Everything posted by Zed Head

-

engine removal

Pretty common to lift, move the car, drop the parts and move them, then move the car back. Easier than trying to roll a cherry picker around on its tiny wheels with 500 pounds swinging from it.

-

engine removal

Room for storage or room for maneuvering? There is nothing to hold the transmission up if it's disconnected from the engine. You'll have to rig up some cables or rope and hang it from the hood latch or let it sit on the ground underneath the car, or on blocks under the car. If you want to work on it you'll have to raise the car high enough to slide it out. Those are some reasons that it's actually easier to pull both at once. If you pull both, you can always slide half of the trans back under the car for storage, or stick the starter bolts back in and stand it on end. Takes up about half the space. The bolts are to keep the input shaft off of the ground.

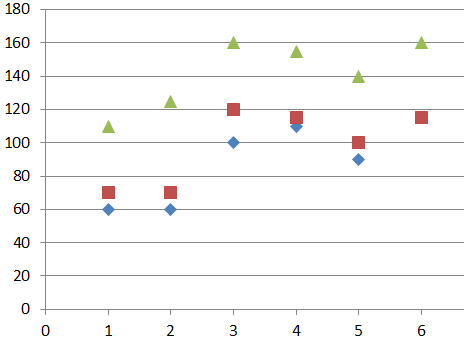

- Sending unit outputs

- Sending unit outputs

- Sending unit outputs

-

240z cranks but won’t start

Whatever you end up doing be sure that the front edge of the rotor is pointing at whichever wire you choose to be number 1. If you understand how the parts work you can make it do what it's supposed to do. The "star" wheel spins, when the two points align spark happens, whichever wire terminal is closest to the leading edge of the rotor gets the spark. Set your damper mark at about 10 degrees advanced, and move the distributor wires and distributor body appropriately so that #1 is where you want it to be. Even if you decide to realign the drive spindle you'll still need to know these things. Trying to look at all of the pieces separately doesn't work well.

-

240z cranks but won’t start

I was just giving too much detail. When the two spikes pass each other is when spark will happen. Based on where the spikes are your ignition timing is retarded. Marked up the picture, below. I think that it might start if you advance your ignition timing. Loosen the adjustment screw at the base of the distributor and rotate the distributor body slightly clockwise while you're trying to start it. You can do it with everything assembled you don't need to see the internals. It's actually pretty common to have to move the distributor back and forth to find the spot that will start the engine, after reassembling everything. Then use your timing light for the final setting.

-

240z cranks but won’t start

Have you tried rotating the distributor to a new spot? Your picture of the distributor shows the trigger wheel in a position that will give retarded ignition timing. If the timing mark is on zero then it's going to be very retarded for starting and running. Turn the distributor body clockwise and that should advance your timing. By the time the damper mark is on zero the spike on the star should have already passed the spike on ring.

-

240z cranks but won’t start

Things look about right. How about valve lash? Any chance it's too tight and you have valves hanging open? You didn't show firing order either, or rotation direction. I've put my wires on backwards before. The engine actually started but it ran like the wires were on backward.

-

Idle dying when warm

Agree. The whole engine really needs a good checking. Obviously it's got problems. If there's one there might be others. Best start with the basics and run through the list.

-

Injector issues....

They're cheap and probably available at one of your local parts stores. I searched on 280Z but 280ZX is the same. The small ring seals, the big top ring applies the downward force and vibration damping. https://www.oreillyauto.com/detail/b/standard-intermotor-5820/fuel---emissions-16775/fuel-injection-16471/fuel-injector-seal-o-ring-kit-12312/ee721b9bfdb5/standard-intermotor-fuel-injector-seal-kit/sk4/6017490/1976/nissan/280z?q=injector+seals&pos=3 https://www.oreillyauto.com/search/1976/nissan/280z?q=injector+seals

-

Idle dying when warm

His first set of measurements seem to show some increase on the second one, but not near the difference between cylinders. Are we over-hoping?

-

Legitimacy of AFR gauges

I don't. That's what I was going to do. Then realized it didn't matter for my plans. I only have to pass emissions every two years and my engine is unmodified.

-

Legitimacy of AFR gauges

I thought about building my own system and just using a look-up table, a real paper one, to mark up a voltmeter. Not sure where "legitimacy" comes in to the conversation. It's just a number from a sensor, some basic scientific principles, and some math.

-

Idle dying when warm

Sounds like the numbers are coming up as engine RPM increases. That might explain why it runs well, with bad cylinder pressures. You probably have lots of blowby. If you have all of the plugs out and the throttle open and a fully charged battery for the most recent test, the only way you could get a little more RPM to bump the numbers up even more might be to connect jumper cables from a running car, to get 14 volts to the starter, instead of 12.6. But it all seems moot, cylinders 1 and 2 aren't sealing well for some reason. Also helps explain why it "likes" a higher idle speed. You might put it all back together and give it a good "Italian tuneup". Go beat the heck out of it on the road. Then see if the numbers get better. Overall though, it looks like you're in the situation I was in when I got my car. An old worn engine that runs okay but could be better. You might have to live with its flaws until you decide to rebuild or swap a new engine in. On the remote starter, just remember that all you're doing is supplying the small terminal on the solenoid with battery power. Power to the solenoid small terminal is all you need. One wire will do it. My remote starter is a piece of wire with a female terminal on one end, to connect to the solenoid, and a bare end to touch to the battery positive on the other. It's kind of sparky.

-

240z Front Control Arm Bolt

Just went and looked at my 76 and it doesn't have any washers at all. I think it's a crimped lock nut also. Nyloc didn't come around til later. Interesting topic. https://data.epo.org/publication-server/rest/v1.0/publication-dates/19820310/patents/EP0047061NWA1/document.html

-

240z Front Control Arm Bolt

You only really need one, since only the nut spins when you're tightening. I don't think there is a washer under the bolt head. The parts guys aren't even supplying the other washer. https://zcardepot.com/collections/front-suspension/products/front-lower-control-arm-bolt-240z-260z-280z https://zcarsource.com/bolt-kit-front-control-arm-240z-260z-280z-70-78-new

- Picking a glove box lock?

- Picking a glove box lock?

-

240z Front Control Arm Bolt

Not sure exactly what you're looking at but it might be shown here. http://www.carpartsmanual.com/datsuns30/Datsun-Z-Index/Axle/Front-Suspension

-

280Z High Beam Switch Repair

I have the whole combination switch from a 1978. Kind of worn, I had to dose it with DeOxit to get the dimmer to work, and also took the HL switch apart to clean it up. It all worked when I put it in the box, and put the box on the shelf.

-

Ghosn Arrested in Japan and Fired by Nissan

Shocking. A rich person avoiding taxes! I can't be party to this, I'm selling my 42 year old old beat up 280Z!

-

Rust Advice 78 280z

Man, I don't know what this means, as a whole or in parts. Only "lazy suckers do their own work, and doing so is a gamble"? Are you recommending that he has somebody else do the work? Or that he buy new parts? Or that he does the work himself? You told an anecdote about doing the work yourself, yourself. Were you saying that you made a mistake in trusting yourself, or that you only trust your own work? Not kidding. I like to leave a little puzzle behind myself sometimes, but I can't tell what your message is. My message was - leave the insides of the injectors alone they've been fine all this time.

-

Rough idle when cold - Running rich

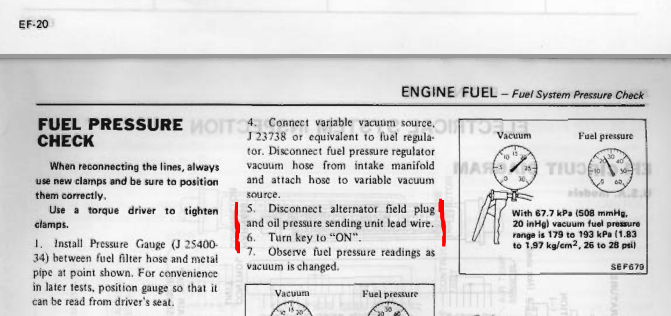

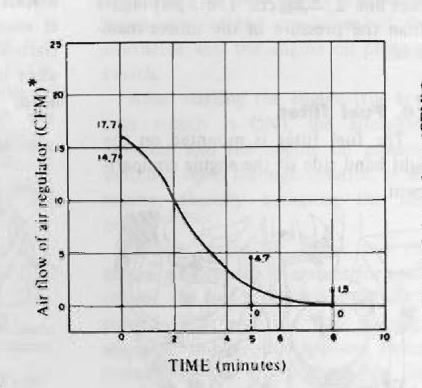

My "adjustment" was just putting a broken one back to where it had been. They're not supposed to twist. Whatever parts you're moving, if it's open at 68 F (not freezer temperature), and closes after about 5 minutes of 12 volts, it's good. I forgot to copy Nissan's chart in before. EF-18.

-

Rough idle when cold - Running rich

I overlooked the fact that you have a 1978. They don't have the second pickup coil. Have you confirmed that the hoses are actually open? So that air can flow through the AAR. It should stay partially open for about 5 minutes. My vague memory of adjusting an AAR is that the plastic terminal end would twist. Maybe I'll go dig one up to verify. But as I recall, I twisted the connector end until the opening was open the proper amount and it also fully closed after battery voltage was applied. Then I glued the connector, which is actually connected to the heater mechanism, to the metal body. I think that they can come loose, as Blue showed in his Tech Tip. Grab the end of yours and see if it twists. http://www.atlanticz.ca/zclub/techtips/aar/index.html