Everything posted by Zed Head

-

Electro-phile Follies, Vol.2

It might well be that ensys doesn't realize the effect his writing style has. Plus he's still worked up over the inability to post images. But, still, a problem was solved.

- Electro-phile Follies, Vol.2

-

"77 Z issues with KYB + VOGTLAND lowering springs

I was actually asking madkaw. But your info is good too. Do yours fit the perches? @Soedward11

-

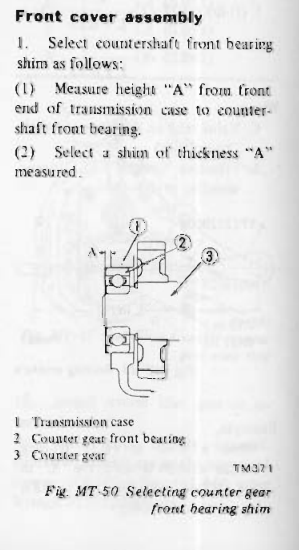

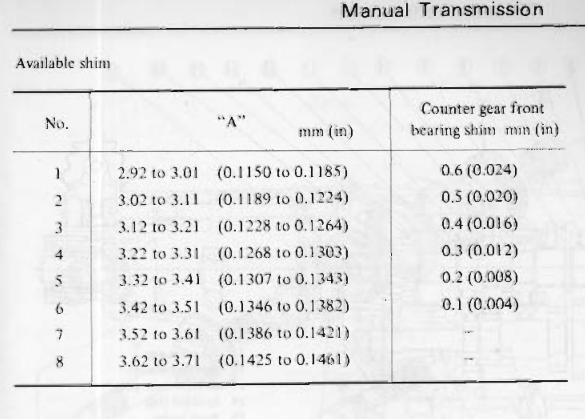

5 Speed Transmission inspection and possible rebuild.

Just thought of this - don't lose the preload shim in the countershaft bore in the front cover. It might be stuck in there, hidden, but you'll need it and the odd sizes aren't available anymore.

-

"77 Z issues with KYB + VOGTLAND lowering springs

Bummer. Who did you order them from?

-

5 Speed Transmission inspection and possible rebuild.

Here's a good read about doing transmission work. It also shows a sealed bearing used on a 71C transmission. Looks like it came from Nissan that way, the guy bought a brand new 240SX 5 speed. It's the front main shaft bearing though, which wouldn't see much fluid splash probably. He has some good tips for reassembling. Put the transmission in gear before reassembling otherwise you can get two gears engaged at one time as the shift rods are accidentally moved. This is where I learned about Hylomar Blue also. A non-setting sealant. http://zhome.com/ZCMnL/tech/240SX5spd/transmission.htm

-

New owner

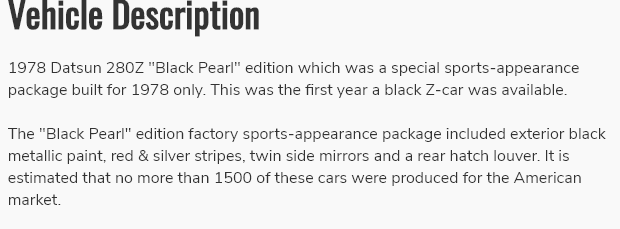

If you can find an area of paint that has metallic black then it was a Black Pearl, apparently. Probably what we used to call "metal flake". Check the back of the gas filler door.

-

Weber 42 DCOE 8

How about oil instead of fuel? A bad valve seal or oil scraper ring maybe. Are the DCOE's easy to swap? Swap it and see if the problem stays with the barrel.

-

New owner

This site says that "Black Pearl" is paint, stripes, an extra mirror, and a louver. So, look for holes or witness marks where the mirror and louver was installed. https://classiccars.com/listings/view/910782/1978-datsun-280z-"black-pearl"-for-sale-in-beverly-massachusetts-01915 Here's a picture that seems to show the bottom brackets for the louver.

-

New owner

Never mind, I'm wrong. I think that "Black Pearl" is an urban legend, isn't it? Or some sort of ad copy that got blown up in to a thing.

-

5 Speed Transmission inspection and possible rebuild.

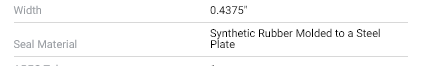

p.s. if you can find the number on that bearing you might be able to look it up to see what, exactly, it is. I'm sure it's fine, but just curious. The number's probably engraved on the side of the outer race. Here's a link to browse the different types of bearings. There's a bunch for all kinds of different applications. Looks like Dave and Chas were right, best to have good lubricant flow through yours. It's not what I thought it was. https://www.vxb.com/Sealed-Ball-Bearing-s/198.htm?searching=Y&sort=13&cat=198&show=15&page=2 2nd edit - and just to fill out the bearing saga, a page showing a "rubber molded to a steel plate" seal https://www.grainger.com/product/35JC49?gclid=EAIaIQobChMIkqvpqK_S6QIVUtbACh2EvQbAEAQYASABEgK_dPD_BwE&cm_mmc=PPC:+Google+PLA&ef_id=EAIaIQobChMIkqvpqK_S6QIVUtbACh2EvQbAEAQYASABEgK_dPD_BwE:G:s&s_kwcid=AL!2966!3!402184946084!!!g!439044420138!

-

5 Speed Transmission inspection and possible rebuild.

Yikes, that's a scary video. I'll bet you were sweating, maybe still are, wondering about pulling it out. But, it's just metal a seal instead of plastic. It looks like it might actually be more of a metal shield to keep crap out. I didn't se any grease, so pulling it will give more lubrication. Can you see the other side? The sealed bearings are sealed on both sides. As Dave said though, the retainer and races hold the bearings in place. The retainer, the metal piece with the bumps in it, is actually also a spacer, keeping the balls separate so that the inner race stays centered and the balls can't get torqued out. Without that piece the balls all end up on one side with a big gap on the other.

-

5 Speed Transmission inspection and possible rebuild.

Underneath the plastic seal is a bearing just like these, from your video, with the retainer wrapped around the balls in the races. You can actually get those exact bearings in a sealed form if you wanted them. Some people use a sealed bearing for the countershaft bearing. Maybe it keeps it quieter. I'm not so sure it's a huge deal, really. There are holes in the adapter plate, at the bottom, I think that allow oil flow. The bearing is loaded with grease before they seal it. But if you peel the seal out you won't hurt anything.

-

5 Speed Transmission inspection and possible rebuild.

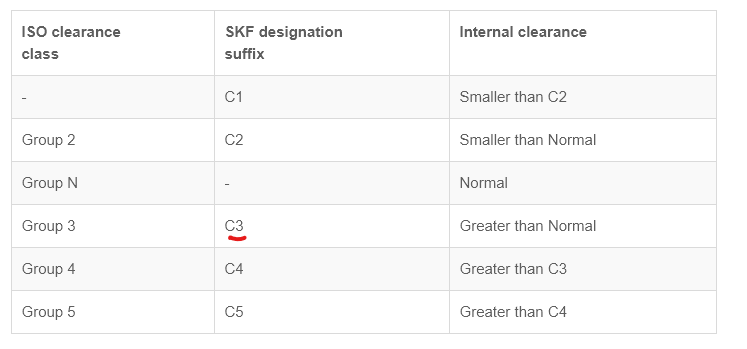

Thanks Chas. Yes, I chose the wrong word. Lazy on my part. But, the SKF guide says that C3 clearance is greater than normal. So, loose. Who knows, maybe a rebuilder should drop the clearance back to normal, since the internal bearings seem to fail often. Maybe they're too loose. https://www.skf.com/cn/en/products/bearings-units-housings/principles/general-bearing-knowledge/bearing-basics/internal-clearance/index.html

-

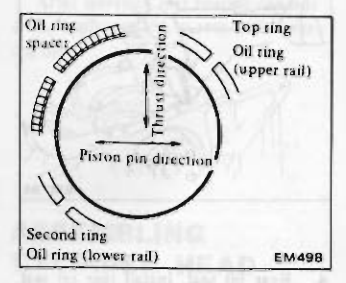

ring gap posistion

I'd guess that the fact they never specified front or back, only thrust direction, means that it doesn't matter. Looks like they're just saying "don't line your gaps up with the thrust direction, make sure top and bottom ring gaps are opposing, and put the spacer gap between the two." They used the same picture all the way through 1983, even with the turbo engine. p.s. I see that I confused the oil ring discussion with the overall ring gap discussion. Sorry about that. Still, it's looking like it doesn't matter much. Space the gaps out and expect them to move during usage. p.s. #2 - it would still be neat to see where the rings are in a high mileage engine. The dynamics might cause them all to end up in a similar position. A "resting" place after their walks.

-

5 Speed Transmission inspection and possible rebuild.

Is there grease inside? Supposedly they are filled with super duper grease designed specifically for the bearing. The purpose is to keep them lubricated when they are used in areas that can't be reached for regular maintenance. The bearings are C3 tolerance which is loose, to allow crud to slip out, as I understand things. but, this reference says it's to allow expansion. Trivia... https://www.bearing-king.co.uk/article/why-are-your-bearings-c3 More stuff. I'm learning. https://www.skf.com/cn/en/products/bearings-units-housings/principles/general-bearing-knowledge/bearing-basics/internal-clearance/index.html

-

5 Speed Transmission inspection and possible rebuild.

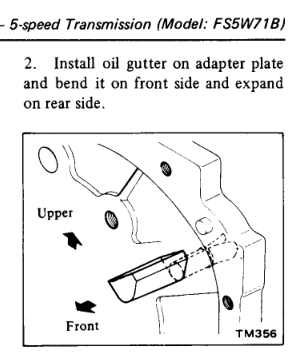

grannkyknot has also rebuilt a 5 speed. EuroDat posted some pictures in his thread. I opened up the 1982 FSM and found a similar issue where they don't show it in the diagram but do describe it in the reassembly text. It's an odd little chunk of folded stamped metal. You could probably make your own pretty easily. I don't think that there's much engineering in it.

-

ring gap posistion

My thoroughness is letting my coffee get cold... https://fpsdistribution.com/articles/piston-ring-gaps-preventing-engine-damage/ " Aligning Ring Gaps Unless pegged, all piston rings slowly rotate round in their grooves while the engine is running. For this reason, it isn’t important to make sure the ring gaps are aligned – though you may find it easier for fitting if you stagger the ring gaps before you apply a ring clamp. However, no harm will be done if the gaps temporarily align in service.

-

ring gap posistion

My point was about what happens, not what was designed to happen. Many two-stroke engine pistons have a peg in the groove and the ring ends are shaped to fit the peg. that's a design meant not to walk. http://m.2strokeengine.net/gordonjennings/twostroketunershandbook.php

-

ring gap posistion

It would be interesting to see where they are on an engine being disassembled. I think that they "walk" over time anyway. I thought that the starting offset was more just to improve the odds of not grooving a cylinder wall or getting poor sealing. I don't know though.

-

1/71 #18720 a.k.a. Sakura

That's pretty high up there in RPM. Curious about the hp/tq? Usually they're reported separately. Which is which? And where/when? The curves would be nice to see.

-

Safety announcement: Check your steering mechanism’s safety, especially if a little sloppy.

So did the clamping bolt fall out and the shaft was working its way free? Sorry, I like to know the answer first then back fill with the details. Edit - so I watched the third video and see that it was loose with the bolt in. I didn't see the fix though. I think that you could probably push your steering wheel in to get more bite on the clamp. It probably has a gap up there somewhere inthe cabin. I have vague memories of realizing that the shaft and wheel could be pulled in to the cabin once the coupler was detached. From when I replaced the the coupler with a urethane unit. I think that that is how I made space to get the old one out and the new one in. It might be a wrong memory though.

-

Safety announcement: Check your steering mechanism’s safety, especially if a little sloppy.

Just an experiment. Copy and paste. Let's see if it worked. Last edited: Today at 3:49 PM AliK, Today at 3:32 PM #1

-

Valve train noise / lash pad question

Here's a couple. I think that Motorsport might be showing more than they actually have. https://www.thezstore.com/page/TZS/PROD/10-2041A https://zcardepot.com/products/lash-pad-cap-valve-rocker-arm-guide-oem?_pos=1&_sid=2e26d0517&_ss=r

-

Tachometer Swap : 280z into a 240z series 1 housing

How did you know that you needed the 8920, and how did you wire it up? Many people can't get the 280Z tach to work with the 6AL even with the 8920. Give some wiring data and you'll be adding to the thread's usefulness.