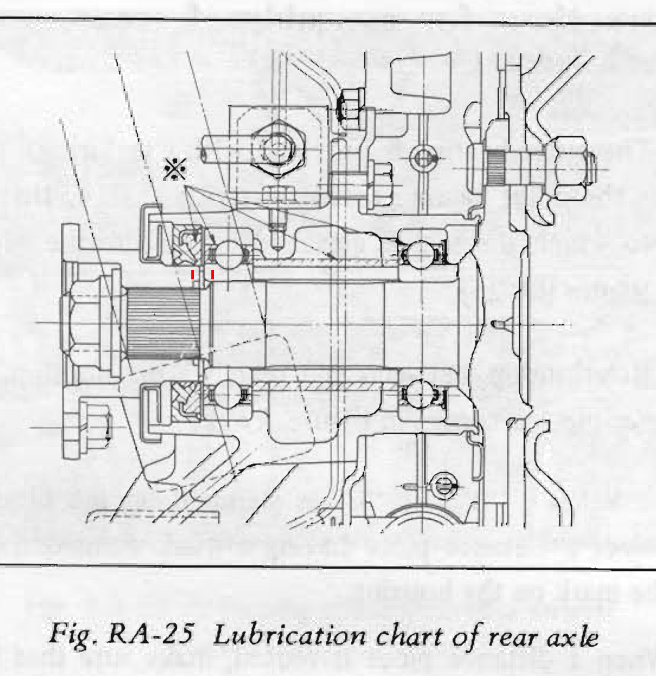

Not sure what washers are shown in that diagram. Here's the TSB's summarized from Humble's book, and the 1972 diagram showing no washers at the distance piece, but a thin washer at the bearing. Between the companion flange and the inner bearing race. The 1970 diagram doesn't show any washers, last picture.

-

Low miles, original paint 280z

Naysayers and potential buyers aren't the same thing. Kind of pointless to respond to the naysays. Just saying...

-

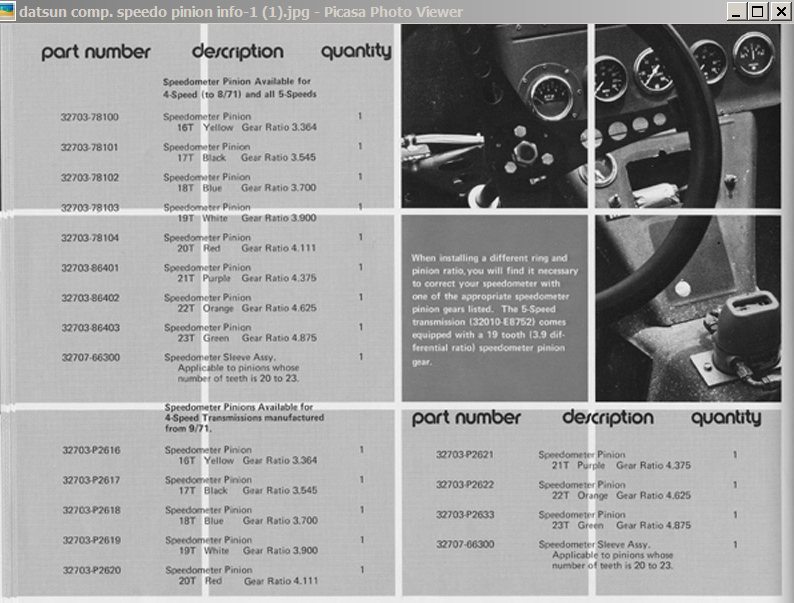

Tranny Speedo tooth gear housing swap - 280z 5 speed

Shorter answer - somebody either swapped the high tooth number sleeve in to your 280Z transmission, or they swapped the high tooth cog in to your 280Z sleeve. Either way, the 280Z sleeves are very common so you should be able to make the 18T cog work. But your question can't be answered until you know which of the two possibilities you're dealing with. A picture might help.

-

Tranny Speedo tooth gear housing swap - 280z 5 speed

For some reason clicking on your link only opens the same post again. I managed to trick it though. Looks like the 4.11 to 4.875 diff ratios use those cogs, probably why nobody sees the sleeves. Weird that you would find one in your transmission. You should have the correct sleeve in that transmission. You could insert the sleeve and cog while turning the propeller shaft, in neutral. It might be that somebody put the wrong cog in the right sleeve. Odds are that the sleeve you have is correct for the 18T cog, since the other sleeves are like unicorns.

-

Lost Rear Bearing Shim Washers

I was going to say what zKars said. Nissan has a TSB about their discontinuation. It's shown in the back of Humble's Restore book. Best to mic the hub and the spacers anyway to be sure they aren't worn or haven't been switched in the past. Kind of like "blueprinting" your hubs.

-

Anyone Have Subaru Output Axle Reviews?

You should post the details of this "failure". It's not clear what failed. "Shaft" can mean the diff stub axle, the u-joint half-shaft, the CV axle, or even the hub axle depending on who's talking. Axle and shaft get used pretty much willy-nilly. http://www.silverminemotors.com/datsun/datsun-240z/drivetrain-17/lsd-r180-sti-out-output-flange-conversion-stub-axels https://zcardepot.com/r180-subaru-axle-set-to-930cv-joint-new.html

-

Duffy's 1/71 Series 1 240z build

One reason not to do the wheel hub flanges is because they see much higher flexing loads. Side to side. And the lever arm of a wheel is much longer than the half-shaft flange. The half-shaft flanges only see rotational forces, for the most part, the side loads are just pulling or pushing the shaft longer or shorter. Tiny compared to the wheel loads. This topic came up a week or two ago and somebody told a story about their trailer wheel falling off because the painted flange let the lug nuts loosen up. I wouldn't paint mine. If you've ever had a wheel fall off once, you'll avoid a future occurrence at all costs.

- Duffy's 1/71 Series 1 240z build

-

Duffy's 1/71 Series 1 240z build

I think that it depends on the type of coating. If you've looked at the factory half-shaft flanges you'll see that they're painted by Nissan, on the mating surface. I've scraped a few clean when chunks started coming off, to be sure the surface was flat and consistent. The Nissan paint might be a two part thermosetting type of paint (I've never tested it for solubility - something to do), which won't melt and flow when hot, or creep under pressure. Paint from a spray can would be a solvent-based paint, which will melt and flow under heat and flow slowly (creep) under load. Be aware that there are thermoset and thermoplastic powder coatings. Two different types. The key is knowing what the properties of your powder coat are after curing. Epoxies will be thermoset and probably fine, nylons will be thermoplastic and maybe not so good.

-

Datsun 280zx won’t start

The fuel pump only gets power when the engine is running, when the key is at Start, and, if it's working correctly, a 5 second stretch of power when the key is turned on. It does not just keep running when the key is at On/Run. You didn't hot-wire the car you just moved the ignition switch. There are two fuel pump relays, one's called the fuel pump control relay and the other is called the fuel pump relay. My impression has been that they're both metal but who knows. There's a diagram and chart in the FSM, EFEC chapter. Theft prevention devices have been around for a long-time. I assume that colored blob picture is the back plastic-isch thing? Can't really see any of it. From your knowledge level it would probably be best to go back to trying to start it with starting fluid. That will define a good starting point for your other troubleshooting. You've changed some things since it last ran and you might have lost spark or timing conditions that would let it run when it does get fuel. If I was in your shoes, I'd confirm that it will run with fluid, make some best guess changes, and if they don't work reset everything and make sure it runs with Starting fluid. If you don't really know the basics you need a good baseline to go back to, to reset. Try some things, reset to "runs with fluid", try some more things.

-

Datsun 280zx won’t start

Will do! We need more "do" jimmyb. Dave F could do some browsing too. There's no CPS on the NA models.

-

Datsun 280zx won’t start

The ECU is very sensitive the its signal from the coil negative post to the pin on the harness at the ECU. You need to confirm that that path is clean and useful, as was said several times above. Could be that engine started on CSV fuel, which turns off when the engine is started, or when the valve gets hot from its internal heater. I've found also, that spark can be visible outside the cylinder, during a test, but too weak to start the engine. In my case, starting fluid would start it but it wouldn't light up on gasoline. You might also have a giant vacuum leak. "Nothing" doesn't tell much. No spark, no change in timing, no engine start....? The answer often lies in the tiny details. The FSM Electrical chapter probably shows where all of the relays and fuses are.

-

32K mile 1976 280Z Original - Survivor

I was going to refer to this thread to give the "what's it worth" thread some real and recent numbers. It's "gone" but did it sell or was there a reserve? BAT doesn't show sale prices apparently. Couldn't find one.

-

help with battery hold down

The clamps that fasten to the ledge on the bottom of some batteries are pretty nice. Less clutter, and the design is used by many OEM's. You'd have to some small fabricating to make it work on the stock try.