Everything posted by zKars

-

FS5W71B Rebuild Thread - Tips tricks and discoveries!

Well there's definitive proof. I will grab my collection of shifters and go try some and see if we can get that sucker in 5th! I have some of those ZX shifters that have the plastic center section with the springs where the pin goes through. There certainly are differences in the pin to end of shifter ball/nylon bushing that sits in the shifter selector rod hole.

-

Electronic Flashers on Sale at Amazon

I'd love to find flashers that have adjustable volume clickers. The combination of a bit of a loud engine, small dim indicators on my Speedhut gauges and advancing age, means I leave my signals on after a non-cancelling low angle turns too often... If I could hear the tick tick tick it would help! Anybody have LED capable flashers with a loud click built in?

-

FS5W71B Rebuild Thread - Tips tricks and discoveries!

Purchase and successful assembly of this https://puralty.com/collections/mechanical-masterpieces/products/marble-coaster should be pre-requisite training for manual transmission rebuilding.

-

FS5W71B Rebuild Thread - Tips tricks and discoveries!

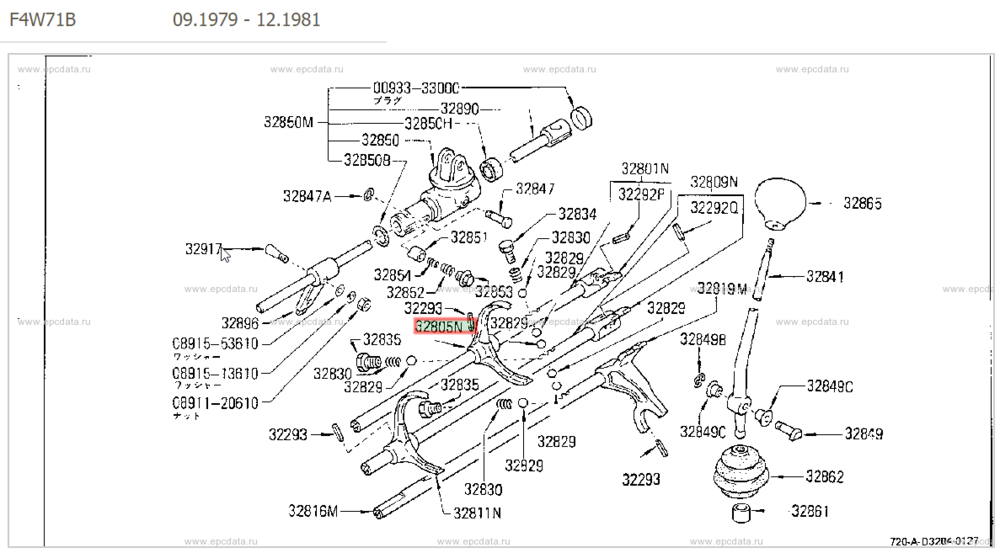

Okay, got a 4 speed opened up. Short answer about the fork interchange 4 vs 5 sp. No. However, the forks are the right "size" for the selector sleeve, and the rods fit through the fork holes correctly, BUT the roll pins are in different locations, both rotational and longitudinally. So you "could" interchange them IF you re-drill the rods for the pins in the right place. Simple right? They aren't hardened or anything, right? BTW the roll pins are smaller OD on the 4 speed. And since the 4 speed forks are steel, you "could" cut the rod part off and "move" it to the right place for the roll pin on the 5sp rod then weld it back on! Short answer no, but in a pinch, you know race day, car broke, final race of the season, if we could just finish the race, we get first overall, then yes, you can make it work..... You know the "C" type trans are more or less the same inside too.... Maybe their forks are backward compatible. You're going to make me take a C type apart, aren't you?

-

FS5W71B Rebuild Thread - Tips tricks and discoveries!

Decent quality parts blow up diagrams for the FS5W71B with the included source URL's where you can go to get detailed part numbers for every little itty bitty piece, as well as a merged in part number listing from EuroDat. trans gear and shift drawing_Land.pdf

-

FS5W71B Rebuild Thread - Tips tricks and discoveries!

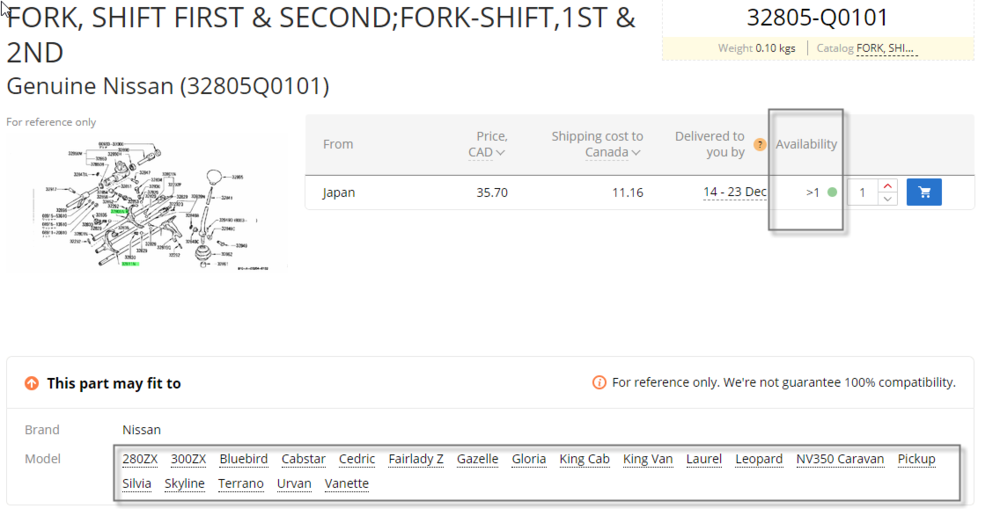

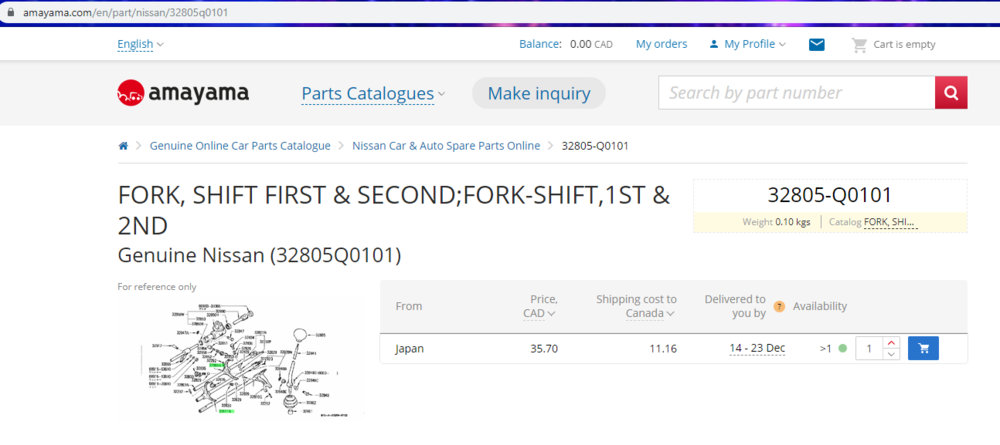

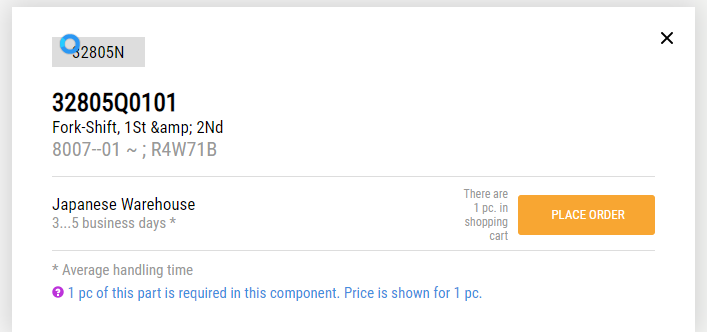

Quick word on parts availability, in this case my badly needed 1-2 shift fork Note the list of other Nissan vehicles at the bottom that have a 32805-Q0101 Also encouraging is the Availability column. Apparently they have more than 1, the other site wasn't quite as encouraging.

-

FS5W71B Rebuild Thread - Tips tricks and discoveries!

Thinking back to some of the 4 speeds I've torn down and scrapped in the past, I seem to remember that the shift forks are steel not aluminum. The 1-2 fork in the five speed also has an extra hole where the 3-4 rod passes through for extra support. I do not remember that extra hole in the 4 speed fork. It may "work" if its exactly the same size, and the roll pin is in the same orientation and position. The 4 speed referenced in my parts search above isn't an FS4W but is R4W71B, so our Z four speeds may be quite bad donors for the Z 5 speeds.

-

FS5W71B Rebuild Thread - Tips tricks and discoveries!

Inquiring minds must know. 4 speed tear down and comparison coming. I have enough. More donors for input shaft clutch alignment tools. Those plastic POS alignment tools that come with clutch kits are, well, not good enough.

-

FS5W71B Rebuild Thread - Tips tricks and discoveries!

I need a 1-2 shift fork for one of the transmissions: That groove on the left edge of the fork is not supposed to be there. It can't push the selector over far enough any more to engage 2nd. Part numbers are: 32805-E9001 or superceded to 32805-Q0101 Two sources in Japan "may" have them in stock: https://www.megazip.net/zapchasti-dlya-avtomobilej/nissan/datsun-2091/720-6047/cg720-616817/shift-control-7732629# or https://www.amayama.com/en/part/nissan/32805q0101 Listings also suggest they share with 4 speed transmissions (R4W71B reference below). As I have a couple of stock 240z 4 speeds, I'm going to open one up and see if the shift forks are the same. I also have late 280z 5 sp trans, maybe they are the same in them as well (short ears, 2 muffler hanger castings). I'm ordering both and see what shows up for Christmas

-

FS5W71B Rebuild Thread - Tips tricks and discoveries!

And dyslexia and or bad editing skills wins the award again for making sure nothing clear comes out of my fingers. FS5W71B is what I mean. Nothing special, just regular zx trans

-

FS5W71B Rebuild Thread - Tips tricks and discoveries!

Can't imagine that the shifter is the cause of not being able to get to 5th. They all work the same way. Would be a hoot if that was the actual problem. if the geometry of the shifter below the pin were a bit short and couldn't quite push it all the way in..... I won't be able to diagnose that particular 5sp until spring when I yard it out and exchange it for one of freshly rebuilt ones. I could give the guy a few different shifter styles to try and see if one of them magically works.

-

FS5W71B Rebuild Thread - Tips tricks and discoveries!

Tools: I hope I can edit this for a couple of days. Not going to list common stuff. Just stuff you may not have. 1. BAV attached to a BAB. (Large Vise 5 or 6" jaws, attached to Large sturdy workbench). You get to guess what BA stands for. 2. Bearing puller with splitters, large and small, with length extensions. Mine uses 3/8 course threads so I bought a bunch of Gr8 all-thread and coupler nuts. Cheap and strong enough. 3. 38mm open/box end wrench. Also 1-1/2 is just fine too. 4. Snap ring pliers. There are two thick stiff little suckers on the reverse counter gear shaft that if you don't have a proper fitting snap ring pliers, you will curse your life for hours . The tips I used are 0.090 and fit perfect. OTS makes them, sure there are many others. Don't buy cheap. see above. 5. T45 6pt star bit. 6. A press. For assembly, you may not NEED a press if you use the "heat the bearing in the oven", freeze the shaft in the freezer or snowbank, then tap together with maybe nothing more than a pipe and hammer. For disassembly bearing splitter plates and pullers do most. The main shaft has to be pushed out of the bearing in the intermediate plate, and if you had a tall enough press its easy. I'll show what I did instead below. 7. The right size magnet on a stick. Little, like 3/16 to get a couple balls out of holes. 8.

-

FS5W71B Rebuild Thread - Tips tricks and discoveries!

So first post about parts. Drivetrain.com has rebuild kits. DTS -BK104 in various forms with and without synchro's. Some have said the synchro's weren't great, but the Nissan ones if you can. Nissan can also supply all the bearings and bits. Few if any hard parts. EuroDat supplied this spreadsheet of Nissan Parts numbers. Tranny_Rebuild_FEB2012.pdf

-

FS5W71B Rebuild Thread - Tips tricks and discoveries!

Lucky me. I have about five speeds in my yard and in various cars, few of which I know much about. Parts come, parts go, you forget who you got them from, were they any good, blah blah blah I just went through a frustrating experience trying to do a 5 speed swap for a local Z guy. First 5 speed I grab is my favorite, a backup I've kept around for years in case mine blows up. It's an 82-83 close ratio zx five speed, you know the one, tall shift ears, one muffler hanging casting, nice tall 5th gearing. Drag it into the shop, stuff a shifter in it, can't do much but select 1 and 2, and neutral, but it's locked up. Input shaft only turns the output shaft in Neutral.... Huh????? Go grab the "next best" 5 speed. Shifts fine on the floor, all gears turn the output shaft. Stuff it in the car, go for a drive, can't get it in 5th! Just grinds. Oh crap. This spawns my thread about "I need a 5 speed close by!". So far only one offer, too far away. So. Time to man up and learn how to do a rebuild. Here we are. I really want my close ratio five speed working. I have another one in my dime that's making noises I don't like too. I'm replacing it with a C fresh C type with L bell housing, but I will be good for other projects. I showed this video in another prior thread. It's why the one 5 speed is locked up. Yeah, no kidding...... FS5W71B_bearing_problem .mp4

-

FS5W71B Rebuild Thread - Tips tricks and discoveries!

I'm in the process of rebuilding a one, maybe two, or three, not sure, FC5W71B transmissions. It's just about the LAST thing I have yet to do on (to?) a Datsun. Always thought it was too hard and needed too many special tools. It's not. I want to record details of what I found and did along the process, but not in the usual way. -I will NOT take a video of the whole process. There are plenty great ones on YouTube. I WILL record the URL's of any helpful video's I find to help centralize the source for those videos and maybe critique each one's strengths. -I will NOT add the 300 photos I will take along the way. I WILL take photos and add notes on the tricks and traps and useful organizational methods I found and used along the way. -I WILL make one post that lists ALL the tools I needed. Some I bought, some I modified, some I made, to help you to understand what you will need if you try this. This will either convince you can or CAN'T (or shouldn't) -I WILL encourage you to attempt this yourself. It is not hard, it is just very detail oriented. -I WILL list parts sources for parts I find, especially new sources. -I will make notes about commonality I find between the various 4 and 5 speeds, if that turns there are enough to mention. For example I need a 1-2 shift fork for a 82-83 trans. What other trans have the same fork? Any? Stuff like that. Now onto the good stuff

-

Transmission rebuild help

So I'm doing my homework and watching all the YouTubes (there are 3 excellent ones) and one of the "suggested for you"'s was one on how syncronizers work. I'm thinking, well, it's probably pretty basic, but let's watch it. One question I've had in this, is diagnosing what's wrong. Such as how do you know if you need new synchros? This video show's problems with synchros and how to tell what's wrong. Good thing to watch.

- Transmission rebuild help

-

Transmission rebuild help

I may be about to start a FS5W71B rebuild and this thread looks pretty handy. Looking at drivetrain.com, they seem to only have -A, and -C references to their parts, nothing or little about the B trans. When you look at the 280Z and 280ZX applications in the various sections, the 280zx appears in the A and C sections, which at least for North American cars, the 280ZX did not have the C trans. Which exact rebuild kit did you order? It sure looks like the DTS-BK104 series. Searching the site for FS5W71B, they list this https://www.drivetrain.com/parts-catalog/manual-transmission-rebuild-kits-and-parts/mrk100601-nissan-5-speed-fs5w71c-fs5w71b-overhaul-kit but the picture shows applications from 84 onward, ie a "C" kit. Just found Grannyknots thread, seems he ordered the BK104. It is about the only choice. Help!

-

What Electric Fuel Pump upgrade???

My personal favorite. Other than the correct pressure range, 35 gph flowrate, proven quiet operation, threaded fittings (no hose clamps), years of good service in several vehicles, a remarkable resemblence to the OEM pump, it also has an internal filter. https://www.facet-purolator.com/gold-flo/ Specifically the 40002E with these specs https://www.facet-purolator.com/tech-information/

-

Parts Wanted: Wanted. A Decent Nissan Z 5 speed

View Advert Wanted. A Decent Nissan Z 5 speed Well my stash of 5 speeds has dwidles to two. One that is locked up, and one that you can't get into 5th gear with power applied. Before I go off and source a C type and go through that process, doesn't anyone "close by" have a decent late 280 or 280ZX 5 speed they KNOW is in good condition? Would pay decent money for it. Let me know. Short ears, two muffler hangers, short ears one muffler hanger or long ears one muffler hanger is ascending order of preference, but WORKING and not in major need of bearings is much more important. BW turbo 5 speeds need not apply, not that desparate yet.... ? Thanks Advertiser zKars Date 11/26/2019 Price $400.00 Category Parts Wanted Year 1983 Model Z or ZX

-

Headlight Buckets - Left or Right...?

Yes! Teflon tape might work VERY well. Thank you! Couldn't get enough PC to stick to those bolts to make a difference.

-

Headlight Buckets - Left or Right...?

Must be a widespread disturbance in the headlight mounting related force. I'm dealing with this as well today. I plan on using M6 insert nuts to replace that plastic nut nonense. My dilemna at the moment is how to give the bolt friction with the threads in the insert so it stays put. I could use a spring like on the SU or most DCOE idle screws I suppose but I'm going to try powder coating the bolts and see if increasing the OD with the plastic coating adds the friction I so badly wish for. So much for "doing away with the plastic" nonsense I guess.... I'll let you know how it turns out. BTW, the Dorman part referenced above mounts in a square hole. Easy enough to create with a file from the existing 8mm hole. Would be a slick solution if it works

-

how to replace windshield washer pump motor?

Just gonna leave this here... And on Amazon.ca, $5.88 CAD with one wrong connector... If you want I'll change the one wrong connector and only charge you $20. CAD.

-

This is got me scratching my head.... Speedo Pinion?

?

-

This is got me scratching my head.... Speedo Pinion?

Assuming the old pinion worked before, you have the pinion housing in 180 degrees wrong. Typically there is one slot where that little hold down plate engages, but someone previous may have used the "other" pinion type and added his own slot to make it work. Have a look of there are two slots on yours there are two types, the slot is 180 diff from the other. The pinion is offset in the body so you have to have it oriented correctly or it will not engage.

Subscriber

Subscriber