Everything posted by Zed Head

-

No spark, where to start?

-

No spark, where to start?

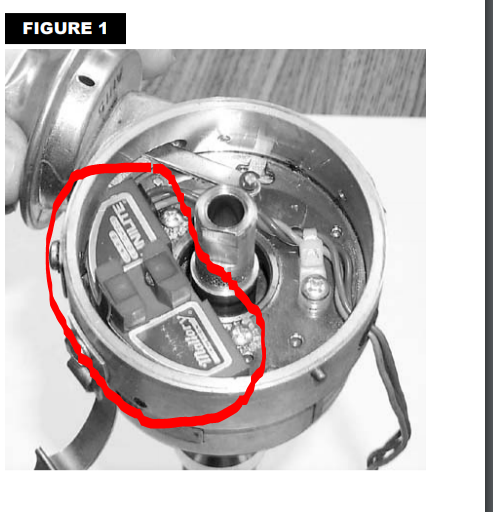

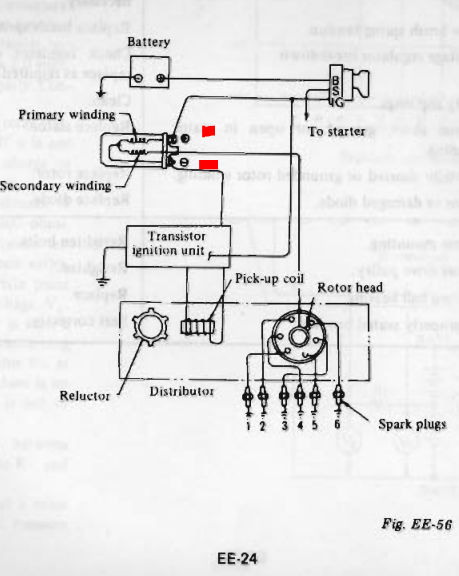

The ignition module is under the distributor cap. The coil would be the cylindrical object with two wires attached, and a center wire that attaches to the distributor cap.

-

Rust Advice 78 280z

Angle of the car plays a factor. Water just flows downhill. You said that you opened the passenger door but didn't say that the water was only under the passenger seat. Anyway, my car had a leaky windshield seal. It leaked in to the channel between the window and the seal from the outside, then flowed to other spots and leaked back out on the inside. I realized what was happening when I saw water beading up at the inside corner of the seal and leaking in when I cornered.

-

1971 HLS30-14938 "Lily" build

See if a shaving will dissolve in MEK. Solvent bonds are very strong. If it does dissolve then you can make your own adhesive from ABS or a similar MEK-soluble plastic. Like site described for repairing a console.

-

OFFICIAL 280Z "Fuel Damper" thread!

Pretty common for that to be caused by the FPR.

-

No spark, where to start?

Edit - plus I think that you're measuring voltage incorrectly for what you're trying to do. But still, there should be no voltage drop unless current is flowing. Voltage should be battery voltage unless current is flowing. There shouldn't be any current flowing unless the engine is running. 3.3 volts implies that your ignition module is shorted out. The bouncing tach needle is another sign. There are some threads on the site about the Unilite modules. You can get replacements. And here is a test procedure for the Unilite. Not exactly your model but they're all the same. http://documents.holley.com/605_v2.pdf

-

240Z Dual Weber 32/36 Carbs: Problems starting when warm

- My Rockers seem to be a little off, or I'm off my Rocker(s)

Third to last post here has pictures of my original 1976 rocker arms. They have the trapezoid. http://forums.hybridz.org/topic/118926-engine-woes-read-on-if-you-dare/?tab=comments#comment-1122036 Here's one.- My Rockers seem to be a little off, or I'm off my Rocker(s)

I started a thread on rocker arms a few years ago over on Hybridz. Haven't clicked through the links again so don't know how many are good. http://forums.hybridz.org/topic/119576-rocker-arms-state-of-the-situation/- My Rockers seem to be a little off, or I'm off my Rocker(s)

I'm just posting for fun so don't get mad. You're still talking about appearance, not function. Big picture, when you do things that don't really need doing you often end up with a whole new set of problems. So, estimate time needed to get the work done then double or triple it, and the cost. You might flatten your cam lobes, for example. Do you want to drive it or have a picture of nice looking parts that you almost never see?- My Rockers seem to be a little off, or I'm off my Rocker(s)

No offense, but this is a classic case of cognitive bias. You're planning to "fix" what looks bad, but isn't measurably bad. The pits might actually hold oil for better lubrication. Anybody ever seen cracked big ends on connecting rods? They look broken. https://www.eeuroparts.com/blog/1939/engine-might-cracked-connecting-rods/- My Rockers seem to be a little off, or I'm off my Rocker(s)

If there are no grooves or low points on the "good" metal then the pits are really just a cosmetic issue. Function versus appearance. You might create a bunch of extra work and future problems by "fixing" the pits. Did you measure lash before removal? It would have increased if you had wear problems. An alternative view.- 280z Starting help

Well then you don't have to worry about the ballast resistor. Turn on the key and measure voltage at the coil. Either terminal will do.- Battery arc'd and shorted, is alternator now toast?

Thought that "don"t run the engine with the bad parts in it" would come through the comments, but, just in case...don't run the engine with the bad parts. Actual voltage is probably higher if you're just reading the highest number on the gauge. You might be damaging more stuff. And the speedometer is mechanical. So any twitchiness there is not from an electrical problem.- Electric Fuel Pump Install

Your 240Z? Where did you get an oil pressure switch?- 280z Starting help

If your last coil really was a dead short then it might have fried your ignition module. Have you confirmed that the coil has power? And tested the pickup coil in the distributor? And that the coil is connected to the ignition module? There's a lost more to testing the ignition system than measuring coil resistance. Did you use a meter or a test light on the coil? Might be that the coil was fine. What year 280Z?- Injector Identification

You'd need to know the fluid they used also. Could be that they were only testing for consistency, like a cylinder pressure test. It's NAPA, not a business specializing in injectors. Don't make something from nothing, unless you're looking for things to do. If they're flowing 100 instead of 188, the car will be undriveable.- 78 280z Severe Driving Problems

- Injector Identification

They're common auto store replacements. The flow rates need to have a pressure associated with them to know what the rates mean. The fact they're all the same and that somebody bought them for your car suggests that they're probably fine. You'll know by how the engine runs if you have problem.- Too Good to Be True? – 125 Amp Bolt in Alternator @ Datsun Store

Pending failure. You could probably get it to work. Zspecialites could have designed his to work.- alternator rebuilding-78 280Z

I have a Bosch reman and it came with a label that said every electrical part was tested and if it met specs it was reused. They're generally poorly reman'ed. Lots of failures soon after buying. An attempt at a rebuild would be interesting. Has yours failed or are you planning ahead?- Tempted on removing, cleaning and reinstalling hitachi original distributor on my 240z

It's not a bad video, it does show how the parts fit. The locking plate on your 240Z will be slightly different but the basics are the same. You don't need to slather on all of that silicone sealant. Just use the gasket.- 2+2 gets some SEMA love

From what I remember the car never sold. It was on eBay but they ended the sale. I think they thought it was worth $80,000. Then it was on the Gas Monkey site as For Sale but nothing happened if you clicked. Maybe they burned it for the show.- 78 280z Severe Driving Problems

His video in Post #26 kind of sums it up, it's not really drivable. And in some of the others, #74 for example, he reports 42 psi with just the pump running, his injector flow test. Several odd things going on. Still haven't confirmed that the gauge is good. Several simple things could be knocked out to make the overall situation more clear.- 78 280z Severe Driving Problems

- My Rockers seem to be a little off, or I'm off my Rocker(s)

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.