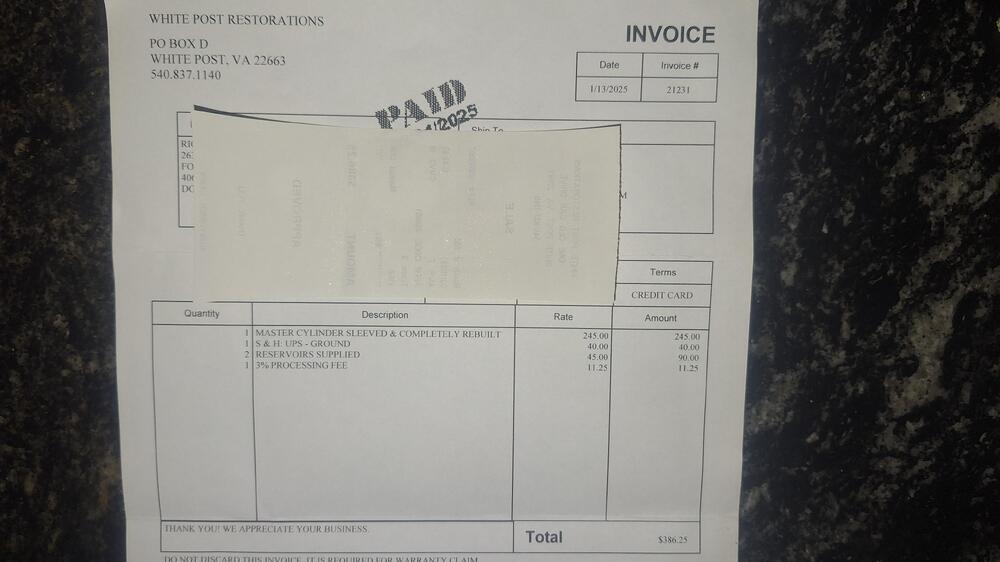

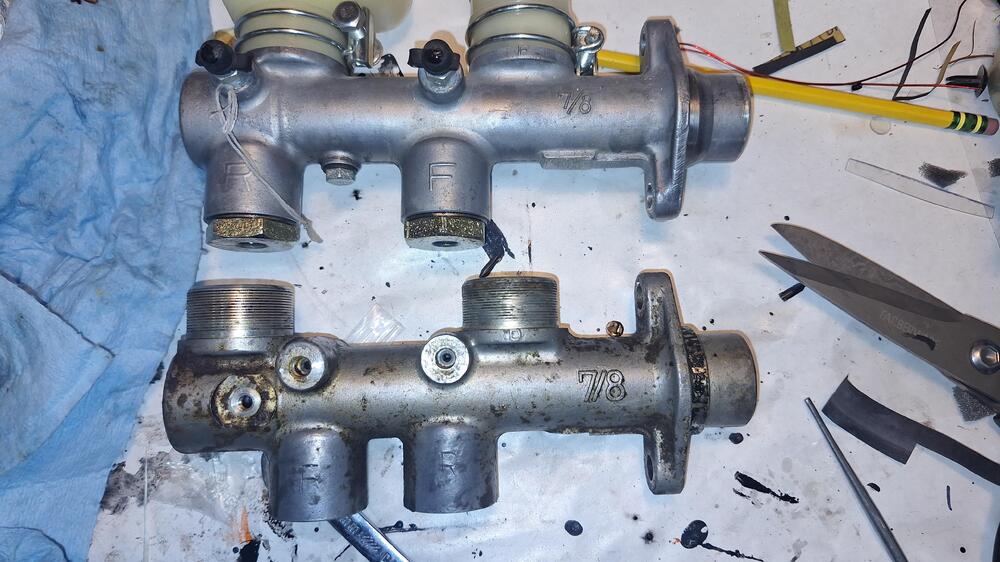

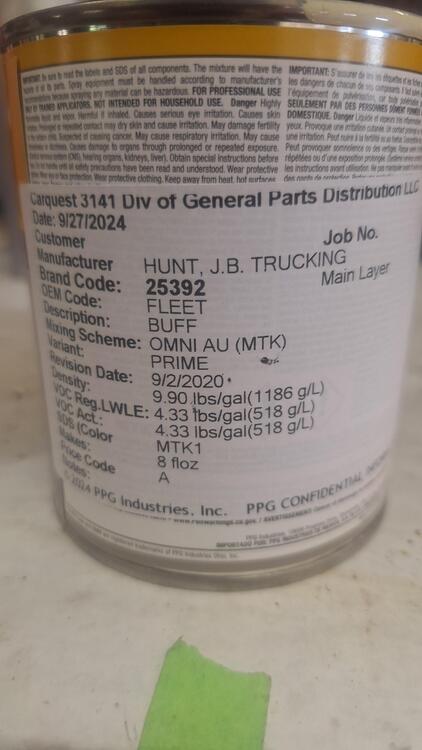

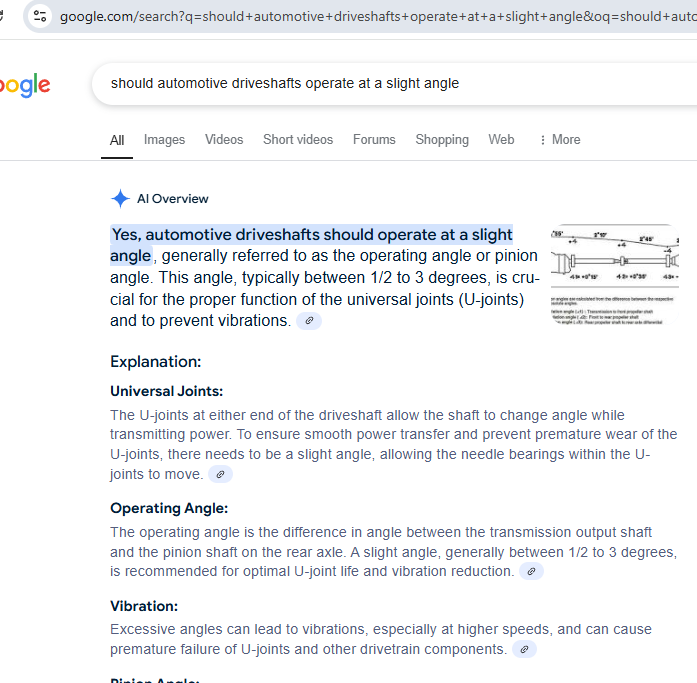

Installed the fan, 1st of many times, and the horns. I had the radiator re-cored back in 2021, it's been in a box in the loft for 4 years. I had the brake booster re-done as well in 2021. I tried to rebuild the brake master cylinder but...........I'm about to learn something. I have a few fenders off that parts car and measured and located the holes for the emblems, as well as the hatch. My hatch emblem holes were covered up, but I could find them from inside the hatch, underneath. So I removed the hatch. The fenders had no holes as the bottoms of them were replaced. The master cylinder on my car leaked, not only the copper sealing washers leaked, but was leaking back into the brake booster. Not a good situation with all this fresh nice paint. It was about this time I realized I don't even have the correct master cylinder on this car. The rear reservoir is going to the front and visa versa. That's the way I found it. Makes me wonder of it really makes any difference, this swap was done decades ago. It just so happened I got a master cylinder with my parts car, and it was the correct one. It had one good cap. Here's what an early cap looks like. Too late to stop now, haha, dang it, so I sent it to White Post Restorations. I installed it and guess what, it leaked...out the copper sealing washers where those big fittings are on the bottom. Because these new copper sealing rings are too hard, harder than they used to be, I heated them up to a glowing red, to anneal them, align the properties. I don't think it matters how you cool copper, quickly or slowly, the end result is the same. Sure enough it made them soft and they sealed.

Subscriber

Subscriber 3Points100Posts

3Points100Posts

Subscriber

Subscriber 2Points1,281Posts

2Points1,281Posts Subscriber

Subscriber 1Points2,733Posts

1Points2,733Posts