Everything posted by Zed Head

-

gas tank vent line question

You're the guy with the V8 car over on Hybridz, right? No biggy, just saw the name. Is the tank still there? The system should be leak-free everywhere, in all of the lines. In operation, sometimes it sees slight pressure, sometimes it sees slight vacuum. There's a releive vlave in the gas cap and a check valve in the vent line to the charcoal canister. Wouldn't be a surprise if your charcoal canister is gone also.

-

Engine test stand

Have you given it some wide open time? Get the fuel flowing through those old crusty injectors, with the pintles banging open and shut. Probably help clean up the plugs too.

-

Replacing S30 Rear Wheel Bearings

True. A lathe might be the way to do it. Set it up so that one journal is centered and the other should be too. Maybe a flat surface with the axle journals on it and a bright light under the contact points, or some very fine feeler gauges. But the dilemma here is the axles could be fine, but the seating of the inner race is not. Just looking for confirmation. Since he has new bearings coming, he might as well pull the ones he has and reseat them. Maybe swap bearings on the axles in question and see if the problem follows the axle or the bearing, or neither. Maybe one of the bearings has a bent ball retainer, for example. Once the two races get aligned the retainer locks up? Or the inner race itself is defective. Could be cracked. Just guessing. A bearing swap might tell something.

-

Calling all engineers

Just remember that the period of oscillation is independent of the mass of the pendulum. Ha ha ha... Wikipedia. I don't know any of this. And don't feel bad, Galileo had problems too. Maybe you should pray. https://en.wikipedia.org/wiki/Equations_of_motion "Galileo did not fully grasp the third law of motion, the law of the equality of action and reaction, though he corrected some errors of Aristotle. With Stevin and others Galileo also wrote on statics. He formulated the principle of the parallelogram of forces, but he did not fully recognize its scope. Galileo also was interested by the laws of the pendulum, his first observations of which were as a young man. In 1583, while he was praying in the cathedral at Pisa, his attention was arrested by the motion of the great lamp lighted and left swinging, referencing his own pulse for time keeping. To him the period appeared the same, even after the motion had greatly diminished, discovering the isochronism of the pendulum. More careful experiments carried out by him later, and described in his Discourses, revealed the period of oscillation varies with the square root of length but is independent of the mass the pendulum."

-

Replacing S30 Rear Wheel Bearings

Do you have any way to measure runout? Should be there. Sounds like you removed the shaft and the installed bearing. Could be a damaged bearing. There's also tolerancing. If T3's bores are on the small side and you got a "big" bearing race, maybe it's still a fit issue. Sounds like you'll get it fixed, just not clear, exactly, what the problem is.

-

Oil filter adapter removal

Sometimes the CZCC site will take a pasted link and sometimes it won't. It's not consistent. Looks like it didn't this time. Have to click the little chain link, then paste, then save. Here it is after a bunch of extra effort - https://www.courtesyparts.com/oem-parts/nissan-oil-filter-stud-15213w040a

-

Oil filter adapter removal

If you Google the part number you'll probably find a few sellers. Your local Nissan dealer might get it for you with free shipping.

-

I've been looking for a project

Are you on lick washers or torque specs? http://www.carpartsmanual.com/datsun/Z-1969-1978/brake/front-brake Torque specs are at the end of the Brake chapter. Service Data and Specifications. Forgot to say, CZCC has the FSM's on the site now. https://www.classiczcars.com/files/

-

Oil filter adapter removal

Pretty sure you need #14. Looks like they're still out there. http://www.carpartsmanual.com/datsun/Z-1969-1978/engine-280z/cylinder-block/14 https://www.courtesyparts.com/oem-parts/nissan-oil-filter-stud-15213w040a

-

Picking up a 1977 280z 6 Hours Away. Tips?

O-rings are interesting things. They were developed to replace old fiber and grease packing materials. They are supposed to have a fairly precisely sized channel to live in to work correctly. Not really meant to be squished flat. I think that I just used some Hylomar blue non-hardening sealant on mine. You could make your own paper gasket pretty easily. Lots of flat to worth with.

-

sheared water pump bolts

Don't overlook the original impact tool - a heavy hammer and a strong box end wrench.

-

Picking up a 1977 280z 6 Hours Away. Tips?

I'm not so sure that there's an O-ring there. The ones I've seen are just two machined flats, no gasket, no O-ring. Worth removing to take a look, for sure, though. Easy. 19 mm wrench. I just went and messed with one I had off to see what I remembered. The body of the one I looked at is metal, crimped around a plastic mechanism. some have a metal plunger. I don't know if there's an O-ring inside or not. But the plastic portion was loose in its seat in the metal body. I wiggled it and oil started to work its way out. I think that the plastic, or internal O-rings, shrink after a few million heat cycles and leaks start.

-

Replacing S30 Rear Wheel Bearings

So it's just a boring and honing operation, probably. Should have left the final sizing for after it was all welded together. You might see some scrape marks in the bore, showing where the fitment problems are. A bright light and a camera could help.

-

KONI Sports for Classic Z's

Thanks for the clear reply KONI Lee. You covered all of the bases. Since the factory struts were designed to be sealed and full of fluid, maybe, for the guys that like to go the extra step, cleaning, priming and painting the inside of the tube would be worthwhile when converting to replaceable cartridges. Rustproofing via coating, instead of oil. Oil is kind of messy and can slosh up and cause a grimy strut tube top. Sometimes people think that their strut is blown when it's just had a cartridge swapped for the old internals. Just adding a little more to think about. The old Nissan fishy-smelling oil is what typically ends up back in there.

-

1976 280z engine runs rough then dies, will not idle.

mbz, you're not getting the internet. Like you've just found it. You had a misunderstanding. Go ahead and put your "Haterade" cartoon back up. I left the thread on a calm note, you have the stir stick. Carry on. It's good entertainment. Edit - just realized something. It's not "your thread". We all share here. It's everybody's thread.

-

Replacing S30 Rear Wheel Bearings

Do you have any closeup pictures of the bearing mounting area? It would be interesting see. That's a fairly complex area to fabricate to those tolerances, from scratch. Matching two bores in concentricity, parallelality, along with dimensions. I made the second word up myself. I didn't know anybody was trying to match the Nissan product there. That would take some skills.

-

Wheel cylinder too tight on plate, won't slide?

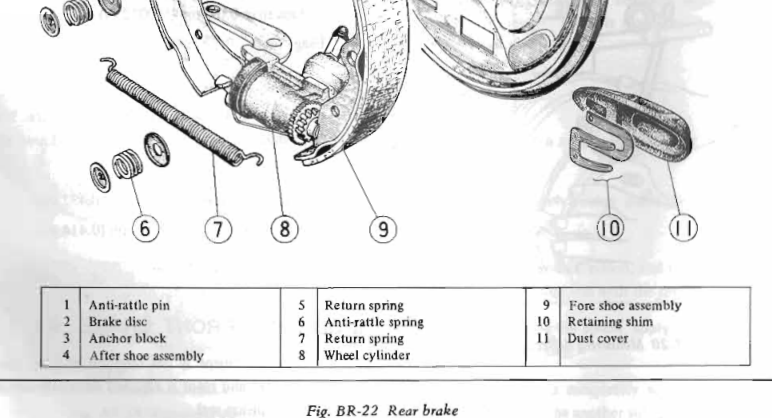

Are the retaining shims in good shape and installed correctly with the dimples matching? They have a certain curvature to them too, the bow of the curve is the contact point. You can see it in their drawing. You can get them on backward.

-

1976 280z engine runs rough then dies, will not idle.

Thanks Patcon. I was just pointing out that the answer to the problem was there over a month ago. I thought I might get a "haha" back. Maybe the realization was irritating. "Haterade" was off-track, and a mistake. That's the main problem with the internet, it records everything. Easy to go back and see what's what. Anyway, another Z survives...

-

1976 280z engine runs rough then dies, will not idle.

No problem. Last.

-

1976 280z engine runs rough then dies, will not idle.

I shine pretty well in this thread. Your appearance is up to you. I didn't quote you so it's gone once you edit. Your call...

-

1976 280z engine runs rough then dies, will not idle.

At least you're more honest now that your problem is fixed. You were hedging your comments when you needed help. Good luck with it.

-

1976 280z engine runs rough then dies, will not idle.

-

Any good places or auctions to find 240z or 280z?

718Miata did kind of hijack the thread to show off his Mecum car. Maybe davis23 didn't recognize it anymore...

-

Help me somebody...spark knock 123Ignition dizzy. I’m

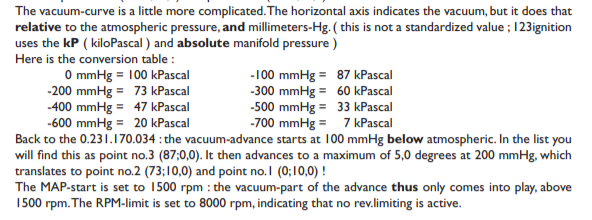

I found the link to the manuals for anyone that wants to browse. The 123USA web site is in bad shape. http://www.123ignition.nl/files/manuals/123manual_TUNE.pdf https://123ignitionusa.com/pages.php?pageid=10

-

Help me somebody...spark knock 123Ignition dizzy. I’m

Yes, MAP is what you would change to get timing to retard at low intake vacuum, when you open the throttle at low RPM. MAP is intake manifold pressure, and centrifugal, or RPM, is engine speed. Two different curves, typically shown in table form. They interact.