Everything posted by HS30-H

- Good Info Fairlady Z432R

-

Good Info Fairlady Z432R

Largely cribbed - almost word for word - from posts on this forum.

-

s30Z, Z-L upholstery details

Yes. 1970 'Deluxe' model S30-D Fairlady Z-L would have had loop carpet sill trim pieces, matching the floor and deck area carpet. In contrast, the 'Standard' model S30-S Fairlady Z would have had 'leather' textured vinyl trim to match the floor and deck mat material.

-

New Historical Z car Timeline

Maybe somebody with more patience and stamina than me, and who presumably - unlike me - got through the whole video, could tell me the answer to the (rhetorical?) question posed by the title of this production? What DID Nissan do that Toyota couldn't?

-

New Historical Z car Timeline

Why do these same rotten ingredients keep getting served up in 'new' dishes time and time again? The video would have it that Katsuji Kawamata somehow came up with the 'Fairlady' name first, and *then* decided it would be a good idea to create a line of cars to use it on. Nonsense. The 'Fair Lady' name was simply pinned on something that was already well underway. Next the presenter tells us that the 'SP311' was "...an all new design by Count Albrecht Goertz". Huh? Goertz had NOTHING to do with the SP/SR range. Nothing. Is this guy getting mixed up with the minimal input that Goertz had on the rear pillar shape of the CSP311 Silvia (which had already been styled by Kazuo Kimura before Goertz got anywhere near it)? I reckon so. The Yamaha YX-30 as the Nissan 2000GT/Yamaha project? Nope. The guy has got the wrong project there. And that Yamaha YX-30 project had input from Goertz? Nope. The YX-30 the genesis of the Toyota 2000GT? Nope. Toyota may well have seen it, but they didn't base anything on it let alone the MF10 2000GT. This whole section is garbage. Then the Katayama lore starts. Of course it had to. Apparently Katayama was "the President of Nissan" at the time (another clue to the lens through which Japanese industrial history is being viewed through here) and - amazingly, seeing as he was simultaneously both an 'outcast' and some kind of refugee saint with product line-up input - the video wants to tell us that Katayama alone had dreamed up the idea that Nissan needed a sporty GT coupe in its line-up. Of course, nobody else back in Japan had even imagined such a thing, let alone taken any notice of the fact that worldwide trends in safety legislation and litigation were pushing against the long tradition of open sports cars. Nope. Garbage again. Painting Katayama as some kind of sole visionary is just short-sighted and misleading. Apparently in 1971 the 'JDM' Fairlady Z got its '240Z' emblems replaced by 'Z' emblems. Nope. He's got that backwards. The original '69 up, non-vented, quarter emblems on the Japanese market variants were 'Z' roundels. In the switch to vented quarters, ALL variants got vented 'Z' roundels. Does the presenter think the early Japanese L20A-engined variants got '240Z' quarter emblems? Roll on a little and we have the usual mix-up of facts surrounding the planning of the S30-series range, with the S20-engined models not mentioned at all in the narration. However, pretty panning shot of a 920 432 there, unless I was by this time hallucinating... I got as far as the presenter talking about the Fairlady 240ZG (he calls it the "Fairlady ZG") as though it was the only Japanese market model with an L24, when in fact in September 1971 Nissan offered three distinct L24-engined S30 variants alongside the already available L20A and S20-engined Z variants. My will to live was fading, but I stuck it out. Who knows, things might improve. So when *is* he going to mention those S20-engined variants? He must have forgotten that the S20 was part of the plan pretty much from the get-go. That'll be it. Katayama apparently not keen though. Oh! HERE is the 432-R (no 432?). Afterthought? Presenter mentions the S20 engine as also being fitted to the KPGC10 Skyline GT-R when that model debuted a good year after the Z. In fact the production S20 engine was designed and engineered to allow fitment in the S30-series Z body (capability for both front and rear sump versions) but debuted in the PGC10 model Skyline of February 1969. I guess we should be grateful for small mercies? Nope. I'm not swallowing any more of this. I need a couple of Alka Seltzer.

-

New Historical Z car Timeline

But packed full of mistakes, misconceptions and misapprehensions. As usual.

-

Z's on BAT and other places collection

Indeed. Bill Reagan (bless his heart) made some pretty silly claims about "World Record" prices which made me think of 'World Series' baseball, and now somebody is defending it as though it is indisputable fact and/or impudent and insolent to question it in any way, shape or form. Strange hill to die on. Texas World Record, maybe?

-

Fitting zg flares on rear- determining flare height

Here's what NOT to do. This car belongs to well-known "Serious Collector" and Bring-A-Trailer star 'Lstepp4re'. The Overfender is mounted too low on the body, and is also 'clocked'. All sorts of wrong:

-

Fitting zg flares on rear- determining flare height

Once you've got the Overfenders mounted in the correct positions, THEN you can see how much it allows you to cut and clearance the rear arch sheetmetal. You can get very close to the Overfender mounting points, and this allows you more clearance than you are ever likely to need. Once you are cutting you might as well go all the way. To sum up, the correct Overfender position dictates where you cut, not the other way around.

-

Fitting zg flares on rear- determining flare height

So you should have the swage line to work to, and the Overfender will pretty much find its own position once you find the reference points. Two of the fixing points (Nissan riveted the Overfenders onto the body, but you might want to use another fixing method) are almost ON the swage line, or are just below it. The Overfender overlaps the swage line at the uppermost peak of its curve. At the ends of the Overfender, the forward-facing end positions just above the dogleg and the rear-facing end drops down way below the bumper. Hopefully this photo will help. It is a genuine HS30-H model Fairlady 240ZG and the mounting position is the factory one. The owner chose to insert some black welting between the Overfender and the body - which the factory never did - but hopefully you can still clearly see the body swage line as it runs along the body, the overlap of the Overfender and the two uppermost fixing points which are your reference for the height of the Overfender on the body:

-

Fitting zg flares on rear- determining flare height

They are probably the most accurate reproductions on the market, so they *should* find their own mounting positions when you get the ends close to where they need to be. The main pitfall is mounting them on the wrong side of the car (seen a few cars like that...) but if you have the correct piece on the correct side of the car it shouldn't be too difficult to get them within a few mm of spot-on. How's the sheetmetal on the car? No bondo/filler? Paint thickness?

-

Fitting zg flares on rear- determining flare height

The factory 'Overfenders' were shaped so that their attachment points were pretty much self-evident. The rears had a little kink in the mating face that matched up with the swage line in the factory metal. Generic copies-of-copies and their derivatives may not have such subtleties.

-

Z's on BAT and other places collection

Strong possibility, to say the least. 😉 Amazing how quickly he has built up a loyal fan club in (what he calls) 'The Z Collector Community'. A lot of people seem to hang on his every word. Maybe they are oblivious to the past shenanigans?

-

Z's on BAT and other places collection

Some nice comments by Volvoamazon. Very apt user name. 😁

-

Red 69 production date car on BAT

I know right? Who judges the judges? I guess they do their best in the circumstances, but... Oh, and you downgraded me. I'm not an HS Standard, I'm an HS Deluxe Grande Nose... 😉

-

Red 69 production date car on BAT

Indeed. One of the people big-upping and sucking up to 'The Guild' (LOL) on the current BAT '69 HLS30U auction owns a car which has a bodyshell made out of at least three different cars welded together, but which - inexplicably - seems to have been given an award at ZCon 2021 Colorado. You've heard of the Rumble In The Jungle, but here's the Con At The Con...

-

Z Proto: The next z reveal

Plenty of Z34-based race cars have been built and used in anger. They even had a Spec Series for them.

-

Part Identification

They are right. European mainland countries including Germany, France, NL, Belgium and Portugal, then UK, Australia, NZ and others still had carburettors on their S30-series Z models through 1978. They had choke knobs.

-

Z Proto: The next z reveal

I was thinking more of the big letter 'Z' in the middle of it... i.e. Not 'Datsun'. My theory is that the designers were probably not looking at '75 and '76 year steering wheels for detail inspiration. Same goes for the quarter emblems. The press and the talking heads are babbling about "the 240Z" references in the styling details, but the new car's quarter emblems seem to me to be referencing the original Japanese market 'Z' quarter emblems.

-

Z Proto: The next z reveal

Not the case. S30-S and S30-D, Fairlady Z and Fairlady Z-L started the ball rolling for the S30-series and the tradition was carried through subsequent generations. The '240Z' name was an afterthought. How about 1969:

-

Z Proto: The next z reveal

In the presentation, Mr Ashwani Gupta (Nissan's 'Chief Operating Officer', no less) repeats the lie that the Z's debut was on 22nd October 1969 at the Pierre Hotel in New York, with the 'Datsun 240Z'. The people writing the scripts for these sock puppets appear to have Googled Zhome.com...

-

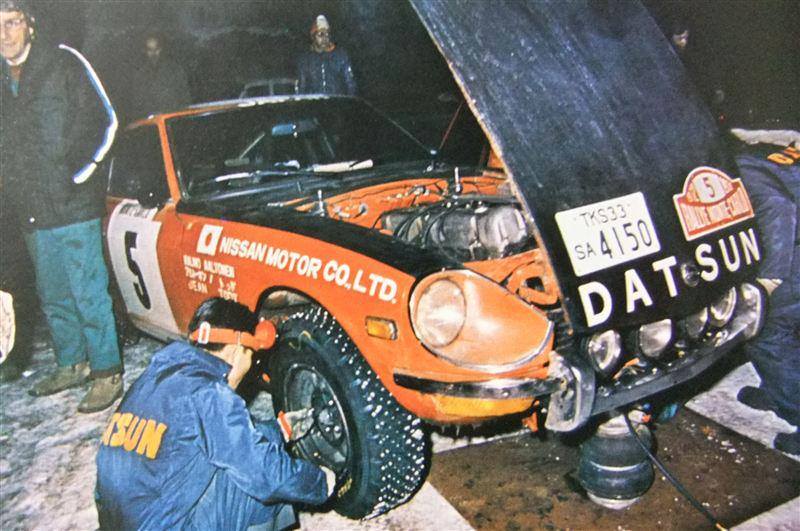

Monte Carlo 240z Front Bumper

Here's a great shot - by pro photographer Dan Redrup - at the same event. Kevin is a past British Historic Rally Championship winner in this car:

-

Monte Carlo 240z Front Bumper

Here's an example of the simplest - non-Works - solution, on my good friend Kevin Bristow's historic 'OMT 868K' car at the Goodwood Festival of Speed Forest Rally Stage back in 2011. The bumper is cut into three and the centre section 'dropped' via the addition of vertical brackets. Fairly easy to do, and this style was used by privateers in period so there's an historic link which satisfies certain regulations when necessary:

-

Monte Carlo 240z Front Bumper

Yes, the way to do it is to cut an original bumper into three pieces and 'drop' the centre section by welding on some flat stock and/or (preferably) finding some nice period over-riders from a suitable sedan and using them as the vertical elements. Yes again. The design allowed the bonnet to pivot open normally on stock hinges, with the front edge swinging over the lamp units. Again, easier to illustrate than to describe:

-

Monte Carlo 240z Front Bumper

Here's an example of a self-built replica 'Drop Bumper' and lights, on one of the VZ Program cars which went to Japan. I've seen the car in person and it is very well done: