Zed Head

Free Member

-

Joined

-

Last visited

-

Currently

Viewing Topic: It only works if I spray gas into the air intake.

Everything posted by Zed Head

-

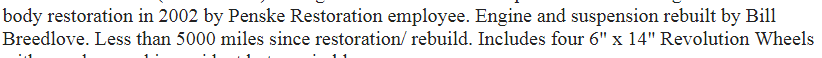

It's up for sale again!

Nobody's going to complain about putting a V8 in that car... Can you desecrate the desecrated? Sorry, feeling poetic.

-

she falls on her face at 3500-4000 rpm

This post says about the same as your first post. Revs freely but has no power above 4000 RPM. Don't really see a difference. The tachometer needle is a good clue for spark problems. It's a spark monitor and counter. Might add some detail to "made it worse". The condenser in the distributor is there to give a stronger spark and stop the points from burning.

-

7" brake booster repair and restoration

Interesting thread on a generally similar topic. Pretty sure we've discussed it over here before too. http://forums.hybridz.org/topic/35455-brake-boostermaster-cylinder-options-on-a-73-240z/?page=2&tab=comments#comment-1206765

-

It's up for sale again!

-

Failed smog test

What is the state of the engine at this point? When did it last have a tune-up, including valve lash adjustment? Last oil change? Did you just buy it? How often was/is it driven? The paperwork says "Fail" on ignition timing. What's that about and what is initial timing? Does the vacuum advance work? Lots of possibilities. Need more info than needs an extra push on the gas when shifting gears. A lot more.

-

New L28 rebuild, the no oil pressure routine

If there's oil to the cam, even a dribble, you're probably fine. The pump is working. And you showed that it would pump a lot at higher RPM with your drill motor test. Once the engine starts you'll be at drill motor oil-squirting speed. People have your problem often, there are very similar threads out there.

-

New L28 rebuild, the no oil pressure routine

Not super clear that you mean the dash gauge or something else. Could use more detail than "nothing". Not clear what nothing means. Do you mean no reading at the dash gauge or no oil through the cam holes? Or something (nothing) else? But the sender and gauge are notorious for reading low and responding slowly. You could disable the ignition system (pull the coil positive wire) and spin the engine with valve cover off to be sure that the oil pump drive gear is working. Spin the engine with the starter and watch the cam holes. I've done that on my garage engines, with a ZX reduction starter, which is slow. It works, oil oozes out at starter speed. You could also get a mechanical gauge and mount it in the sender port, to get a faster reaction.

-

78 280z Severe Driving Problems

I think that CO is referring to part of the original problem, the reason for parking it, above. I saw the same conflict. The question might be what "rough driving" means. It's a dilemma because it might have just needed a good tuneup, if it was running well before. The OP was pondering buying a new AFM, after "calibrating" the existing one. So the $5 AFM tweak would be a good diagnostic tool. It might not solve the popping problem, but if it doesn't a new AFM probably won't either. The basics need to be covered first though, like fuel pressure. Get it driveable, then worry about gas smell, seems reasonable. A non-drivable car with clean exhaust isn't very valuable. There are other ways to get backfiring, like cross-firing plug wires.

-

Slalom grind cam

"Slalom" might be another word for autocross. Or vice versa. You'll need to find some ID marks on it to know for sure but I'd imagine a slalom grind would have lots of mid-range torque and a smooth power profile across a wide RPM range. For high-quality throttle response and steady power application. Not a high RPM, high power, screamer cam profile. There is usually a mark on the back of the shaft, stamped or scribed.

-

78 280z Severe Driving Problems

The engines are very sensitive to even small vacuum leaks. Removing the PCV hose is a huge one and lets umetered air in. The engine leans out when that happens. The vacuum gauge might find large leaks. One test for vacuum leaks that I use is to run the idle speed screw all the way down. The engine should die from lack of air. If it doesn't there's a vacuum leak. If it does, any leaks are probably very small. Good luck.

-

Should buff out

-

Should buff out

-

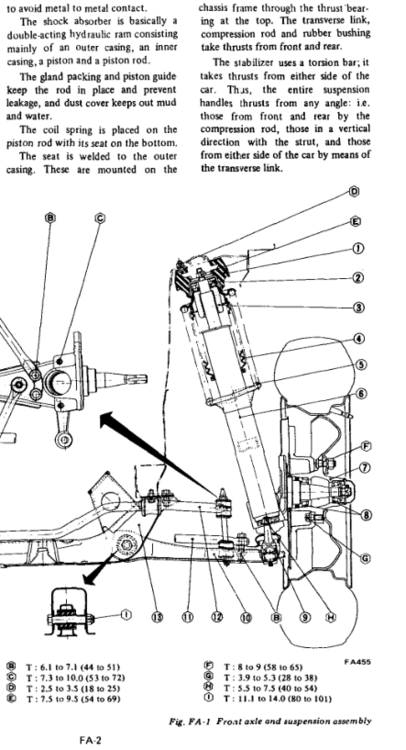

Shop says they can't perform an alignment

There are punch marks. It's described in the Steering chapter.

-

78 280z Severe Driving Problems

All I can do is repeat the above. I don't think you can get back to "zero" without going back to 1978 and using 1978 fuel formulations with a new 1978 AFM. One without 40 years of age. I bought a new MSA AFM and it does run richer than any of the old AFM's I tried. So, that might be a "back to zero" option, if you want to spend the money. But the AFM tweak will tell you more about if it's going to work. Think of the AFM tweak as a diagnostic tool. Adjusting your AFM would be considered a band-aid by many members. It was glued to where the factory set it, wasn't it? Did you break the glue blobs? You can get your fuel pressure by just running the fuel pump without the engine running. Generally, though, your popping symptoms are signs of a lean mixture. So fuel pressure, AFM, and vacuum leaks are where you want to look. Good luck.

-

78 280z Severe Driving Problems

Wow, that is some diagnostic work. Did you mark the starting points on your AFM "calibration". I love the atlanticz site but some of the things on there are not actual factory procedures, but things extrapolated from educated guesses. The calibration procedure was developed by examining a "known good" AFM and assuming that all AFM's should be like that one. It might not be right. I don't see fuel pressure readings although you do have a gauge. Your symptoms, the popping through the AFM, have been solved by many of us by adding the "AFM tweak", or potentiometer, to the coolant temperature sensor circuit. It's described n the atlanticz site also. I would set your AFM back to the starting point and try the potentiometer. Something about today's fuel or a general degradation of the AFM circuitry causes much popping and backfiring with 280Z's. Welcome to the forum. I see that siteunseen has replied, He mighht be suggesting the smae.

-

Checking Sensors

It's on page EF-53 of the 1976 FSM. Probably close in the others.

-

Should buff out

That's why we have the big bumpers.

-

Broken Window Roller - Repairable?

Light spring steel sounds right. I replaced my broken pieces with a used one. But I think I've seen NOS parts out on the interweb. Maybe some place like ZCarDepot even.

-

front suspension and tire clearance problem

Put the shock in and see how it all fits with the gland nut clamped down. You might have been able to make one small cut and had it all correct once it was clamped together. Didn't realize you were going with big cuts like that. You're kind of at the point where only your opinion matters. If somebody can point out a safety issue they should, otherwise it's aesthetics. A thought popped in to my head before - if the part was easily replaceable, this conversation probably wouldn't be happening. But I'll bet your car could be down quite a while if you wait for a front strut to show up somewhere. Beside the cost. Good luck.

-

front suspension and tire clearance problem

It's just the outer case of a shock absorber. The loads are small, relatively speaking. The rest of the parts take up the extreme loads. We are in the "what to do about it" part. If you can make a case for how it might fail after a fix attempt that would be informative. I think it will be about like it was before after bending back, probably stiffer. Barring another curb shot, it will be fine.

-

front suspension and tire clearance problem

You... Are... Missing... The... Point... CO Really surprising since you're the guy that likes to fix broken things. Replacing things without understanding how they work makes me cringe. If you understand it and you can make it do what it's supposed to do, then fixing it is fine. Replacing without understanding is kind of lazy, if you have the time to learn. Surprised at your comment, and the way you made it. It has the period!, game-set-match! tone. Eewww...

-

front suspension and tire clearance problem

A wooden wedge here, perhaps with a circular cutout to avoid kinking the tube, might push it outward. Put the flat base back on your brick and pound the wedge in. Looks like about 2x4 size.

-

front suspension and tire clearance problem

The way that tube is used with today's shock inserts is different from how Nissan designed it to be used. I've had the thought a person could drill that tube pretty severely for weight reduction, because it's role with a shock insert is changed to providing compression on the shock insert. When you have the insert in and the gland nut tight, the assembly is a double wall tube, with the inner wall compressed and the outer wall under tension. If you can figure out where it bent or if the casting is deformed at the base you'd have a better idea of if it can be fixed. Replace it if you can find one but don't rule out fixing what you have. Look at some of the "coilover" setups out there and you'll see that people do all kinds of things to these strut tubes, from no basis in education or experience. And they seem to survive. Not referring to you and Sakura Garage cg, just saying that the problem is not as complex as it seems. It's just a metal tube that needs to be perpendicular to the casting base. The loads it sees are not enormous and the shock insert adds strength. If the straightening effort doesn't work you won't have lost anything.

-

7" brake booster repair and restoration

Looks like fun. I like the big chunks of wood. Looks redneck. Any way to get the forces acting on the outer edges, where the contact points are? Those studs are not meant for that type of twisting force, I think. You could torque/bend those surfaces, or the studs. The clamping points are way out at the perimeter at those dimples.

-

datsunzgarage

Some people have had to either ground or power the other connection because, apparently, its transistor state will "float" (edit 2 - maybe it's not float, just a timing delay) and cause timing problems. It's been written about. So for some it's not a straight wire up and go option. edit - here's one - https://ratsun.net/topic/56630-e12-92-retard-or-no-retard/