Everything posted by Zed Head

-

Duffy's 1/71 Series 1 240z build

The LSD isn't doing much unless you're turning. No clutches slipping. Might be a clue. Check the simple stuff like lug nuts. They'll make those kinds of noises as the wheel wobbles back and forth. Pretty sure also, that somebody just had a simlar noise and it was the half-shaft flange nuts/bolts at the wheel. Check all of your nuts.

-

Complete Misfire on Three Cylinders

The head gasket/block/head combinations discussion can get convoluted. Especially if you get in to what the high power guys do to their heads to balance the cooling, drilling holes and attaching extra coolant lines. Sometimes people assume that all of the passages available need to be open and flowing as much as possible but if you follow the Nissan design path it looks like they modified the head gasket to control flow, by blocking or reducing the size of certain passages. There was a picture recently that showed it clearly with rust spots on the head gasket where the ports were blocked. So if you're mixing head and block you have some thinking to do. I've always thought that the head gasket should match the head. The head is what warps if cooling is bad, the block is essentially just a reservoir of coolant. And it's not a block gasket, it's a head gasket.

-

Air ducting for 280z

Exactly. I was just adding to the lack of clarity. For amusement.

- Air ducting for 280z

-

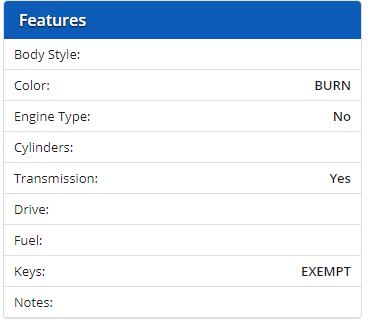

GET AN s-30 ZCAR FOR A STEAL!!!!!!!!!

-

high idle speed issue

The fragments would get splattered up to the valve cover and around up top but once they get to the pan they have to go back through the filter before reaching a bearing. Might be interesting to split the filter open.

-

high idle speed issue

People usually catch it sooner but, yes, that's the typical pattern. The pressure is on the lobe. A picture of the base circle might show a nice untouched surface. Here's an old thread -

-

high idle speed issue

It looks like just wear. Once you break through the surface the lobe can wear quickly. The base circle looks intact, it's on the rocker pad in the picture, which indicates proper valve lash. Fairly common, especially during break-in of a new camshaft. Some of the members here have burned through some cam lobes. @madkaw I think, for one, if I remember right.

-

Trouble shooting

The sporadic nature of your problem suggests those two electronic parts. There's not much to the HEI module wiring, on a 280Z. You can connect it temporarily in the engine bay with some jumper wires and a screw or two.

-

Trouble shooting

I didn't read back through all of the posts but this one and the following kind of suggests either an ignition module going bad, too many sparks causes too much fuel, or an ECU going bad. Tthey tend to go rich first then just die. You mentioned what what the tachometer needle was doing when it was starting to die. You talk about "roaming" and that's a sign of an ignition module dying. Mine showed a jumpy needle, reading high, as it was kicking the bucket. A $25 GM HEI module is a simple quick test, and always good to have around anyway.

-

Ron Tyler (RT) differential mount dimensions

Thanks GN. It was a fun project. I realized afterward that a person could probably bend a single piece of steel to fit the bolt positions on the side of the tunnel, then drill holes for mounting and the the GM mount. No welding, just good bending and 5-6 holes drilled. That Technoversion mount is a pretty nice piece of work. Hard to do it yourself for the same value.

-

Complete Misfire on Three Cylinders

I bought a 280ZX engine and it had bolts instead of studs. They looked factory. Seems like the basic question hasn't been defined. What are you trying to accomplish by changing from the factory setup? If you don't care about the studs getting pulled out why not just use thread locker?

-

"Brand new" 280Z

If you want to get more "forensic" you can consider what happens when the engine runs and/or the car is driven. Road debris will hit the inside of the fender wells, PCV vapors will coat the inside of the manifold, the distributor cap and rotor electrodes will darken and pit, carbon will deposit on the spark plug threads and insulator. There's a bunch of small stuff that should look like new after just 350 miles. You might even find a 43 year old piece of gravel in a tire tread, or, the clincher, a pop-top from a soda or beer can.

-

Thick manifold washers - notched wanted

If you look closely at the yokes, and the contact points, and its shape you can see that the design is kind of self-correcting, or self-leveling. Easiest to see on used parts. There are two sharp contact points with the manifolds and the surface under the nut is round, You probably want to maintain the sharp contact points to avoid putting a bending load on the stud. Polish up the rounded surface and make sure that the stud doesn't contact the inside of the hole. It's a very loose fit, so it can move, I assume. A crude looking thing with some serious ingenuity in it.

-

Ron Tyler (RT) differential mount dimensions

It won't stress the u-joint but it might lead to vibration due to u-joint misalignment. The transmission output shaft and the diff input shaft are supposed to be parallel within a few degrees. Most people don't have problems with it though, apparently it's "close enough".

-

Complete Misfire on Three Cylinders

If you use self-locking nuts they'll probably pull the studs out on the next removal. Nissan did not even use lock washers. Actually, they didn't even use flat washers, where the yoke was used. Stud, yoke, nut was all of it. The mismatched flange thickness is the standard problem with headers. John Coffey suggested cutting flat washers in half and tacking the pieces on to the header flange as a fix. Requires a welder of course, but it was a simple and effective solution. http://www.carpartsmanual.com/datsuns30/Datsun-Z-Index/Engine-280Z/Manifold-Egr/From-Aug-76

-

"Brand new" 280Z

Blowing the loose dirt off with light air pressure should be okay, or brushing.

- L28 4 speed swap 240z

-

"Brand new" 280Z

The old way of telling if an odometer had turned over was to see if the 0's were on the same line. Yours look pretty good. Seems like the more fundamental question might be "were all of the 280Z's delivered from Nissan perfect on arrival". That seems to be the assumption for people critiquing yours. Who knows.

-

"Brand new" 280Z

Can anybody read this? Good data right there. Engine serial number, etc. Build date is on the door jamb tag. Lots of highly suspicious people out here. Nissan made mistakes on these cars, but it looks like it what the guy says it is, to me. Why are the intake manifold bolts orange? OMG, it's been molested...

-

Too much gasket sealer on head gasket?

It might help your thought process to realize that the head "gasket" is actually three gaskets in one. The metal cylinder sealing rings, the copper oil passage sealing rings, and the composite water passage sealing material, that also positions and holds the other two seals together. Consider each one separately.

-

"Brand new" 280Z

I just noticed that it also has the diagonal "Datsun" emblem on the hatch over 280Z. My 1/76 build has the horizontal "Datsun" over the 280Z. The paint code looks like an ink stamp put on either before or after painting. Maybe it's an error and adds value, like a miscoined coin.

-

"Brand new" 280Z

It will still have the usual problems of surface rust in the engine bores and corrosion in the hydraulic system. Both are open to the atmosphere through open valves and vents. Don't try to start it without getting it ready to start, and even if the brakes and clutch work they'll probably fail quickly. Good luck, nice find. You could probably flip it to a museum or collector and use the money to buy a drive-ready car.

-

Complete Misfire on Three Cylinders

If he hasn't put a wrench on at least one to try and remove it, it's all conjecture. There are many grades of SS. Just don't know enough to say either way. Has anyone broken a stud when it's free and clear like these? They break when they're under tension, clamping, but I've never broken one when it was exposed like that. Good luck CO. I can't imagine that you'll leave those monstrosities in there after the work you put in to that valve cover bolt hole. Doing one but not the other doesn't fit inside the same brain. The manifold clamping is much more important than clamping a valve cover down. Hence my zip ties joke. It's been 8 hours, they're probably all out by now...

-

Complete Misfire on Three Cylinders

On the other hand, if they are so weak that they can't take a little torque then they'll probably break in use. The only bolts I've broken are the thermostat housing bolts. I've has studs that were difficult to remove but I was more worried about pulling the aluminum threads out of the head than breaking the stud. Beside that, aren't they too tall to clamp? They don't look fully threaded. Unless they're made from cut pieces of all-thread. Did the PO have a stack of washers under the nut?