Everything posted by Zed Head

-

Rear end suddenly clicking

If it's safe to be under it, with good solid jack stands, just crawl under there and spin the wheels and see if you can locate the noise. You might have to lift the wheels up some by the control arms though because the u-joints will be at an extreme angle with the wheels hanging. Check the flanges on both ends of the halfshafts for loose nut and/or bolts. The noise sounds a little bit like loose parts. Might even be loose lug nuts, better check those too.

-

Rear end suddenly clicking

Are the diff axles firmly seated in the diff? Is the car lowered? Do you see any rub marks? You have u-joint halfshafts, but they usually clunk when shifting if they're loose. You're clicking noise doesn't really sound like a u-joint, but it's not clear how fast you were going when you made the recording. The screws can be removed and a Zerk fitting installed if you want to grease them up. Look for rust around the seals. If you see some the joint is shot.

-

Engine test stand

Sticking advance mechanisms in the distributor? Vacuum or centrifugal. Air gap might be affected by RPM.

-

Engine test stand

If it's rich the potentiometer isn't going to help. So did the weird behavior go away? Did anyone suggest the usual "check your FPR vacuum line for gasoline" test for a failed FPR? You're a newbie now....

-

Picking up a 1977 280z 6 Hours Away. Tips?

The thing about the EFI cars is that have a pretty large filter before the rail already. The prefilter is mostly to save the fuel pump.

-

Picking up a 1977 280z 6 Hours Away. Tips?

I thought the purpose of the filter was so that you wouldn't have to drop the tank? The filter is the peace of mind.

-

Anyone know what this document is?

Interesting that it came with the 5 speed. The lein holder would just be the bank he borrowed the money from, right. Typical car loan. The bottom half is probably the "agreement to pay" with the buyer's signature, that the dealership keeps. Looks like Herbert was a government employee. Maybe military. GEICO insurance before they opened up to the general public.

-

Exhaust/fuel smell in cabin?

Two completely independent posts on the exact same fix. Has to be good!

-

Exhaust/fuel smell in cabin?

That vinyl covered cardboard finishing panel on the inside of the hatch needs to be sealed all around its perimeter. There's a gap around the latch mechanism that lets fumes get sucked in. The area at the back of the car is a high pressure zone compared to the inside of the car. Ironically, the problem gets worse when you open the windows because the air flowing by the windows pull air out, which gets replaced from the back end.

-

Anyone know what this document is?

-

NEW MEMBER - NEW CAR

I thought it was a tow rope coiled up underneath. Looks like it might have tweaked the license plate. The picture of the engine bay shows a stock radiator. Pretty good paint job. They masked off the engine bay instead of just overspraying.

-

NEW MEMBER - NEW CAR

Is that the AC radiator showing underneath? Probably saved your lower fascia from tow rope damage. 25 year old tires are probably bad no matter how much tread is left, be careful. They blow up. These motors all tick.

-

Basic brake bleed on older Z, reservoir-level not dropping

What happens at the bleed screw? Does the pedal go to the floor when you have a front bleed screw open? Or does it stay high like pressure is building? Describe what's happening, in detail. Probably a clue in there. Also, where you started. Why did you decide to rebuild the MC?

-

Replacing S30 Rear Wheel Bearings

Last thought - a bent wheel side flange would measure out as a bent axle, relative to the wheel flange. The bearing seating surface would be off-perpendicular to the axle bearing journals, except for two exact postilions. Seems like the most likely cause. Somebody slid in to a curb in the past maybe.

-

Replacing S30 Rear Wheel Bearings

Being certain before knowing just makes a person less likely to see what's there. Cognitive bias. No offense. If you consider it mechanistically, like what, exactly, is touching and binding, then a race misalignment seems like a good possibility. The bearings have play in them from the start, properly installed, you can lift your wheel up and down a noticeable amount when the back end is lifted. And push-pull it in and out. Seems like there'd have to be quite a bend in the shaft to get a bend-bind. A short distance piece, giving zero end play, and any type of misalignment will be magnified. Might be interesting to measure end play while you're torquing. If it goes to zero before you get it fully torqued, that's a clue. Zero end play would require perfect race alignment for the balls to ride in. It must be ball-bind that's the issue. Ouch. They need room all the way around the track. You might find varying end play as you rotate the flange. It's an odd problem. I've been surprised at how loose the rear bearings are, in general. But that's how most rear wheel bearings are, even in live (solid) axles. I had an old 55 Chevy truck that wore out a bearing completely, spitting the balls out, riding race to race. You could lift the rear wheel up about 2 inches when it was on the jack. And it just kept going until I sold it to a guy who was going to restore it. I was a didn't-care teenager.

-

Replacing S30 Rear Wheel Bearings

I'm leaning towards a seating issue. Four surfaces, any one of which could cause a problem. The inner races and distance piece form a solid tube of steel connecting the flanges together. Might even be possible to take the bad axle and bearing set and use a pipe and a press to be sure that the inner race is fully seated. Pound it down on the wheel flange surface. Then reinstall and see if torquing still causes the problem. Don't really the use of the nut as the final press of bearing installation. It's not "right". Aesthetically displeasing. I haven't done one but if I did I'd try to knock each race in to place separately if I could figure out a way.

-

Swapping to f54/p90

They rust inside the bore of the housing. The threads could be fine but the shaft will be stuck.

-

Replacing S30 Rear Wheel Bearings

The bearing on the wheel side is staying on when you do the swaps right,press fit on the axle journal? So you have either the axle or the bearing as the problem, probably. There's much discussion about damaging races, "brinelling", by pulling on the outer race,if the inner race is pressed on. But during installation, you're pushing backward on the outer race as you tighten the nut and they seem to survive Seems like you could separate the bearing from the axle and test both independently. If you had lots of free time...

-

Replacing S30 Rear Wheel Bearings

Don't forget the other two seating surfaces, besides the distance piece. One on the axle and one on the companion flange. A piece of grit or a metal shaving could have a big impact. Edit - the distortion might not happen until the nut is torqued and the inner race gets cocked.

-

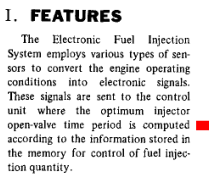

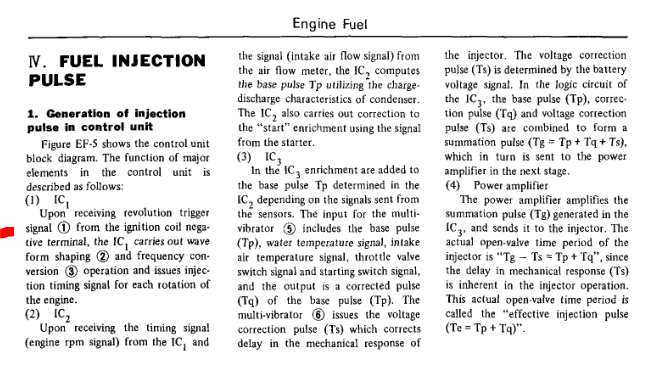

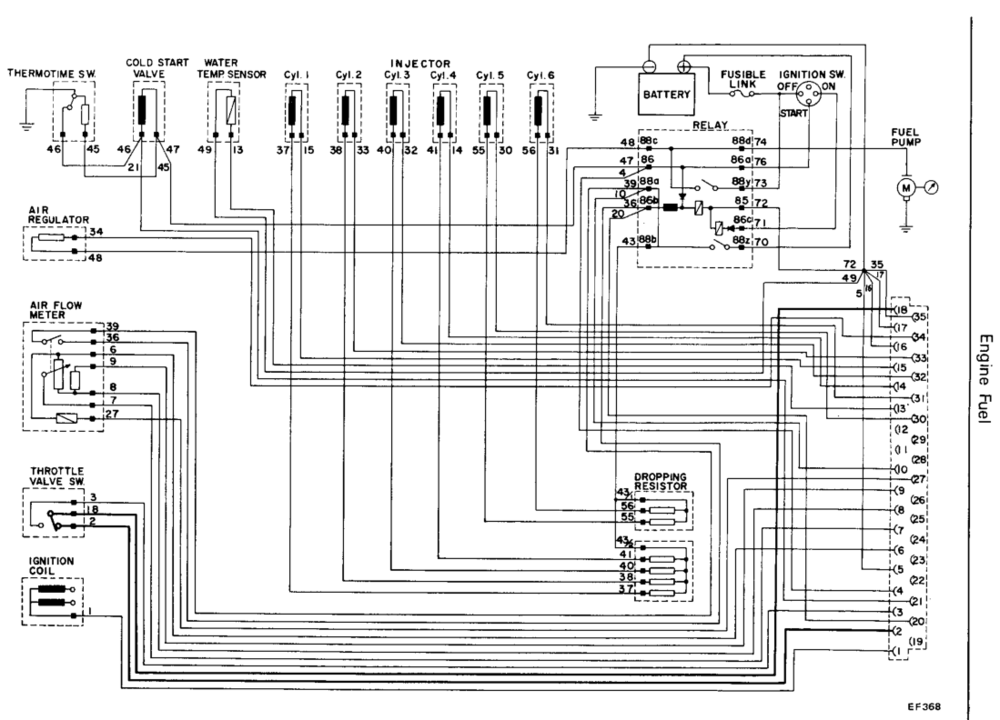

Engine test stand

When my ignition module was going bad it would "over spark", causing the tachometer to read high and the engine to run rich. A possibility. Maybe you have the opposite problem, with a weak ECU trigger pulse. Along the same lines as the tachometer connection issue. Pin 1 "expects" a certain type of "pulse". I don't really know how it works, if it's flyback from the coil discharge or if it's a high and low voltage thing. Do you have all of your wires bundled together? Maybe you have some crosstalk on those signals, or the Pin 1 pulse is getting attenuated. Try splitting them up and checking all connections. Make sure that the ECU has a good ground, maybe the Pin 1 pulse needs that to start the cycle. I know little about electronics.

-

Engine test stand

Not sure how exactly it would explain your problem but if I recall correctly, power is supplied in banks of 2 and 4 and grounded in banks of 3. Although the diagram numbers imply 4 and 2 for grounding also, at least by the wire numbers. Can't remember for sure, CO knows. If the problem is electrical it might follow the plugs. Maybe switch a "fine" one for a rich one and see if it stays or follows. I used the funky looking factory resistor, with the two bullet connectors. I think it's 2.4 kOhms.

-

gas tank vent line question

There are calculators out there. http://blog.cantonracingproducts.com/blog/how_to_estimate_your_engines_fuel_flow

-

Engine test stand

I did something somewhat weird when I had my EFI system hooked up on my garage engine. I connected the blue tach wire through the resistor and to ground. Because in the past I had found that my car would not start with the tach disconnected. I had even had my car not start while I was out tooling around one day when the resistor fell out after I had messed with it. I saw the resistor on my passenger floor board, put it back in and the engine started. Since then, with a GM HEI module in place of the stock ignition module, I've found that it will start with the resistor out. But back when everything was stock t would not. So maybe the stock system is finely tuned to all of the other parts. My garage engine with standalone EFI like yours fired right up as long as I had the idle screw cranked open. Needs that air when it's cold. Anyway, worth a shot, easy to do. Just find that blue coil (-) wire branch and run it through the resistor to ground.

-

75 280Z door seal

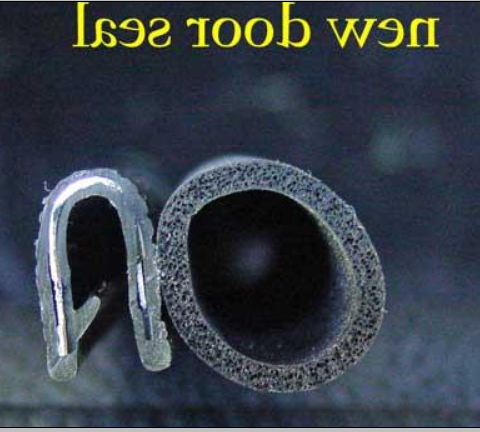

I flipped your picture to match. The Kia Sportage seals work very well. They even have a 90 degree bend for the corner.

-

Replacing S30 Rear Wheel Bearings

Manufacturing companies are always trying to cut costs. It's in their DNA, it's actually part of the deal of being a public company, maximizing shareholder value. Sometimes they go too far. You never know. https://www.nytimes.com/topic/company/timken-company https://www.google.com/search?biw=1496&bih=723&tbm=fin&ei=yRXCXK_sHtnN0PEPhaKo4A0&q=NYSE%3A+TKR+&oq=NYSE%3A+TKR+&gs_l=finance-immersive.3..81i8k1.3013.3013.0.3293.1.1.0.0.0.0.55.55.1.1.0....0...1c.1.64.finance-immersive..0.1.55....0.DgBSm6n_rFc#scso=_zRXCXOziLoK-0PEPw6WEuA82:0